Method for preparing potassium fluoborate by recycling mother liquor

A technology of potassium fluoroborate and mother liquor, which is applied in the field of mother liquor recycling to prepare potassium fluoroborate, which can solve the problems of high processing cost, high cost, and environmental pollution, and achieve the effects of increasing yield, avoiding environmental pollution, and improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

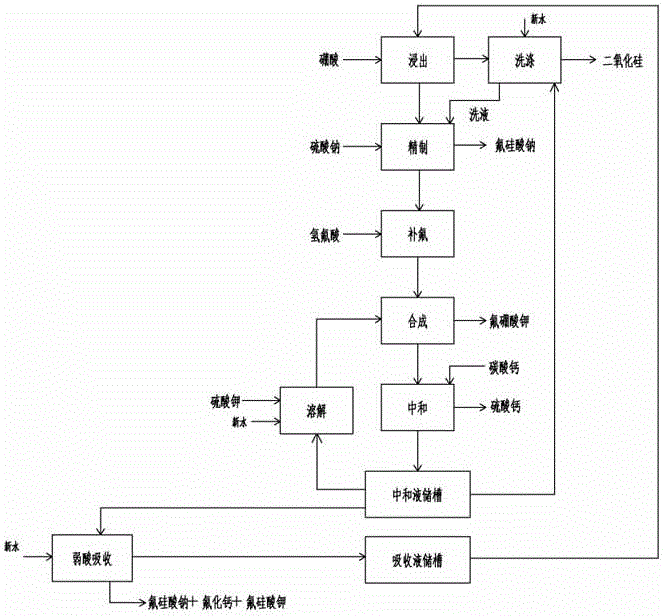

[0035] see figure 1 A method for preparing potassium fluoroborate by recycling mother liquor of the present embodiment comprises the following steps:

[0036] (1) After the hydrofluoric acid production system undergoes reaction, pre-purification, purification, condensation, and sulfuric acid absorption, it enters the weak acid absorption device for tail gas absorption, and injects new water into the weak acid absorption device until the content of fluosilicic acid in the system is 205g After the content of / L, hydrofluoric acid is 45g / L, the solution is put into the absorption liquid storage tank;

[0037] (2) Pump the absorption liquid in the absorption liquid storage tank into the leaching tank, preheat to 91°C and keep the constant temperature, start stirring, add solid boric acid until the mass ratio of fluorine and boron in the solution is 8:1, and the feeding is completed After reacting for 2 hours, filter the above leaching solution to obtain crude fluoroboric acid sol...

Embodiment 2

[0046] see figure 1 , a method for preparing potassium fluoroborate by recycling mother liquor in this embodiment comprises the following steps:

[0047] (1) After the hydrofluoric acid production system undergoes reaction, pre-purification, purification, condensation, and sulfuric acid absorption, it enters the weak acid absorption device for tail gas absorption, and injects new water into the weak acid absorption device until the content of fluosilicic acid in the system is 150g After the content of / L, hydrofluoric acid is 5g / L, the solution is put into the absorption liquid storage tank;

[0048] (2) Pump the absorption liquid in the absorption liquid storage tank into the leaching tank, preheat to 100°C and keep constant temperature, start stirring, add solid boric acid until the mass ratio of fluorine and boron in the solution is 11:1, and the feeding is completed After reacting for 3 hours, filter the above leaching solution to obtain crude fluoroboric acid solution an...

Embodiment 3

[0057] see figure 1 , a method for preparing potassium fluoroborate by recycling mother liquor in this embodiment comprises the following steps:

[0058] (1) After the hydrofluoric acid production system undergoes reaction, pre-purification, purification, condensation, and sulfuric acid absorption, it enters the weak acid absorption device for tail gas absorption, and injects new water into the weak acid absorption device until the content of fluosilicic acid in the system is 450g / L, after the content of hydrofluoric acid is 100g / L, put the solution into the absorption liquid storage tank;

[0059] (2) Pump the absorption liquid in the absorption liquid storage tank into the leaching tank, preheat to 80°C and keep constant temperature, start stirring, add solid boric acid until the mass ratio of fluorine and boron in the solution is 6:1, and the feeding is completed After reacting for 0.5h, filter the above leaching solution to obtain crude fluoroboric acid solution and sili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com