Online cleaning method for off-gas pipe in fluosilicic acid concentration system

A concentration system and tail gas pipe technology, applied in the direction of fluosilicic acid, cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of gas phase pipe blockage, affecting the continuous and stable operation of the device, labor and time, etc., so as to avoid the impact and save The cost of maintenance and cleaning, and the effect of avoiding dead ends of pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

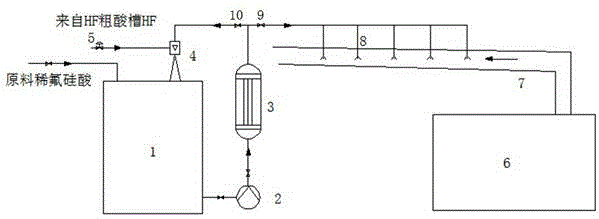

[0016] An online cleaning method for tail gas pipes of a fluosilicic acid concentration system, comprising the following steps:

[0017] (1) Acid dispensing: first introduce dilute fluosilicic acid with a mass concentration of 25% of the raw material, which accounts for 70% of the liquid level of the acid dispensing tank 1 (volume 7m??), as the acid dispensing mother liquor; determine the pre-prepared hydrofluoric acid When the mass concentration is 12%, start the circulation pump 2 to pass the dilute fluorosilicate mother liquor through the cooler 3 and then enter the Venturi 4 for full reflux operation. After stabilization, the HF flow control valve 5 can be opened to introduce crude acid HF, and the flow rate is controlled at 1m 3 / h, the temperature of acid mixing tank 1 does not exceed 40°C, stop the entry of crude acid HF after the liquid level of acid mixing tank 1 reaches 80%, and the acid mixing is completed;

[0018] (2) Cleaning: When the tail gas pipe of the...

Embodiment 2

[0020] An online cleaning method for tail gas pipes of a fluosilicic acid concentration system, comprising the following steps:

[0021] (1) Acid dispensing: first introduce dilute fluosilicic acid with a mass concentration of 20% of the raw material, which accounts for 70% of the liquid level of the acid dispensing tank 1 (volume 7m??), as the acid dispensing mother liquor; determine the pre-prepared hydrofluoric acid The mass concentration is 17%, and the circulating pump 2 is started to pass the dilute fluorosilicate mother liquor through the cooler 3 and then enters the Venturi 4 to spray for full reflux operation. After stabilization, the HF flow control valve 5 can be opened to introduce crude acid HF, and the flow rate is controlled at 1.5m 3 / h, the temperature of acid distribution tank 1 is not higher than 40°C, and the liquid level of acid distribution tank 1 reaches 85% to stop the crude acid HF from entering, and the acid distribution is completed;

[0022] ...

Embodiment 3

[0024] An online cleaning method for tail gas pipes of a fluosilicic acid concentration system, comprising the following steps:

[0025] (1) Acid dispensing: first introduce dilute fluosilicic acid with a mass concentration of 15% of the raw material, accounting for 70% of the liquid level of the acid dispensing tank 1 (volume 7m??), as the acid dispensing mother liquor; determine the pre-prepared hydrofluoric acid The mass concentration is 22%, and the circulation pump 2 is started to pass the dilute fluorosilicate mother liquor through the cooler 3 and then enters the Venturi 4 to spray for full reflux operation. After stabilization, the HF flow control valve 5 can be opened to introduce crude acid HF, and the flow rate is controlled at 2m 3 / h, the temperature of acid mixing tank 1 is not higher than 40°C, and the liquid level of acid mixing tank 1 reaches 90% to stop the crude acid HF from entering, that is, the acid mixing is completed;

[0026] (2) Cleaning: When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com