Waste acid resource utilization process

A technology of resource utilization and process, which is applied in the field of resource utilization of waste acid, can solve the problems of total nitrogen exceeding the standard and high treatment cost, and achieve the effect of reducing treatment cost, improving economic benefits and realizing resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

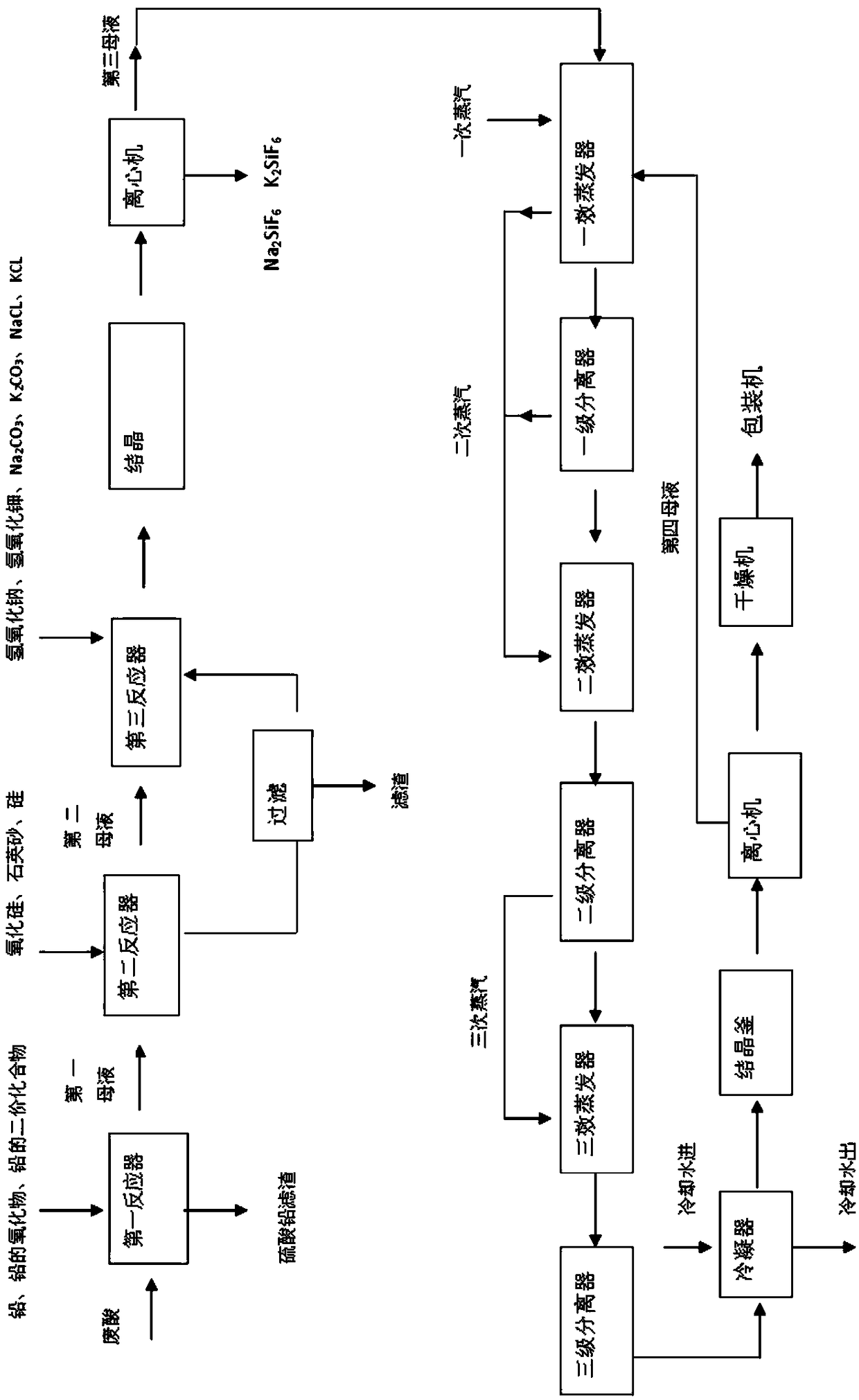

[0031] A resource utilization process of waste acid, such as figure 1 shown, including the following steps:

[0032] (1) Add the waste liquid produced by the electronics industry into the first reactor, then add the precipitating agent, add the filter to filter after fully stirring the reaction, obtain the lead sulfate filter residue and the first mother liquor, and separate the lead sulfate filter residue;

[0033] (2) The first mother liquor enters the second reactor, and one or more of carbon dioxide, quartz sand, and silicon are added into the second reactor, and the reaction temperature is 15° C. to obtain fluosilicic acid and the second mother liquor;

[0034] (3) The second mother liquor enters the third reactor, adds alkali or salt in the third reactor, reacts at a temperature of 15°C to obtain a reaction product, transfers the reaction product to a crystallization kettle for crystallization and obtains crystals and the third mother liquor, transferring the mixture of...

Embodiment 2

[0044] A resource utilization process of waste acid, such as figure 1 shown, including the following steps:

[0045] (3) Add the waste liquid produced by the electronics industry into the first reactor, then add the precipitating agent, add the filter to filter after fully stirring the reaction, obtain the lead sulfate filter residue and the first mother liquor, and separate the lead sulfate filter residue;

[0046] (4) The first mother liquor enters the second reactor, and one or more of carbon dioxide, quartz sand, and silicon is added to the second reactor, and the reaction temperature is 80° C. to obtain fluosilicic acid and the second mother liquor;

[0047] (3) The second mother liquor enters the third reactor, adds alkali or salt in the third reactor, reacts at a temperature of 90°C to obtain a reaction product, transfers the reaction product to a crystallization kettle for crystallization and obtains crystals and the third mother liquor, transferring the mixture of th...

Embodiment 3

[0057] A resource utilization process of waste acid, such as figure 1 shown, including the following steps:

[0058] (5) Add the waste liquid produced by the electronics industry into the first reactor, then add the precipitating agent, add the filter to filter after fully stirring the reaction, obtain the lead sulfate filter residue and the first mother liquor, and separate the lead sulfate filter residue;

[0059] (6) The first mother liquor enters the second reactor, and one or more of carbon dioxide, quartz sand, and silicon are added to the second reactor, and the reaction temperature is 45° C. to obtain fluosilicic acid and the second mother liquor;

[0060] (3) The second mother liquor enters the third reactor, adds alkali or salt in the third reactor, reacts at a temperature of 55°C to obtain a reaction product, transfers the reaction product to a crystallization kettle for crystallization and obtains crystals and the third mother liquor, transferring the mixture of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com