Wet-process phosphoric acid technology and fluosilicic acid processing method free of fluorine-containing exhaust gas emission

A technology of wet-process phosphoric acid and fluosilicic acid, which is applied in fluosilicic acid, chemical instruments and methods, sustainable manufacturing/processing, etc., and can solve problems such as air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

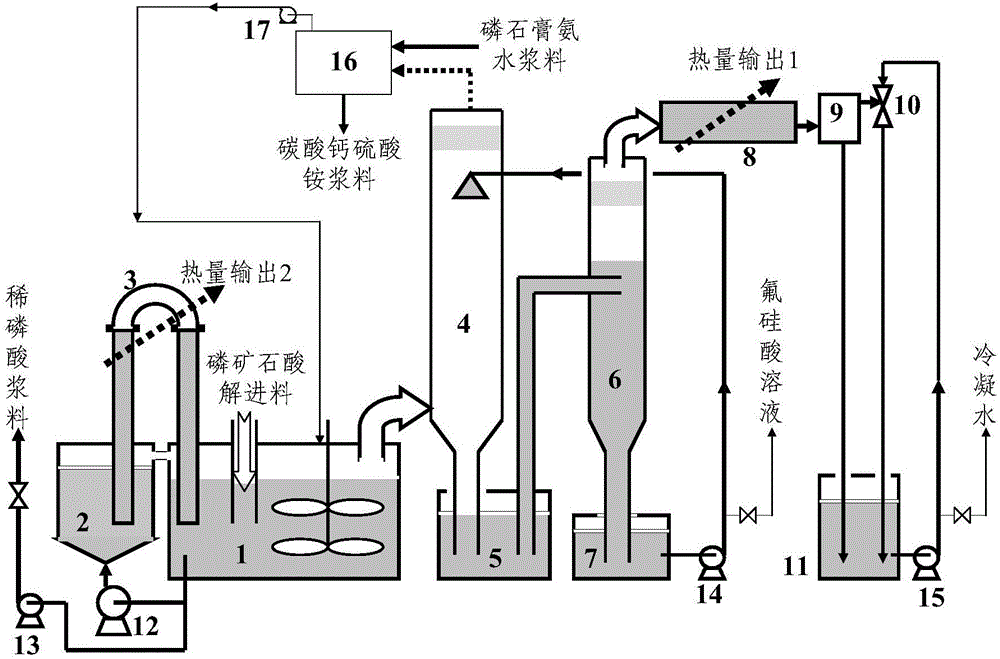

Method used

Image

Examples

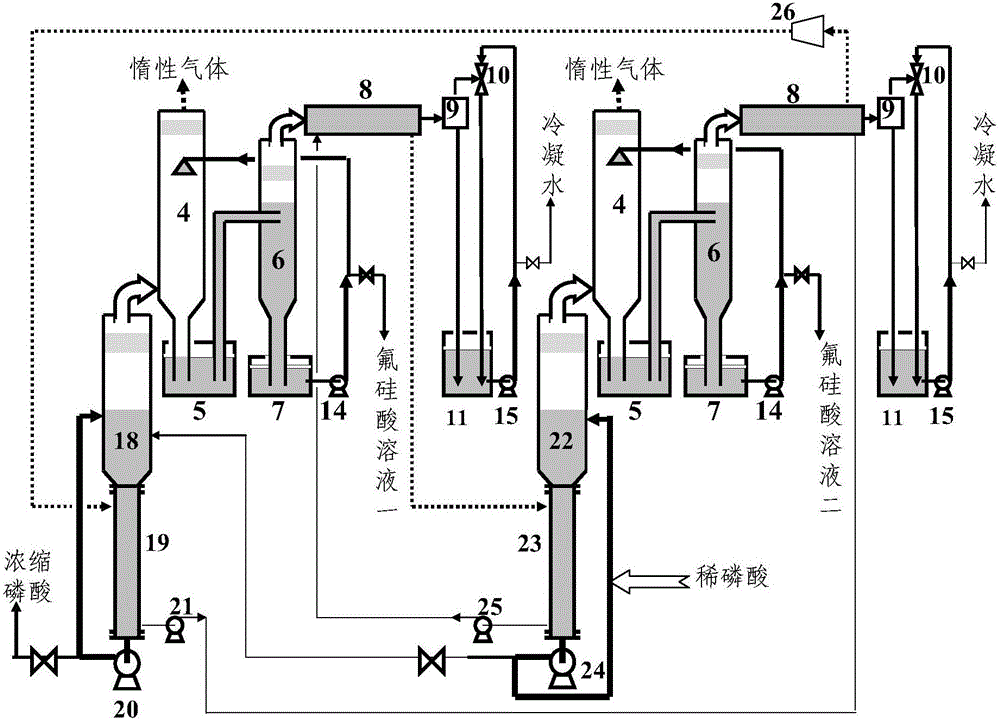

Embodiment 2

[0019] Embodiment 2: annual production of 50,000 tons of concentrated wet-process phosphoric acid (P 2 o 5 ). Raw material dilute phosphoric acid 31300 kg / h, containing P 2 o 5 22%, containing F 1.59%, temperature 45°C, concentrated phosphoric acid containing P 2 o 5 48%. Production of H without external heat source and recovery of fluorine escaped by evaporation 2 SiF 6 Fluorosilicic acid with a content of 15.0 m% or more.

[0020] as attached figure 2 As shown, the raw material dilute phosphoric acid is added from between the second-effect circulation pump 24 and the second-effect evaporation tank 22, and in this circulation loop, it is heated to 48~50°C by the tube side of the second-effect heater, evaporated and concentrated in the second-effect evaporation tank to contain P 2 o 5 31~32%, sent to the first-effect evaporator 18 through the outlet branch pipeline of the second-effect circulating pump 24 to continue evaporation and concentration. The fluorine-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com