Comprehensive utilizing method for fluorine-containing silicon dioxide

A technology of silicon dioxide and calcium silicon, applied in silicon halide compounds, chemical instruments and methods, fluosilicic acid, etc., can solve the problems of large dosage of chemical agents, ecological environment, agriculture and human health damage, strong dependence, etc. problem, to achieve the effect of excellent phosphorus adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

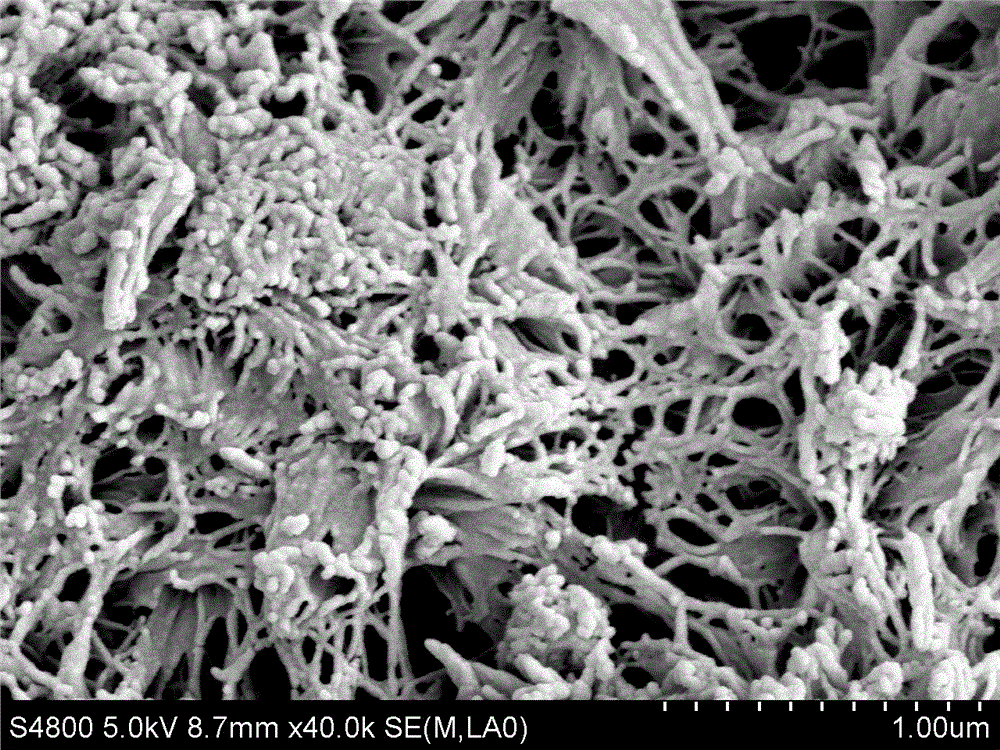

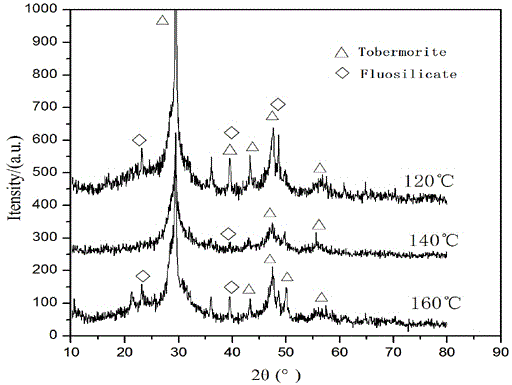

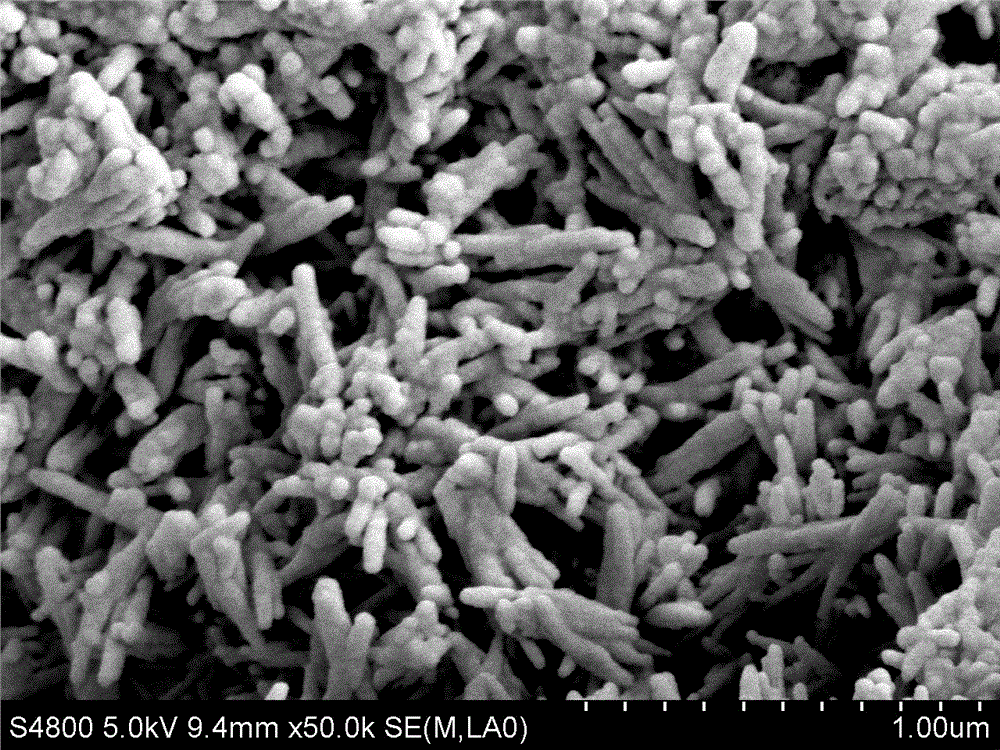

[0038] The silica used in Example 1 is industrially represented by H 2 SiF 6 It is the fluorine-containing silica by-produced in the preparation of fluorine salt as raw material, and the silica contains 5% soluble fluoride (calculated as F). Weigh fluorine-containing silicon dioxide and industrial grade calcium hydroxide respectively according to the calcium-silicon molar ratio of 0.5, and mix them with water according to the liquid-solid ratio (ratio of liquid mass to solid mass) of 10:1, and stir and mix Put the mixture into the reactor for static hydrothermal reaction, the reaction temperature is 140°C, the reaction pressure is 0.5MPa, and the reaction time is 8 hours. Dry to obtain phosphorus adsorbent. The proportion of each component in the obtained phosphorus adsorbent is n(CaF 2 +CaSiF 6 ):n(CaSiO 3 )=4:25, n(CaSiF 6 ):n(CaF 2 )=1:5; the specific surface area measured by BET nitrogen adsorption method is 140m2 / g.

Embodiment 2

[0040] The silicon dioxide used in example 2 is industrially Na 2 SiF 6 It is the fluorine-containing silicon dioxide by-produced in the preparation of fluorine salt as the raw material, and the silicon dioxide contains 10% soluble fluoride (calculated as F). Weigh fluorine-containing silicon dioxide and industrial grade calcium hydroxide respectively according to the calcium-silicon molar ratio of 0.7, mix them with water according to the liquid-solid ratio (ratio of liquid mass to solid mass) of 20:1, and stir and mix The mixture was placed in a reactor for hydrothermal reaction, the reaction temperature was 140°C, and the reaction time was 12 hours. After the hydrothermal treatment was completed, it was cooled to room temperature, separated by filtration, and the filtered solid was dried to obtain a phosphorus adsorbent. The proportion of each component in the obtained phosphorus adsorbent is n(CaF 2 +CaSiF 6 ):n(CaSiO 3 )=11:50, n(CaSiF 6 ):n(CaF 2 )=2:5; the specifi...

Embodiment 3

[0042] The silicon dioxide used in Example 3 is industrially known as (NH 4 ) 2 SiF 6 It is the fluorine-containing silica by-produced in the preparation of fluorine salt as raw material, and the silica contains 15% soluble fluoride (calculated as F). Weigh fluorine-containing silicon dioxide and industrial grade calcium hydroxide respectively according to the calcium-silicon molar ratio of 0.7, and mix them with water according to the liquid-solid ratio (ratio of liquid mass to solid mass) of 10:1, and stir and mix The mixture was placed in a reactor for hydrothermal reaction, the reaction temperature was 160°C, and the reaction time was 10 hours. After the hydrothermal treatment was over, it was cooled to room temperature, separated by filtration, and the filtered solid was dried to obtain a phosphorus adsorbent. The proportion of each component in the obtained phosphorus adsorbent is n(CaF 2 +CaSiF 6 ):n(CaSiO 3 )=7:20, n(CaSiF 6 ):n(CaF 2 )=1:2; the specific surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com