Resource separation and recycling method of aluminum ash

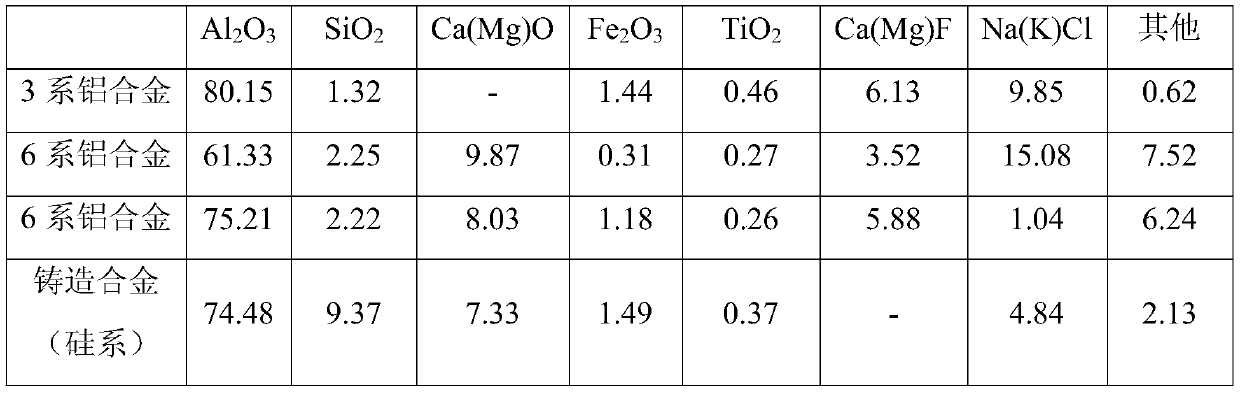

A technology of separation, recovery and recycling, which is applied in the field of recycling and processing of hazardous waste solid materials, and can solve the problems of low purity of fluorine-containing alumina, ineffective removal, complicated process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Prepare the aluminum ash after washing (chemical composition is Al by mass percentage 2 o 3 54.2%, SiO 2 1.5%, Al13.5%, AlN 16%, Fe 2 o 3 0.3%, Ca(Mg)O+Ca(Mg)F 2 11%, others 3.5%); prepare a sodium hydroxide solution with a mass concentration of 15 to 35%; the amount of sodium hydroxide solution is based on the Al, AlN and SiO in NaOH and washed aluminum ash 2 Complete reaction, and excess 10-50%;

[0047] Sodium hydroxide solution is placed in the reactor, and under the condition of stirring, the aluminum ash after washing is added in batches to the reactor one by one, and the Al and AlN in the aluminum ash after washing react with NaOH to generate hydrogen and Ammonia, hydrogen and ammonia are discharged from the exhaust pipe of the reactor and collected; when the washed aluminum ash is added to the reactor in batches, the bubbles generated by the reaction are controlled to not overflow the reactor;

[0048] When all the washed aluminum ash is added to the r...

Embodiment 2

[0054] Method is with embodiment 1, and difference is:

[0055] Fe in primary filter residue 2 o 3 The mass percentage content is ≤0.3%, and after drying, it is used as the alumina raw material when the aluminum electrolytic cell is roasted and started.

Embodiment 3

[0057] Method is with embodiment 1, and difference is:

[0058] Fe in primary filter residue 2 o 3 The mass percentage of >0.3%, analyze the Fe in the filter residue once 2 o 3 , CaO and MgO content; the primary filter residue is pickled in hydrochloric acid with a mass concentration of 10-25%, so that the Fe in it 2 o 3 , CaO and MgO react with hydrochloric acid and dissolve, then filter to obtain pickling filter residue; the amount of hydrochloric acid is based on HCl and Fe in the primary filter residue 2 o 3 , CaO and MgO complete reaction shall prevail; then the pickling filter residue is dried and used as the alumina raw material when the aluminum electrolytic cell is roasted and started.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com