Method for preparing carbon dioxide reduction photocatalyst by utilizing hyperaccumulators

A technology for hyper-accumulation of plants and carbon dioxide is applied in the field of preparing carbon dioxide reduction photocatalysts, which can solve the problems of inability to use photocatalytic reduction reaction and complex process, and achieve the effects of improved performance, simple preparation process and effective reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1 Preparation of Hydrothermal Carbon / Rare Earth Composite Materials Using Osmanthus osmanthus

[0045] The hydrothermal carbon / copper composite photocatalyst was prepared by utilizing the copper-enriched biomass of Osmanthus fragrans. Weighed 3 g of Osmanthus frondosa, which had been crushed and desanded, into 20 mL of distilled water, and stirred it magnetically for 5 minutes at room temperature, and then added In a stainless steel hydrothermal reaction kettle lined with tetrafluoroethylene, the reaction temperature is 180°C, and the heat preservation is 16h, and the obtained black product is obtained; the obtained product is centrifuged at 2000rpm for 30min, and washed several times alternately with distilled water and methanol; finally, the sample is placed in the Dry in a vacuum oven at 80°C for 24 hours, and take it out to obtain a hydrothermal carbon / rare earth composite material.

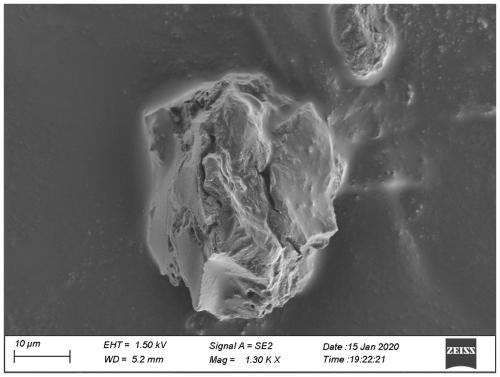

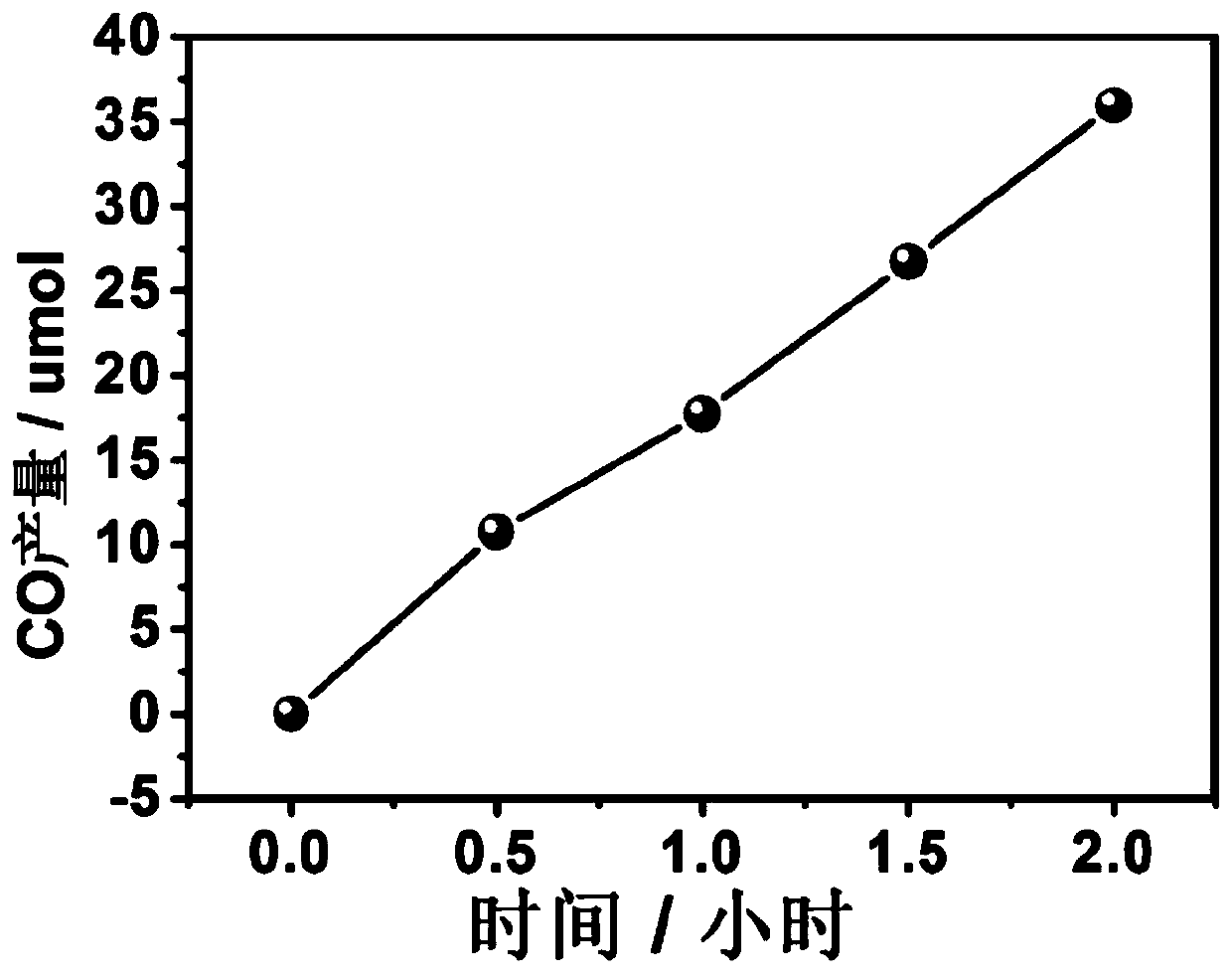

[0046] Pictures of mangosteen figure 1 As shown, the photo of the hydrother...

Embodiment 2

[0047] Example 2 Preparation of Hydrothermal Carbon / Copper Composite Material by Using Herba Cinnamomi

[0048] The hydrothermal carbon / copper composite photocatalyst was prepared by using Cystia haizhou, a copper-enriched biomass. Weigh 200g of the crushed and desand-removed Herba Cinnamon in 2000mL of distilled water, stir it magnetically for 10 minutes at room temperature, and then add it to a polytetrafluoroethylene-lined stainless steel hydrothermal reaction kettle with a reaction temperature of 250°C. Insulate for 10 hours to obtain a black product; centrifuge the obtained product at 5000rpm for 20 minutes, alternately wash several times with distilled water and methanol; finally dry the sample in a vacuum oven at 90°C for 12 hours, and take it out to obtain a hydrothermal carbon / copper composite material .

Embodiment 3

[0049] Example 3 Preparation of Hydrothermal Carbon / Nickel Composite Materials Using Phyllophyllum Beads

[0050] Preparation of hydrothermal carbon / nickel composite photocatalysts from Phyllophyllum biomass. Weigh 0.2g of the crushed and desand-removed Herba Cinnamon in 10mL of distilled water, stir it magnetically for 5 minutes at room temperature, and then add it to a polytetrafluoroethylene-lined stainless steel hydrothermal reaction kettle with a reaction temperature of 120°C , heat preservation for 50h, the obtained black product; the obtained product was centrifuged at 10000rpm for 10min, washed several times alternately with distilled water and methanol; finally, the sample was dried in a vacuum oven at 70°C for 36h, and the hydrothermal carbon / nickel composite was obtained after taking it out Material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com