Novel process for producing valine

A valine and new process technology, applied in the new process field of valine production, can solve problems such as product quality fluctuation, low product yield, passive production, etc., achieve standard production process, reduce production cost, and reduce environmental protection pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

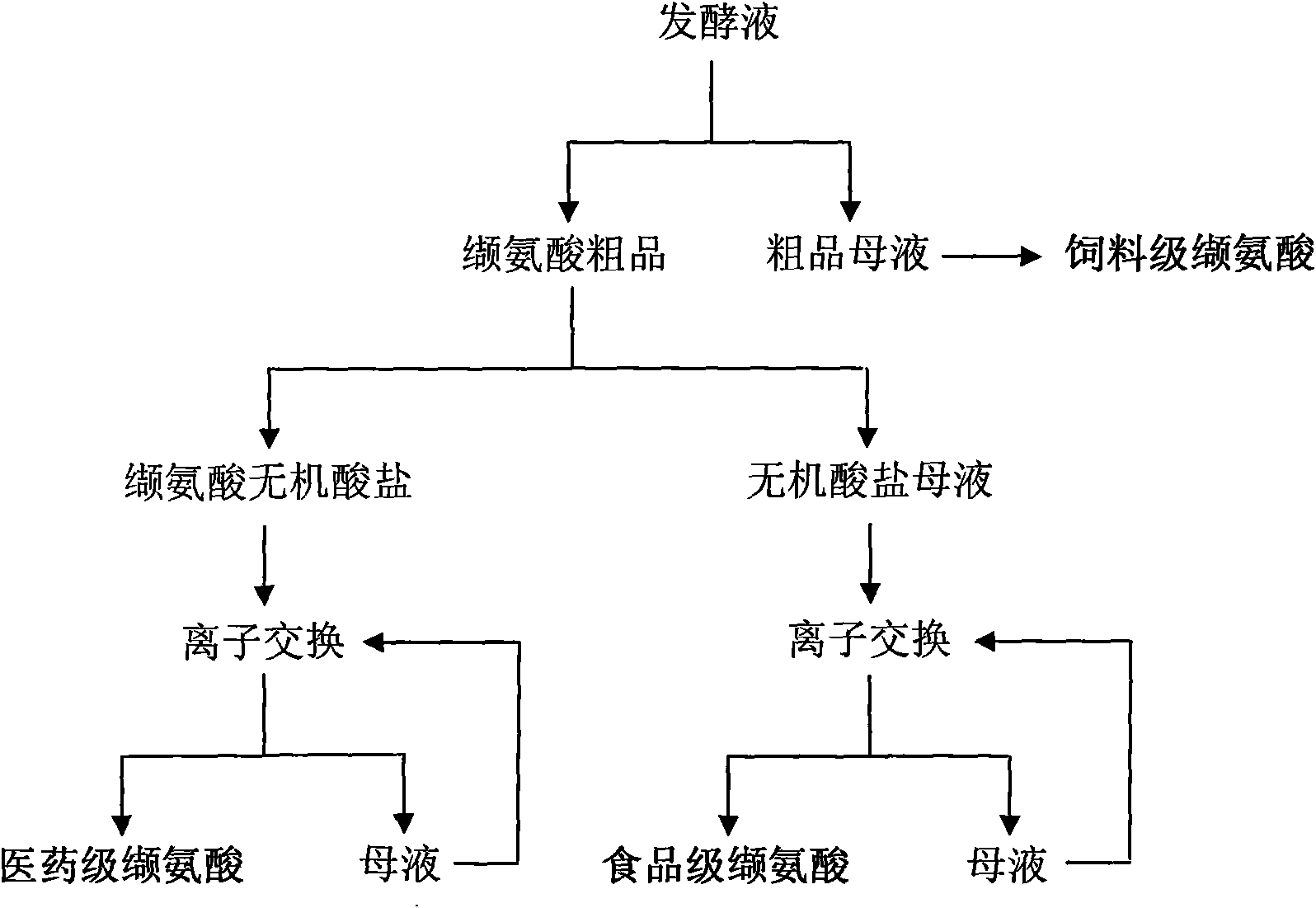

Method used

Image

Examples

Embodiment 1

[0016] 1) Preparation of crude valine and feed-grade valine: 70L of valine fermentation broth, with a content of 3.9%, was removed by ultrafiltration to remove macromolecular impurities such as bacteria, decolorized with activated carbon for injection, and then concentrated and crystallized under reduced pressure. Centrifuge to obtain the crude product of valine, 2.05kg of valine with a conversion purity of 100%, 7.15L of mother liquor, and a content of 9.5%, and the crude product mother liquor is spray-dried to obtain 0.92kg of feed grade valine with a content of 74%;

[0017] 2) Preparation of valine hydrochloride: slowly add the crude product into dilute hydrochloric acid with a volume of 35 L and a concentration of 6 mol / L, stir at 65°C until completely dissolved, then cool down to crystallize, and centrifuge to obtain valine hydrochloride and Valine hydrochloride mother liquor. Thin-plate chromatography was used to detect the purity of valine hydrochloride. If there were ...

Embodiment 2

[0026] 1), the preparation of valine crude product and feed grade valine

[0027] Valine fermented liquid 6.5L, content 4.2%. Macromolecular impurities such as bacteria were removed by ultrafiltration, decolorized by activated carbon for injection, concentrated and crystallized under reduced pressure, and centrifuged after cooling to obtain crude valine, 213g of valine with a conversion purity of 100%, 0.645L of mother liquor, content 9.3%, The crude product mother liquor was spray-dried to obtain 78.7g of feed grade valine with a content of 73.7%;

[0028] 2), preparation of valine hydrochloride

[0029] The crude product was slowly added to dilute hydrochloric acid with a volume of 3.4 L and a concentration of 6 mol / L, stirred at 70°C until it was completely dissolved, then cooled to crystallize, and centrifuged to obtain valine hydrochloride and valine hydrochloride mother liquor, thin plate layer Analyze and detect the purity of valine hydrochloride. If there are spots o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com