Carbon aerogel prepared from superfine nano aerogel obtained through TEMPO (2,2,6,6-tetramethylpiperidinooxy) oxidation and preparation method of carbon aerogel

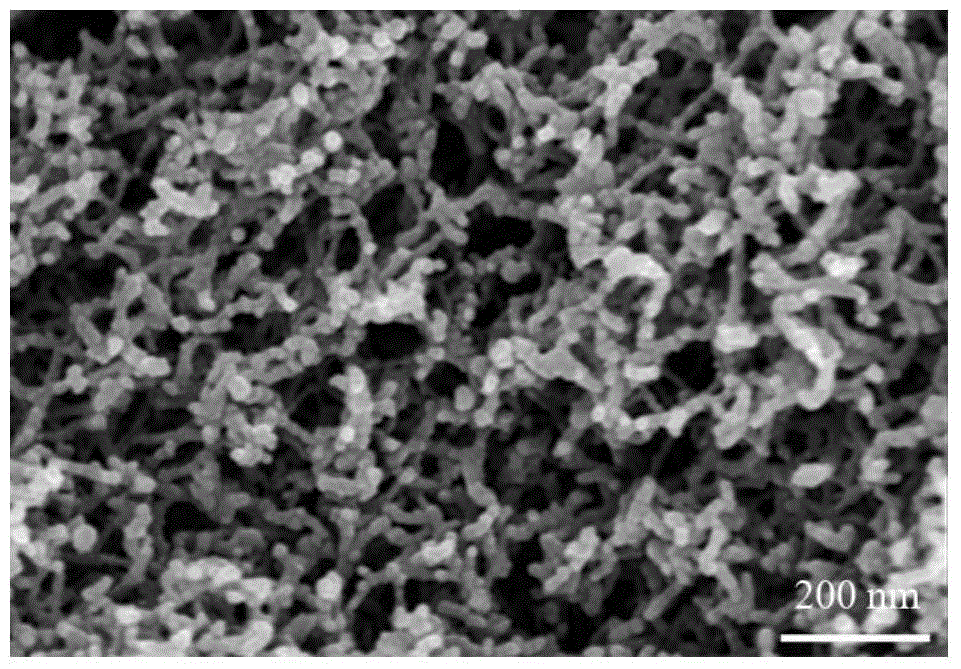

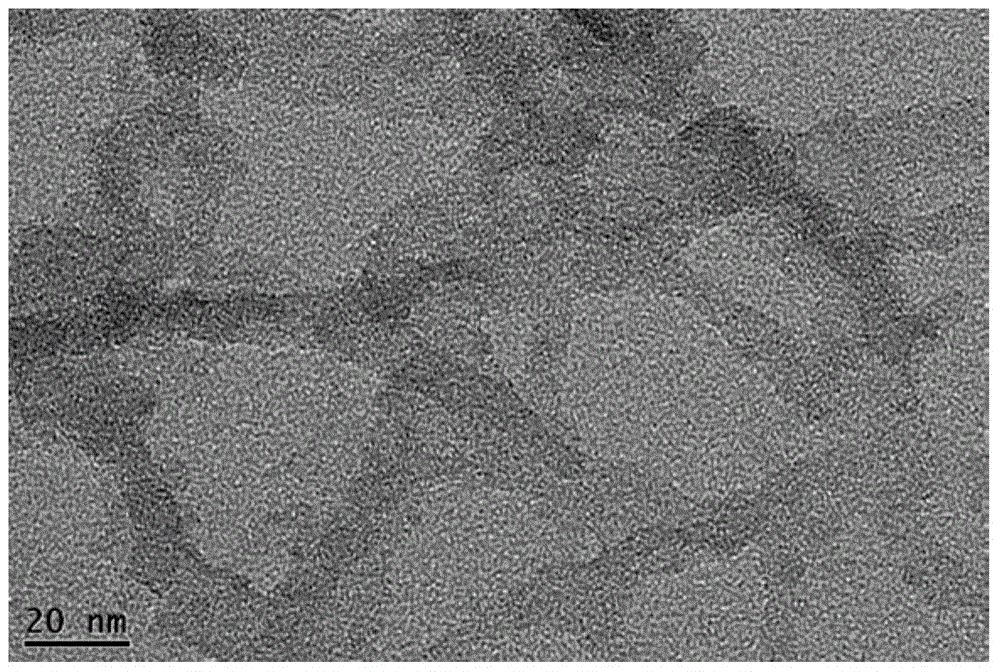

A carbon aerogel, ultra-fine nano technology, applied in the field of carbon aerogel and its preparation, can solve the problems of carbon aerogel specific surface area, low porosity, non-uniform structure, etc., and achieves a simple, safe and controllable preparation process. , The effect of uniform structure and rich products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. Extract the bamboo pulp with phenylethanol at a ratio of 1:2 to remove some organic matter, then use glacial acetic acid to adjust the pH to 4-5 and add 1wt% NaClO 2 Heating at 75°C for 1h and bleaching; the bleached bamboo powder is prepared as a 1wt% dispersion by a high-pressure homogenization method to obtain a 1wt% coarse cellulose dispersion;

[0041]2. Add phosphate buffer solution to the above dispersion liquid, adjust the pH of the dispersion liquid to 6.8 and stir on a magnetic stirrer for 5-10 minutes to better disperse the cellulose;

[0042] 3. Then add TEMPO and NaClO, disperse evenly and then add NaClO 2 , TEMPO:NaClO:NaClO 2 1:1:100 (molar ratio), quickly seal the container and heat it to 65°C for 2 hours. After the reaction, add a certain amount of ethanol to terminate the reaction. The amount of ethanol added is ethanol:NaClO 2 =1:500 (molar ratio);

[0043] 4. Repeatedly rinse the obtained dispersion with deionized water until it becomes neutral...

Embodiment 2

[0047] 1. Buy bleached bamboo pulp on the market, crush it through an 80-mesh sieve, prepare a 1wt% dispersion, and store it at 4°C

[0048] 2. Take 400ml of the above dispersion, stir it evenly, add 300ml of phosphate buffer solution, and adjust the pH of the dispersion to 6.8.

[0049] 3. Then add TEMPO and NaClO, disperse evenly and then add NaClO 2 , TEMPO:NaClO:NaClO 2 The molar ratio is 1:13:100, and the container is quickly sealed and heated to 70°C for 1-2 hours. After the reaction, a certain amount of ethanol is added to terminate the reaction. The amount of ethanol added is ethanol: NaClO 2 =1:300 (molar ratio);

[0050] 4. Repeatedly rinse the obtained dispersion with deionized water until it becomes neutral, and then use an ultrasonic pulverizer (1500W) to sonicate the dispersion for 1 hour;

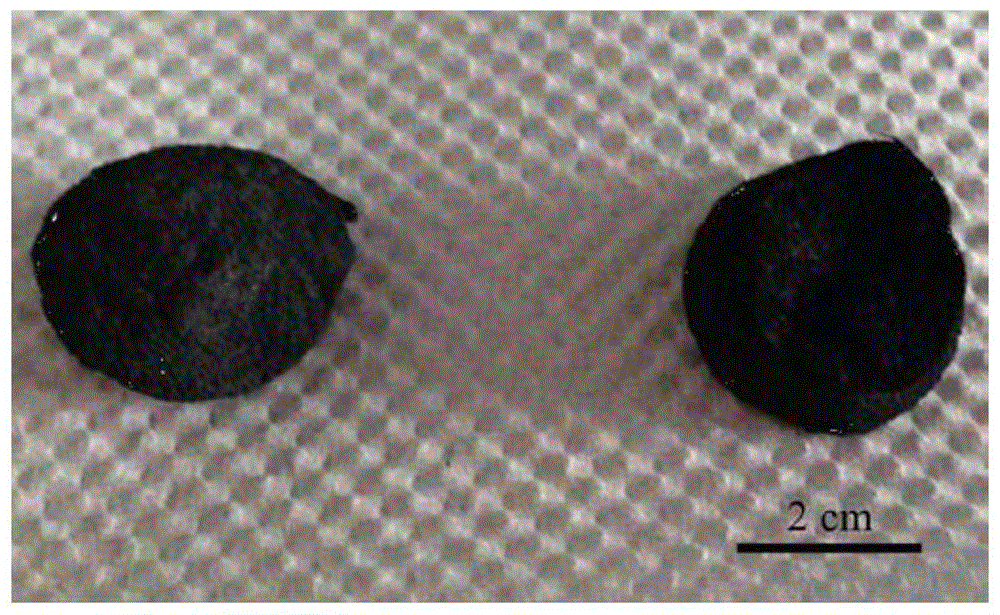

[0051] 5. Substitute the dispersion with tert-butanol to obtain a gel, freeze the obtained gel at -20°C for 4 hours, and obtain nanocellulose airgel after freeze-drying; ...

Embodiment 3

[0054] 1. Buy bleached bamboo pulp on the market, crush it through an 80-mesh sieve, prepare a 1wt% dispersion, and store it at 4°C

[0055] 2. Take 400ml of the above dispersion, stir it evenly, add 0.064g of TEMPO and 0.4g of NaBr, after the dispersion is uniform, add 2mol / LNaClO, use 0.5mol / LNaOH to control the pH of the dispersion at 10.2, react for 1h, then add 25ml of ethanol to terminate reaction;

[0056] 3. Repeatedly rinse the obtained dispersion with deionized water until it becomes neutral, and then use an ultrasonic pulverizer (1500W) to sonicate the dispersion for 2 hours;

[0057] 4. Replace the dispersion with tert-butanol to obtain a gel, freeze the obtained gel at -80°C for 4 hours, and obtain nanocellulose airgel after freeze-drying;

[0058] 5. Heat the nanocellulose airgel in a tube furnace Ar 2 Under protection, heat at 5°C / min to 800°C and hold for 1.5h, then rapidly cool down at 8°C / min to obtain carbon aerogels with better morphology.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com