Method for resource utilization of graphene waste acid

A graphene and resource-based technology, applied in chemical instruments and methods, manganese sulfate, fluorosilicic acid, etc., can solve the problems of resource utilization of metal ions, inability to effectively reduce production costs, and high energy consumption of corrosion-resistant equipment. Achieve the effect of green environmental protection in the process, improve the quality score and reduce the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

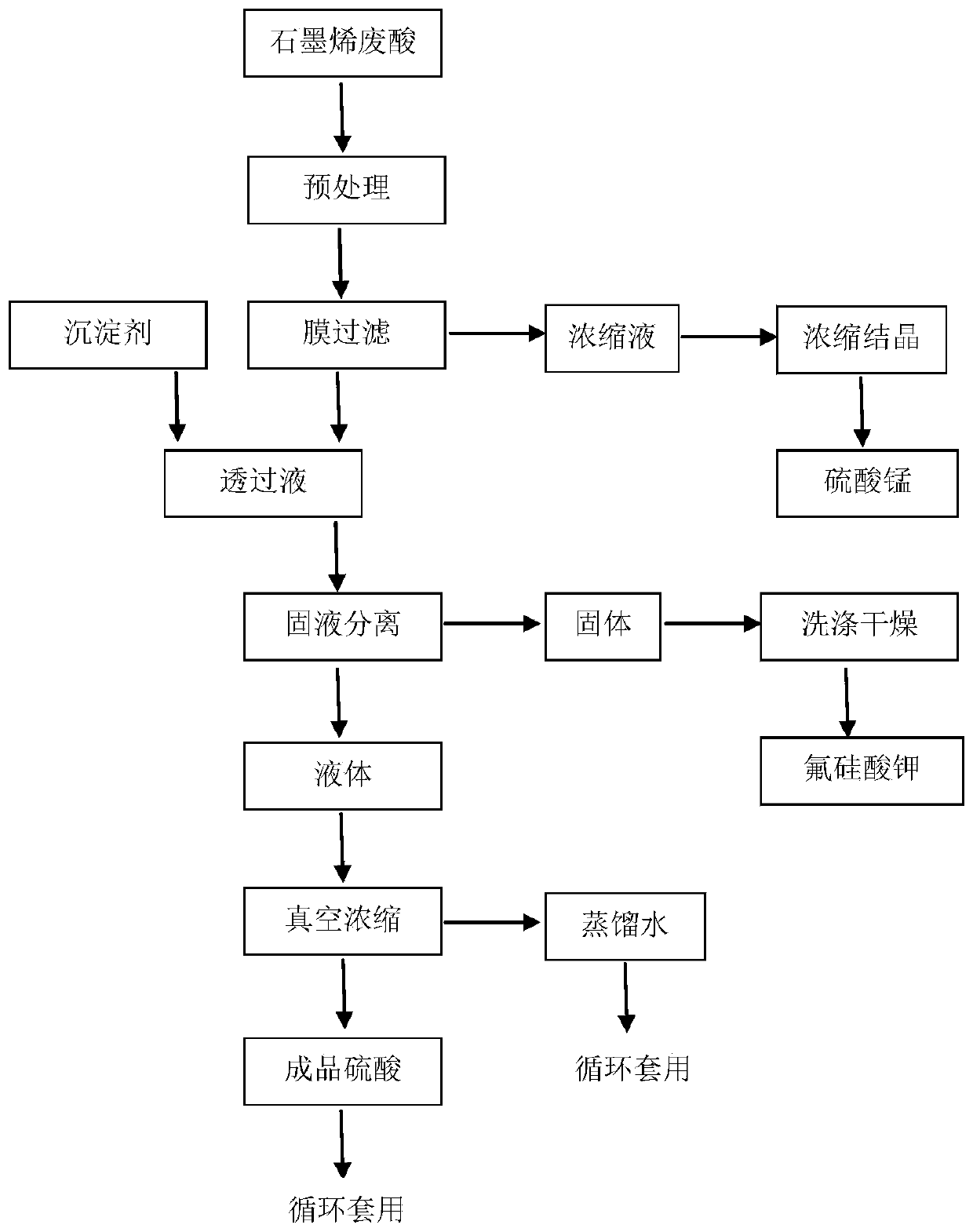

Image

Examples

Embodiment 1

[0033] Get graphene waste acid 500g, wherein the massfraction of sulfuric acid is 43.79%, the massfraction of potassium sulfate is 3.14%, and the massfraction of manganese sulfate is 2.72%.

[0034] Pretreatment of waste acid: Add 400g of water to the waste acid to dilute it until the mass fraction of sulfuric acid is less than 25%. The diluted waste acid is removed by ultrafiltration to remove suspended particles and macromolecular impurities;

[0035] Membrane filtration: the pretreated waste acid is treated with aromatic polyamide nanofiltration membrane to obtain concentrate and permeate. The mass fraction of manganese sulfate in the permeate is analyzed and detected to be 0.036%. After the concentrate is collected, it is concentrated and crystallized to obtain manganese sulfate ;

[0036] Precipitation treatment: add fluorosilicic acid to the above permeated liquid according to the molar ratio of potassium sulfate to fluorosilicic acid of 1:1, carry out precipitation reac...

Embodiment 2

[0039] Get graphene waste acid 500g, wherein the massfraction of sulfuric acid is 42.18%, potassium sulfate concentration is 3.56%, and manganese sulfate concentration is 2.38%.

[0040] Pretreatment of waste acid: add 400g of water to the waste acid to dilute it until the mass fraction of sulfuric acid is less than 25%. The diluted waste acid is removed by a combination of coarse filtration and ultrafiltration to remove suspended particles and macromolecular impurities;

[0041] Membrane filtration: the pretreated waste acid is treated with aromatic polyamide nanofiltration membrane to obtain concentrated liquid and permeate, and the mass fraction of manganese sulfate in the permeate is analyzed and detected to be 0.025%. After the concentrated liquid is collected, it is concentrated and crystallized to obtain manganese sulfate ;

[0042] Precipitation treatment: add fluorosilicic acid to the above permeated liquid according to the molar ratio of potassium sulfate to fluorosi...

Embodiment 3

[0045] Get graphene waste acid 500g, wherein the massfraction of sulfuric acid is 24.11%, potassium sulfate concentration is 4.27%, and manganese sulfate concentration is 5.61%.

[0046] Pretreatment of waste acid: use a combination of coarse filtration and ultrafiltration to remove suspended particles and macromolecular impurities in waste acid;

[0047] Membrane filtration: the pretreated waste acid is treated with aromatic polyamide nanofiltration membrane to obtain concentrated liquid and permeate. The mass fraction of manganese sulfate in the permeate is analyzed and detected to be 0.048%. After the concentrated liquid is collected, it is concentrated and crystallized to obtain manganese sulfate ;

[0048] Precipitation treatment: add fluorosilicic acid to the above-mentioned permeated liquid according to the molar ratio of potassium sulfate to fluorosilicic acid of 1:1, carry out precipitation reaction under the conditions of stirring, reaction temperature 65°C, and reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com