Centrifugal double-rotating super-gravity flue gas purification device

A flue gas purification and supergravity technology, which is applied in gas treatment, separation methods, and dispersed particle separation, etc., can solve the problems of exhaust gas blockage in supergravity, low static and dynamic pressure of flue gas, and difficulty in passing through packing, etc., and achieve high-speed rotation The effects of less vibration, low rotational energy consumption and high desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

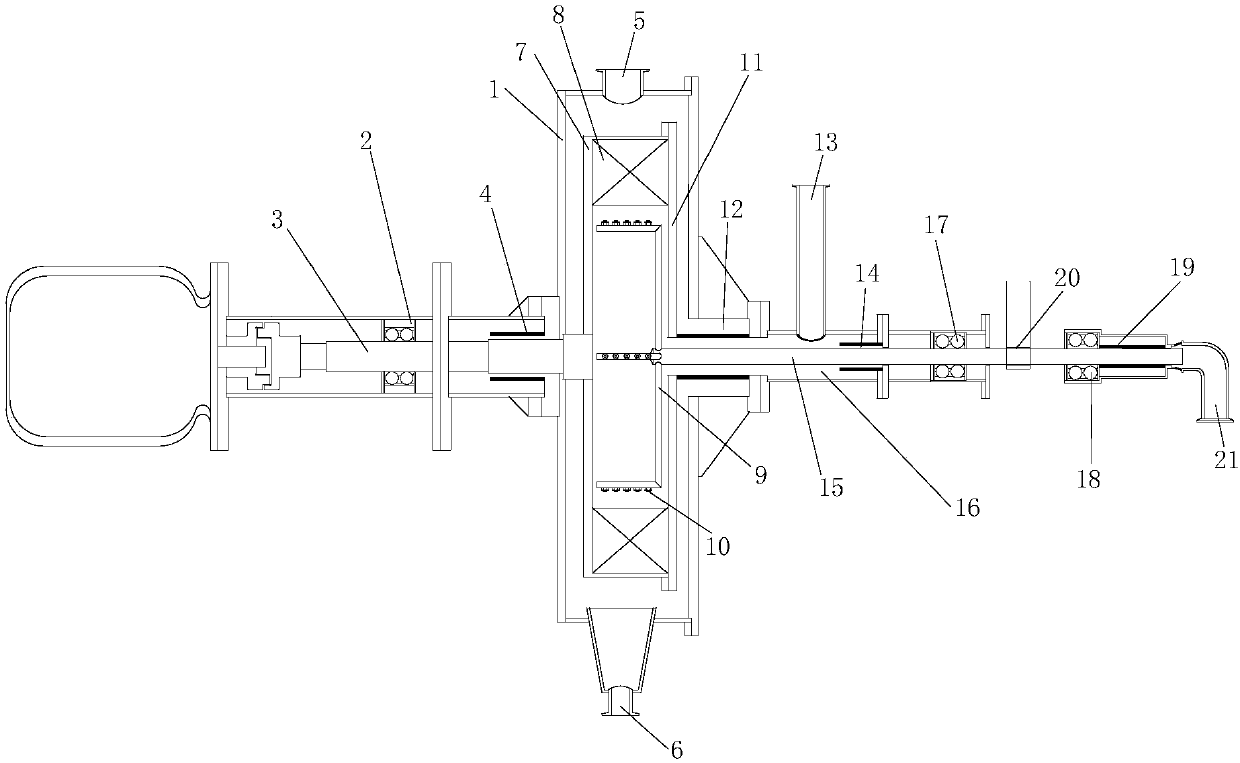

[0022] Such as figure 1 As shown, the present invention is a centrifugal double-rotation supergravity flue gas purification device, comprising a housing 1 provided with a gas inlet 5, a gas outlet 13 and a liquid outlet 6, the middle part of the housing 1 is a central rotating reaction zone, and the gas The inlet 5 and the gas outlet 13 are separated. In this embodiment, the gas inlet 5 is set at the top of the central rotating reaction zone, and the liquid outlet 6 is set at the bottom of the central rotating reaction zone. The central rotating reaction zone communicates with the gas outlet 13 through the gas channel 16 .

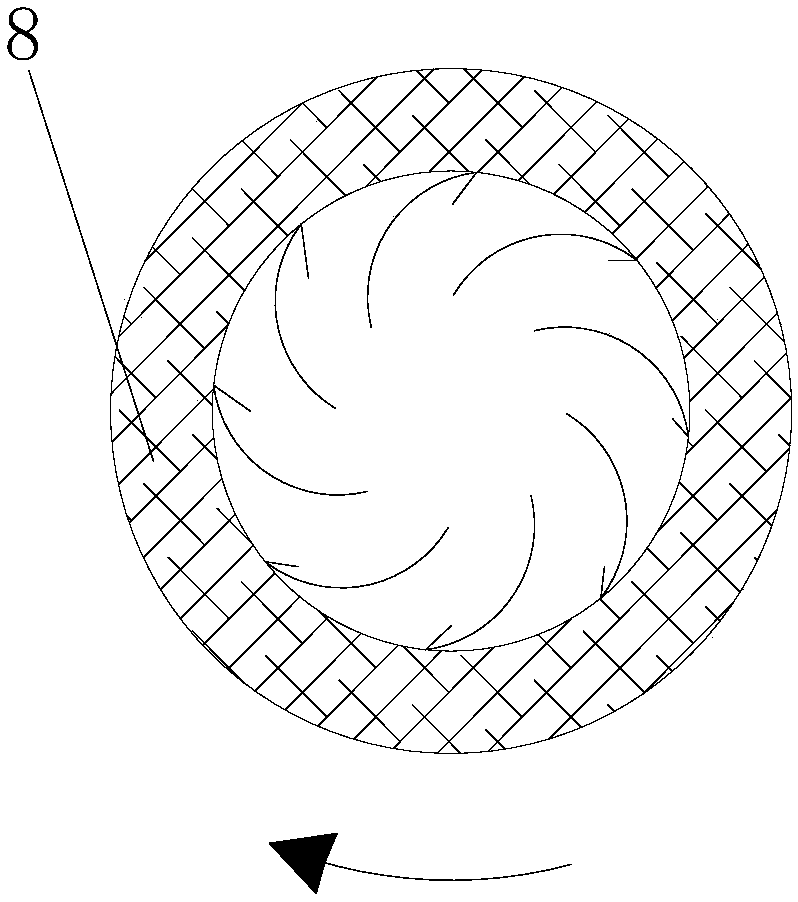

[0023] The central rotating reaction zone is provided with a rotating disc 7 and packings 8 annularly distributed on the rotating disc 7. In the middle of the inner ring of the packing 8, a hollow multi-directional rotating rocker arm 9 and a multi-directional rotating rocker arm 9 are provided. Each liquid spray head 10, the rotating disc 7 and the mult...

Embodiment 2

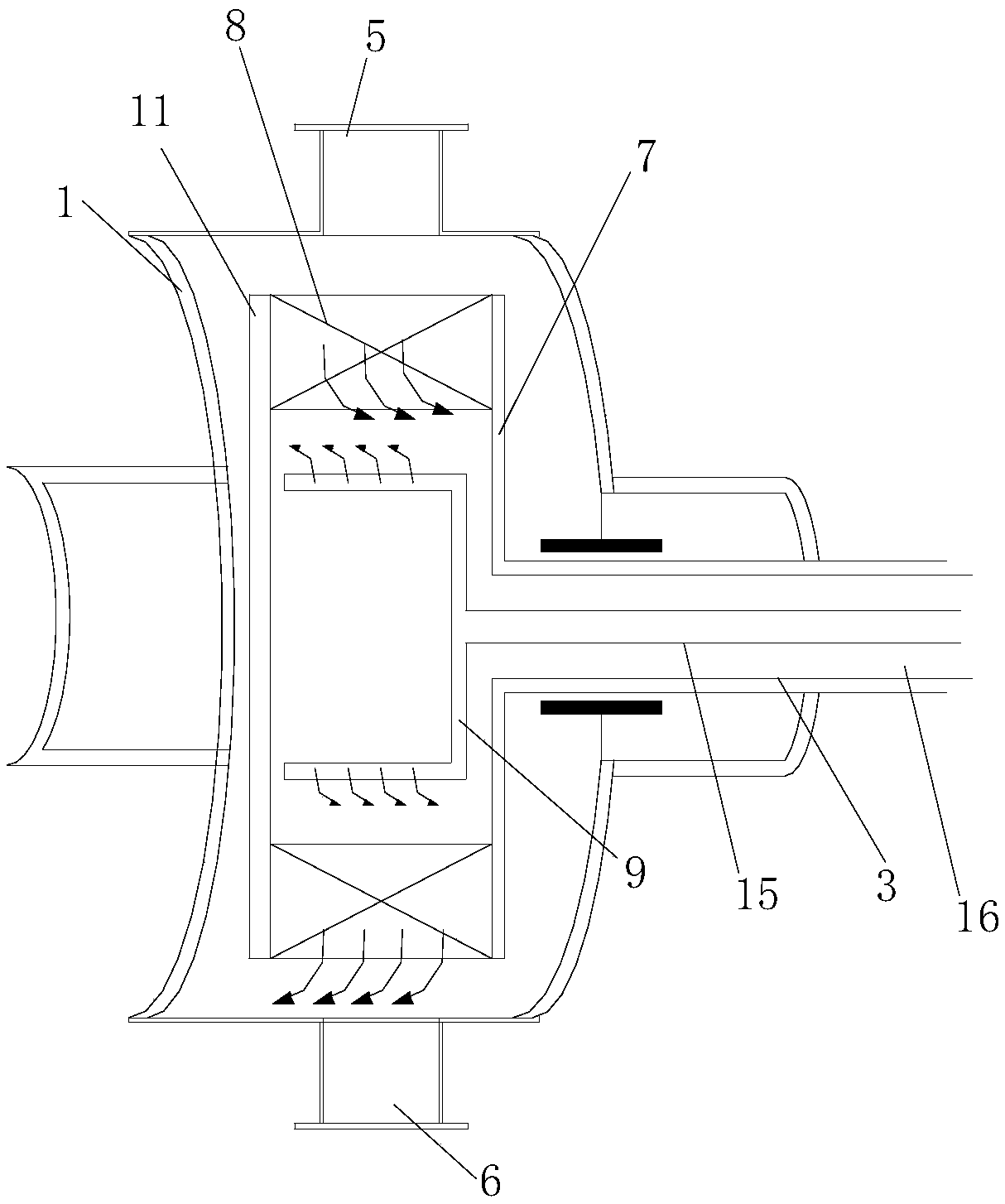

[0031] Such as image 3 As shown, in this embodiment, the rotating shafts of the rotating disk 7 and the multi-directional rotating rocker arm 9 are respectively arranged in the same direction. At this time, both the first rotating shaft 15 and the second rotating shaft 3 are hollow, and the first rotating shaft 15 and the second rotating shaft 3 are concentric and arranged inside the second rotating shaft 3 . The gap between the first rotating shaft 15 and the second rotating shaft 3 forms a gas channel 16 .

[0032] Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com