Fluosilicic acid concentration method and device

A technology of fluosilicic acid and concentration tower, which is applied in the direction of fluosilicic acid and silicon halide compounds, which can solve the problems of high impurity content and low concentration of fluosilicic acid, and achieve the effect of meeting product performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, so that those skilled in the art of the present invention can easily implement the present invention.

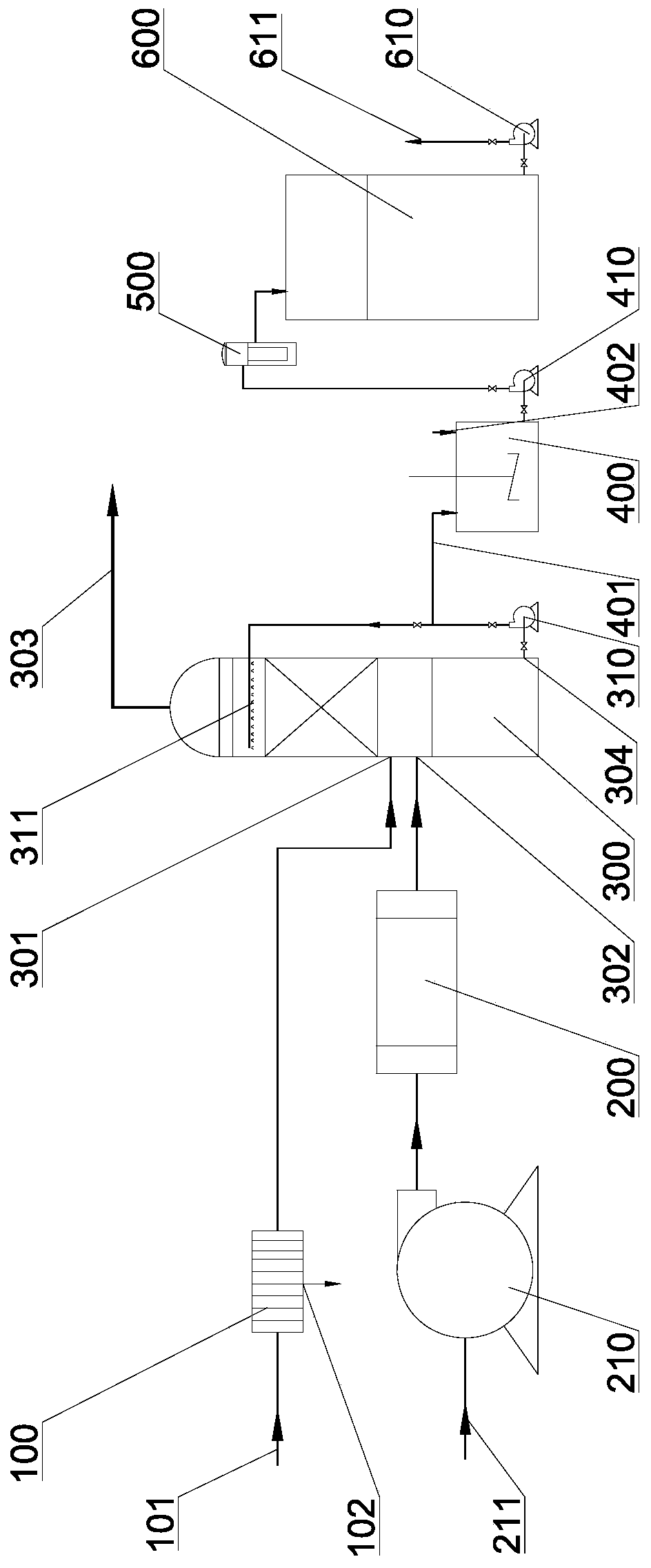

[0020] like figure 1 As shown, the present invention provides a device for concentrating fluosilicic acid, which is used to concentrate low-concentration fluosilicic acid by-products of phosphate fertilizers to obtain high-concentration fluosilicic acid products. The present invention includes sequentially connected concentrating equipment, purification equipment and storage equipment, the front end of the concentration equipment is also connected to the separation equipment 100 and the heating equipment.

[0021] Separation equipment 100 is used to pretreat and separate silica gel with low-concentration fluosilicic acid. The low-concentration fluosilicic acid inlet 101 is fed with low-concentration fluosilicic acid. The separation of silica gel in low-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com