Washing and absorbing device and method for wet process phosphoric acid production tail gas

A tail gas scrubbing and wet-process phosphoric acid technology, which is applied in separation methods, chemical instruments and methods, fluosilicic acid, etc., can solve the problems of reduced reaction speed, easy plugging of packing systems, and high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

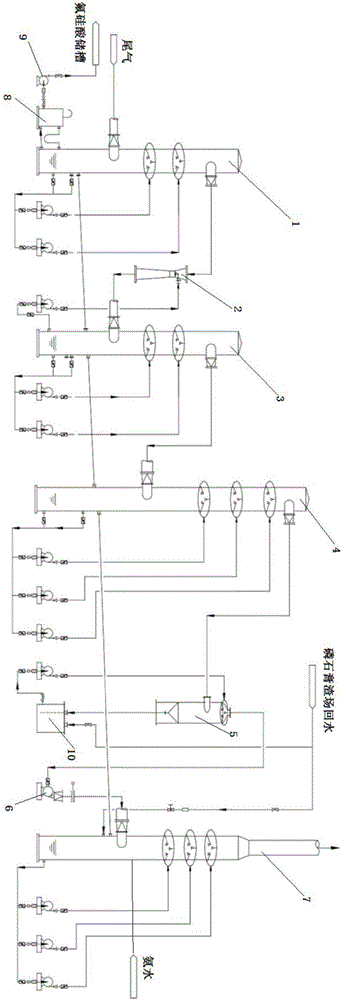

[0060] Tail gas scrubbing and absorbing tower 7. The backwater volume of phosphorus supplemented gypsum slag field is 150-200m 3 / h, after washing and absorbing the tail gas, it is measured by a flow meter, divided into 10m 3 / h into the tail gas scrubbing and absorbing system in the order of "trifluorine scrubbing and absorbing tower 4→difluorine scrubbing and absorbing tower 3→monofluorine scrubbing and absorbing tower 1". The remaining water is pumped to the backwater large circulation pool of the phosphogypsum slag yard.

[0061] The high and low liquid level control butterfly valves of the inlet pipes of all tower pumps are in the open state. Adopt trifluorine scrubbing absorption tower spray washing circulation pump, difluorine scrubbing absorption tower spray scrubbing circulation pump and monofluorine scrubbing absorption tower spray scrubbing circulation pump respectively to trifluorine scrubbing absorption tower 4, difluorine scrubbing absorption tower 3 and a The ...

Embodiment 2

[0079] Tail gas scrubbing and absorbing tower 7, trifluorine scrubbing and absorbing tower 4, difluorine scrubbing and absorbing tower 3 and monofluorine scrubbing and absorbing tower 1 are intermittent independent spray washing. Use the overflow pipeline of the spray washing circulation pump of the corresponding trifluorine washing absorption tower, the overflow pipeline of the spray washing circulation pump of the difluorine washing absorption tower and the overflow pipeline of the spray washing circulation pump of the monofluorine washing absorption tower 4. The difluorine scrubbing and absorbing tower 3 and the monofluorine scrubbing and absorbing tower 1 carry out excess water replenishment.

[0080] (1) Open the backwater valve of the slag field and measure by the flow meter to replenish water in the tail gas scrubbing and absorbing tower 7. When the liquid level of the tail gas scrubbing and absorbing tower 7 exceeds 90%, open the tail gas scrubbing and absorbing tower 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com