Device and method for preparing potassium fluosilicate and nitric acid by using fluorine-containing nitric acid etching solution

A technology of potassium fluorosilicate and etching solution, which is applied in the direction of fluorosilicic acid, nitric acid, nitrogen oxides/oxo acids, etc., can solve the problems of continuous production operation difficulty and increased production cost, and facilitate large-scale production , obvious economic benefits, realize the effect of waste resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

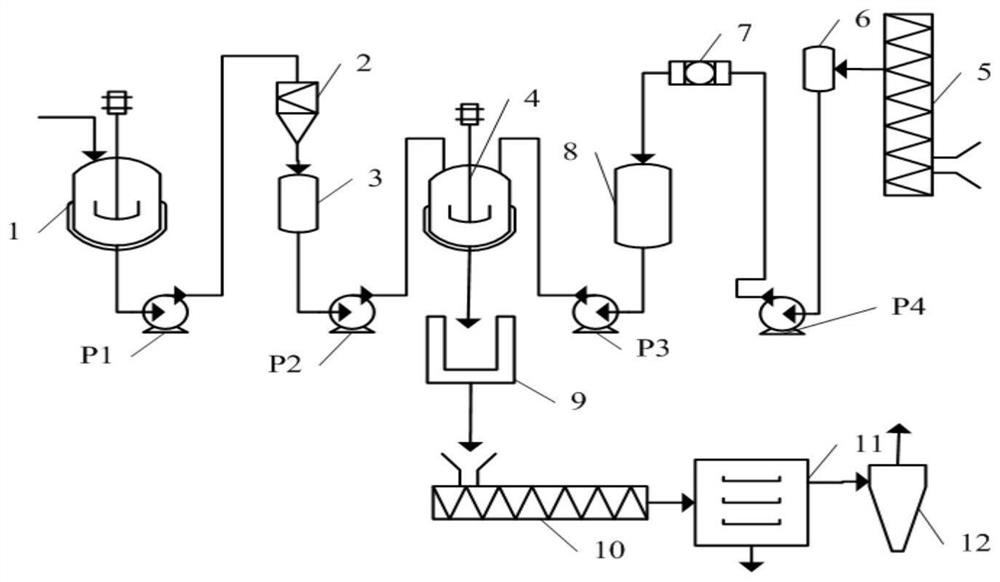

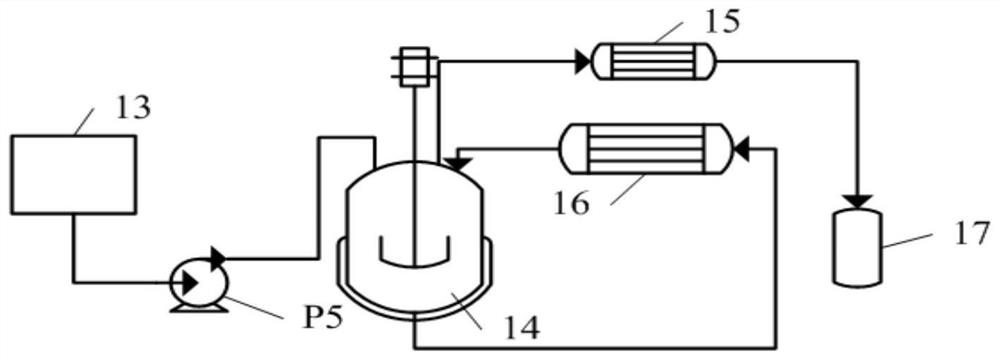

[0033] see figure 1 The device provided in this embodiment to prepare potassium fluorosilicate and nitric acid by using fluorine-containing nitric acid etching solution includes an etching solution pretreatment system, a potassium fluorosilicate recovery system, and a nitric acid evaporation recovery system; the potassium fluorosilicate recovery system includes sequentially connected The potassium fluorosilicate preparation unit and the potassium fluorosilicate drying unit; the etching solution pretreatment system is connected with the potassium fluorosilicate preparation unit; the nitric acid evaporation recovery system is connected with the potassium fluorosilicate preparation unit.

[0034] In this embodiment, the etchant pretreatment system includes a first reaction kettle 1, a silicon slag thickener 2 and a precipitation tank 3 which are connected in sequence; the precipitation tank 3 is connected to a potassium fluorosilicate preparation unit.

[0035] In the present emb...

Embodiment 2

[0045] Based on the preparation device of embodiment 1, it utilizes fluorine-containing nitric acid etchant to prepare potassium fluorosilicate and the method for nitric acid comprising the following steps:

[0046] 1) The fluorine-containing nitric acid etching solution enters the etching solution pretreatment system, and silicon dioxide is added through stirring and solid-liquid separation to obtain a fluorine-containing silicon nitric acid solution;

[0047] 2) The fluorine-containing silicon nitric acid solution in step 1) is reacted with a saturated potassium nitrate solution in the potassium fluorosilicate preparation unit, and after filtration, the crude potassium fluorosilicate product and a mixed solution containing nitric acid and potassium nitrate are obtained; the crude fluorosilicate The potassium fluorosilicate product is passed through the potassium fluorosilicate drying unit to obtain the potassium fluorosilicate product;

[0048] 3) After the mixed solution co...

Embodiment 3

[0061] With concrete application, illustrate the method utilizing nitric acid and potassium fluorosilicate prepared by fluorine-containing nitric acid etchant, specifically as follows:

[0062] 1) Take 1000L of fluorine-containing nitric acid (100g / L of fluorine ion) etchant and place it in the first reaction kettle 1, add 59kg of 90% silicon dioxide, and stir for 2 hours; after the reaction, pass through the first feeding pump P1 Pour into the silicon slag thickener 2 to separate and remove suspended solids, and the separated solution enters the sedimentation tank 3 to collect for later use;

[0063] 2.1) Take 99% potassium nitrate and transport it to the potassium nitrate dissolving tank 6 through the screw feeder 5 for dissolving, then pass the dissolved potassium nitrate through the potassium nitrate filter 7 through the first liquid inlet pump P4 and then enter the potassium nitrate semen tank 8 Obtain saturated potassium nitrate solution;

[0064] 2.2) Take 200L of satu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com