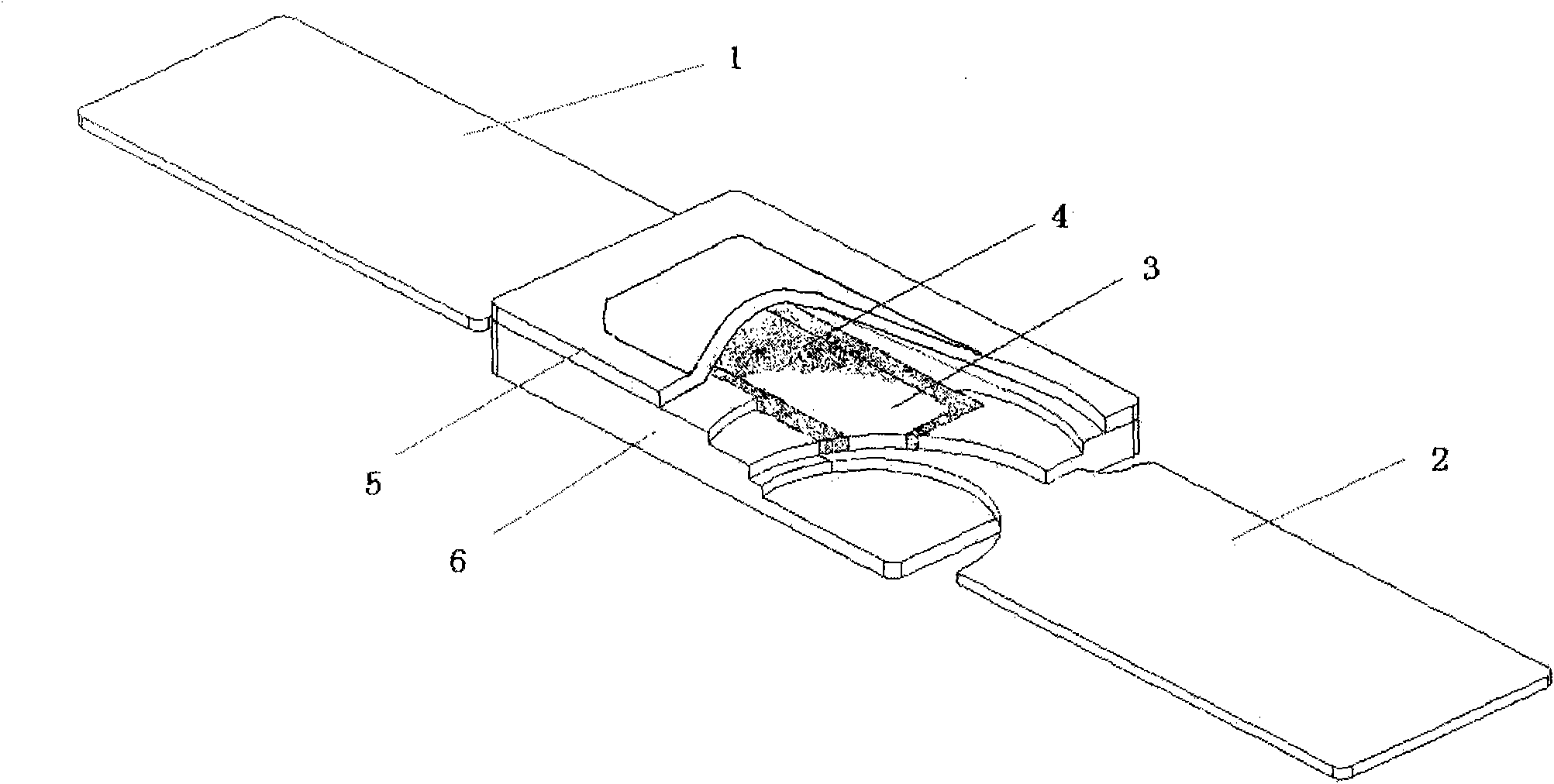

Temperature fuse and manufacturing method thereof

A technology of thermal fuse and manufacturing method, applied in fuse manufacturing, electrical components, electrical switches, etc., can solve the problems of flux leakage, many bonding interfaces, complex structure, etc., and achieve excellent sealing performance, simple manufacturing process, and simplified products. effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

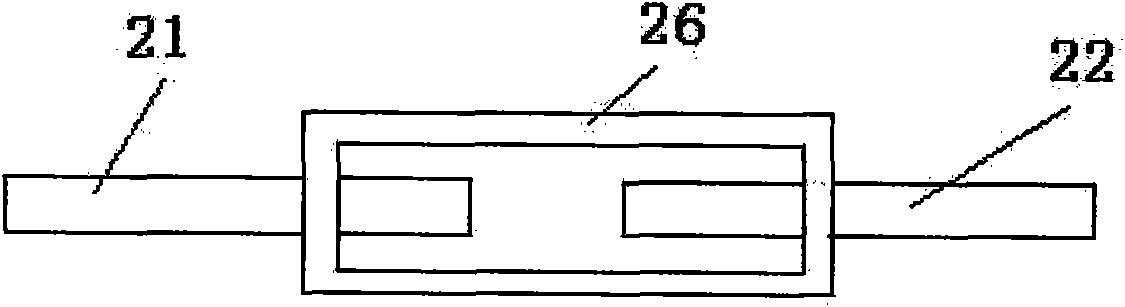

[0038] first step, such as Figure 2A As shown, two nickel strips 21 and 22 with a thickness of 0.1mm are placed in a mold in a straight line, the size of the nickel strips is 2mm*10mm, and the distance between the two ends is 1mm, and then the PET resin is injected into the injection molding machine to obtain the embedded strips at both ends. The box body 26 of shape metal electrode;

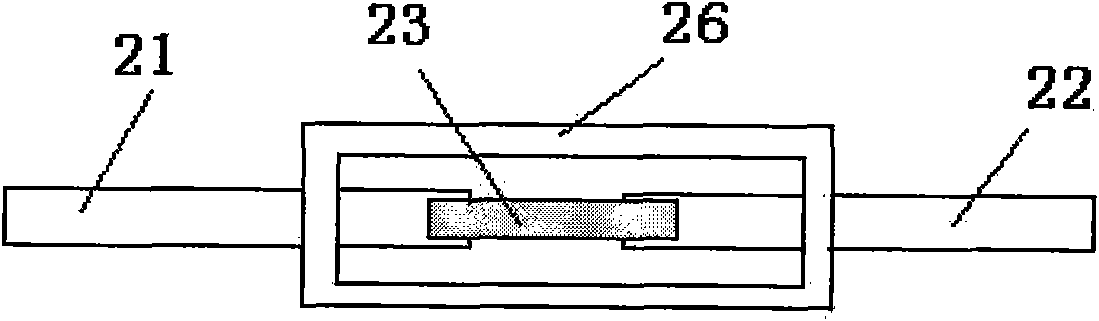

[0039] The second step, such as Figure 2B As shown, a low temperature fusible alloy wire 23 with a length of 2.5 mm is welded to the ends of nickel strips 21 and 22 by laser.

[0040] The third step, such as Figure 2C As shown, the flux 24 prepared by blending rosin, stearic acid and diethylamine hydrochloride is added dropwise around the fusible alloy wire 23 after being heated and melted.

[0041] The fourth step is to take a PET resin sheet with a thickness of 0.1mm, punch it into a small rectangular piece of 5mm×3mm by a punching machine as the cover plate 25, and then use ultrasonic w...

specific Embodiment 2

[0042] first step, such as Figure 3A As shown, two nickel strips 31 and 32 with a thickness of 0.1mm are arranged in a straight line in the mold, the size of the nickel strips is 2mm*10mm, and the distance between the two ends is 1mm, and then the PET resin is injected into the injection molding machine to obtain the embedded strips at both ends. The box body 36 of shape metal electrode;

[0043] The second step, such as Figure 3B As shown, a low-temperature fusible alloy wire 33 with a length of 2.5 mm is welded to the ends of nickel strips 31 and 32 by laser.

[0044] The third step, such as Figure 3CAs shown, take a PET resin sheet with a thickness of 0.1mm, and use a punch to punch it into a small rectangular piece of 5mm×3mm as the cover plate 35, and press an elliptical bulge in its middle part, and the height of the bulge is 0.3mm. The flux 34 prepared by blending rosin, stearic acid and diethylamine hydrochloride is filled in the raised part of the cover plate 35...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com