Device and method for high-quality recovery of fluorine from wet-process phosphoric acid tail gas

A wet-process phosphoric acid, high-quality technology, applied in separation methods, chemical instruments and methods, fluorosilicic acid, etc., can solve problems such as aggravating pipeline blockage and reducing the effect of exhaust gas scrubbing, avoiding pipeline blockage, achieving significant economic benefits, and operating stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

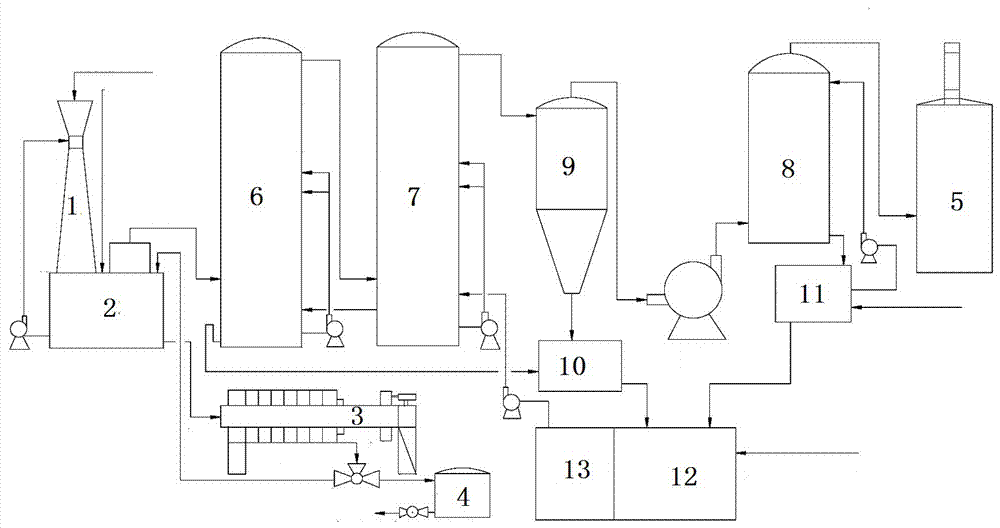

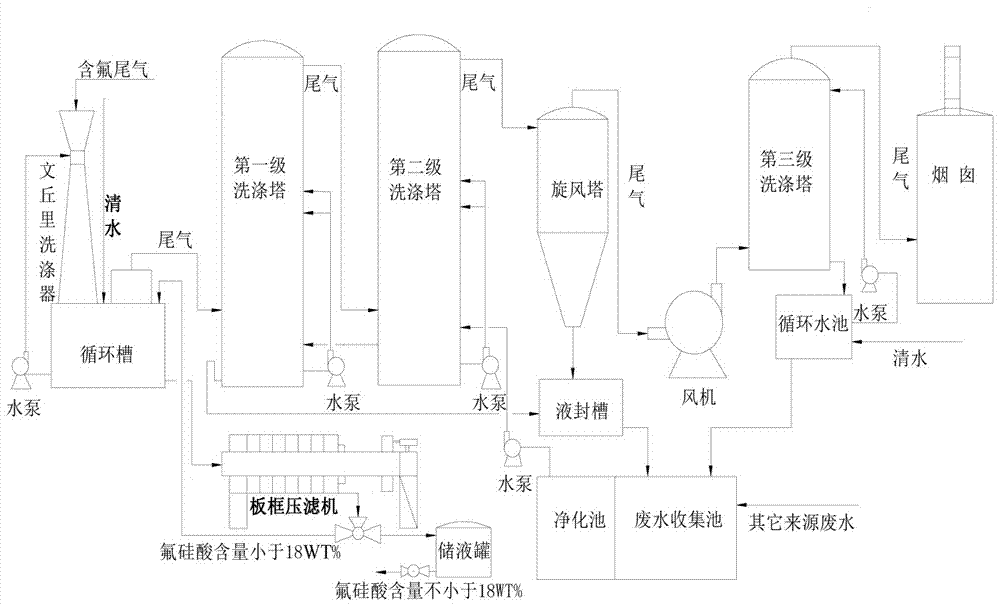

Image

Examples

Embodiment 1

[0033] A method for high-quality recovery of fluorine in wet-process phosphoric acid tail gas, comprising the following:

[0034] 1) The circulation tank below the Venturi scrubber is filled with clean water from mechanical cooling until the overflow of the circulation tank just flows out, and it is used as fluorine-containing tail gas to spray washing water. The spray water was circulated for 37 hours, and the content of fluosilicic acid in the circulation tank liquid was measured to be 23wt%. It was pumped into the plate and frame filter press for filtration, and the filtrate was input into the liquid storage tank to obtain a filter press liquid without particles of 12.90±0.20m 3 , the filtrate is sold.

[0035] 2) The circulation tank of the second-stage washing tower continuously pumps the defluoridated water (fluorine content <2.0%w / w) into the purification tank, and the water in the circulation tank circulates in the body for spray washing.

[0036] 3) The outlet of the...

Embodiment 2

[0041] A method for high-quality recovery of fluorine in wet-process phosphoric acid tail gas, comprising the following:

[0042] 1) The circulation tank below the Venturi scrubber is filled with clean water from mechanical cooling until the overflow of the circulation tank just flows out, and it is used as fluorine-containing tail gas to spray washing water. The spray water was circulated internally for 19 hours, and the liquid fluosilicic acid content in the circulation tank was measured to be 12wt%. It was pumped into a plate-and-frame filter press for filtration, and the filtrate was input into the circulation tank at the lower part of the Venturi scrubber for internal circulation as spray water, and added Stop replenishing water when the clear water reaches the overflow port of the circulation tank and just discharge the liquid; the content of fluosilicic acid in the circulation tank is measured as 21wt% after 17 hours of internal circulation, pumped into the plate and frame...

Embodiment 3

[0049] A method for high-quality recovery of fluorine in wet-process phosphoric acid tail gas, comprising the following:

[0050] 1) The circulation tank below the Venturi scrubber is filled with clean water from mechanical cooling until the overflow of the circulation tank just flows out, and it is used as fluorine-containing tail gas to spray washing water. The spray water was circulated for 32 hours, and the content of fluosilicic acid in the circulation tank liquid was measured to be 19wt%, pumped into the plate and frame filter press for filtration, and the filtrate was input into the liquid storage tank to obtain a filter press liquid without particles 13.20±0.20m 3 , the filtrate is sold.

[0051] 2) The circulation tank of the second-stage washing tower continuously pumps the defluoridated water (fluorine content <2.0%w / w) into the purification tank, and the water in the circulation tank circulates in the body for spray washing.

[0052] 3) The outlet of the circulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com