Method for recycling fluorine resources in phosphate fertilizer production

A production method and resource recovery technology, applied to chemical instruments and methods, fluosilicic acid, phosphorus compounds, etc., can solve problems that cannot be explained, and achieve the effects of reducing waste, increasing economic benefits of resources, and saving mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The present embodiment adopts the mode of continuous circulation treatment, and the percentage % in the present embodiment, unless otherwise specified, all refers to mass percentage;

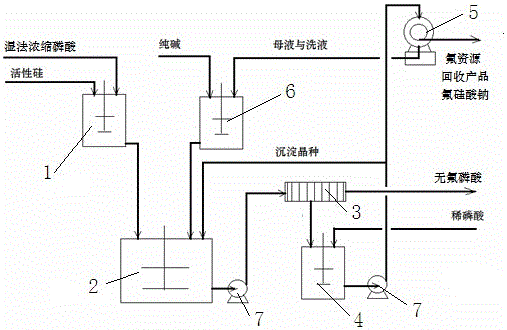

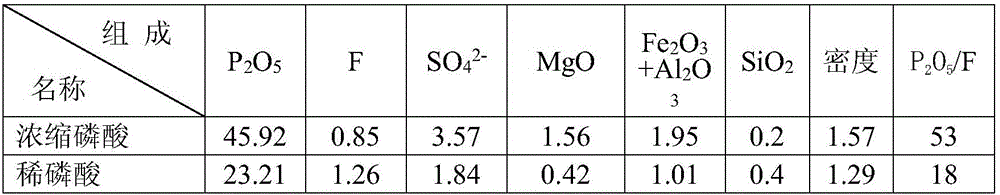

[0034] see figure 1, the concentrated phosphoric acid 50000kg / h of wet-process phosphoric acid (concentrated phosphoric acid composition is shown in Table 1) is pumped into silicon dissolving tank 1 by pump, after adding the active silica of 140kg / h to dissolve, send in the fluorine precipitation tank 2, add containing The mixed solution 3157kg / h of 1400kg / h of the seed crystal slurry 1400kg / h of sodium fluorosilicate 20% and the 17% sodium dihydrogen phosphate and phosphoric acid that alkali solution tank 6 sends, carries out stirring precipitation reaction at normal temperature 60 minutes and crystallizes;

[0035] Reaction generates material 54697kg / h in the fluorine precipitation tank 2, sends in the filter press 3 by pump 7 and carries out solid-liquid separation, obtains filtrate 53...

Embodiment 2

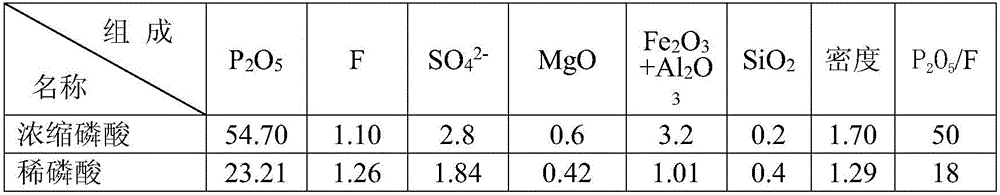

[0041] As shown in the figure, pump 100.00t / h of concentrated phosphoric acid (see Table 2 for the composition) into the silicon dissolution tank 1, add 0.42t / h of active silicon oxide for dissolution, then send it into the defluorination precipitation tank 2, add 2.80t / h of the seed slurry containing 20% sodium fluorosilicate and 5.92t / h of the mixed solution of 17% sodium dihydrogen phosphate and phosphoric acid sent by the alkali dissolution tank 6, and stirred and precipitated at room temperature for 60 minutes;

[0042] 109.14t / h of the reaction-generated material in the defluorination precipitation is sent to the filter press 3 by the pump 7 for solid-liquid separation, and 106.64t / h of the filtrate (52.92%P 2 o 5 , 0.06% F), and a filter cake containing 80% solids 2.50t / h; the filtrate is the recovered semi-finished product defluorinated phosphoric acid, which is used for the production of fertilizer phosphate or feed phosphate; the filter cake is sent to the sodium f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com