Method for recycling fluorine in neutralized slurry of industrial monoammonium phosphate

A technology of industrial monoammonium phosphate and a recovery method, which is applied in the field of fluorine recovery in industrial monoammonium phosphate neutralization slurry, can solve the problem that the industrial monoammonium phosphate neutralized slurry cannot be completely consumed, restricts industrial monoammonium phosphate production, industrial The problems such as parking of the monoammonium phosphate plant have achieved the effects of low processing cost, improved quality and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

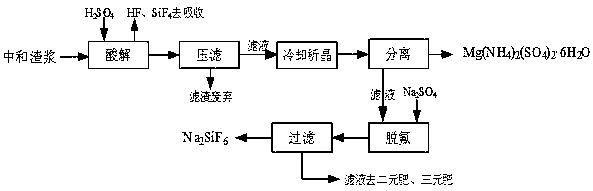

Method used

Image

Examples

Embodiment 1

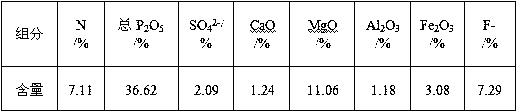

[0031] The solid content of the neutralized slurry is controlled at about 40%, and 98% concentrated sulfuric acid is added to the slurry according to 80% of the solid phase mass of the slurry, and the reaction is stirred at 90°C for 1 h. Filter to obtain acid hydrolysis filtrate, P in this acid hydrolysis filtrate 2 o 5 The content of phosphorus and fluorine is about 15%, the content of fluorine is about 2.2%, and the acid hydrolysis rate of phosphorus and fluorine are both above 99%.

Embodiment 2

[0033] The acid hydrolysis filtrate separated and obtained in Example 1 is cooled, crystallized, and filtered at a temperature of 5°C-10°C to obtain the acid hydrolysis filtrate for removing impurities. The main component of the separated crystals is ammonium magnesium sulfate hexahydrate. After analysis, the main content Above 99%.

Embodiment 3

[0035] Add the impurity-removing acid hydrolysis filtrate obtained in Example 2, according to the fluorine content in it, add anhydrous sodium sulfate solid in a molar ratio of 6:1 for reaction, the reaction temperature is 40°C, and the reaction time is 0.5h. After filtering and washing, fluosilicic acid is obtained. sodium. The filtered filtrate can be prepared into water-soluble fertilizer, and also used as raw material of binary fertilizer and ternary fertilizer. The purity of sodium fluorosilicate is 98.7%, and the yield of fluorine is 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com