Chemical alkali manufacture waste harness and high value utilization process

A waste and high-value technology, applied in the field of clean production process innovation in the chemical soda industry, can solve problems such as undetected and achieve remarkable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

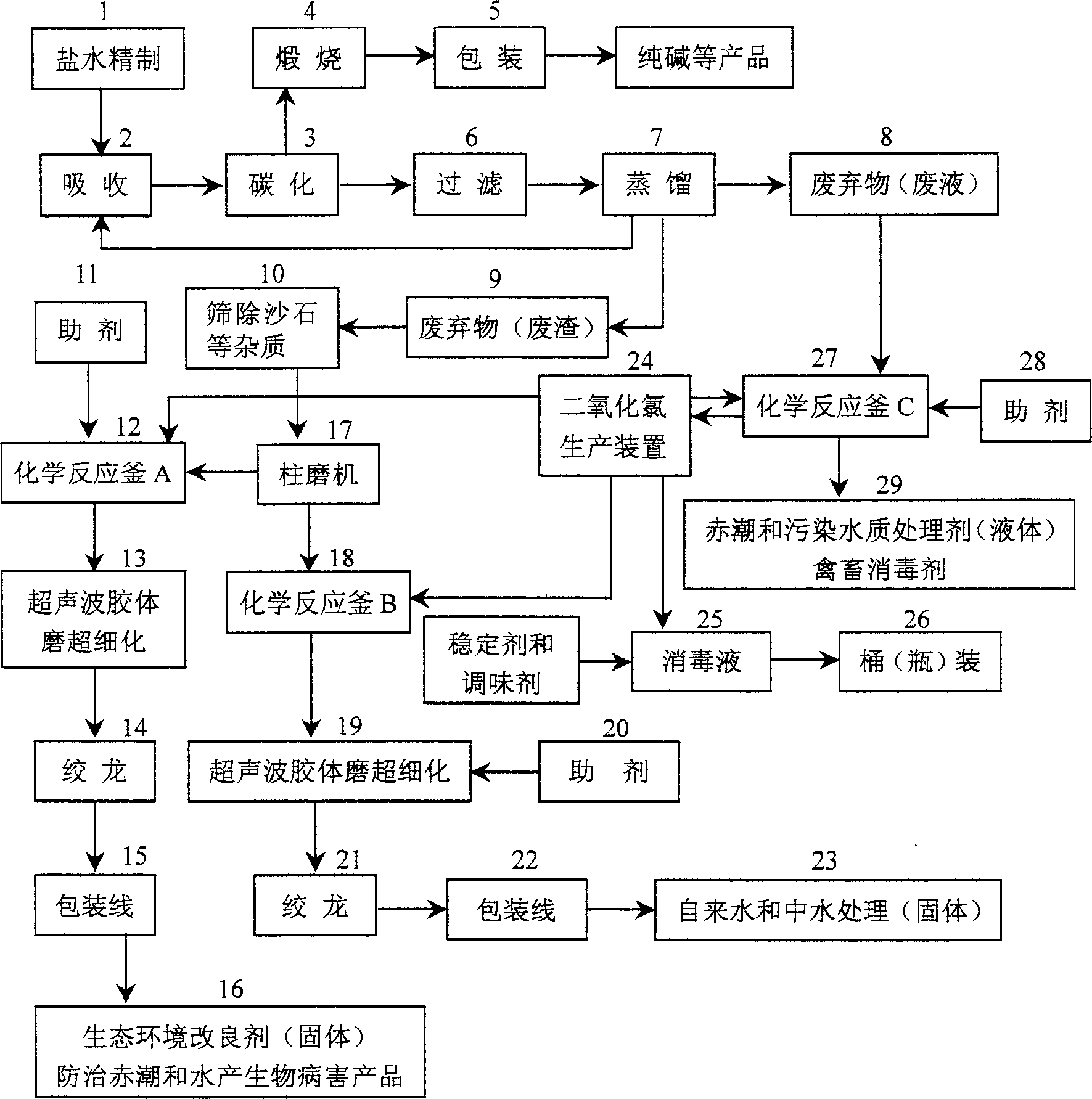

[0025] Such asfigure 1 The shown technological process, after step 7 is distilled, waste (alkali slag) is obtained, and impurities such as sand and stone are removed through step 10 with a vibrating sieve, and through step 17, coarsely ground with a column mill, in the chemical reaction kettle A, each Add 1 to 15 kg of chlorine dioxide, 5 to 65 kg of chlorate, 3 to 35 kg of chlorite, 15 to 75 kg of hypochlorite, and 15 to 75 kg of 5 to 80 kg, 1 to 15 kg of carbonate, and 1 to 5 hours of reaction time; superfine treatment by ultrasonic colloid mill in step 13, 99% of the obtained product has a particle size of 0.1 nm to 15 μm; and then packed. The products produced produce nano-sized particles in water bodies and have strong oxidizing ability. As ecological environment improvers and sewage treatment agents, products for preventing red tides and aquatic biological diseases are used at a concentration of 1-150ppm, of which: preventing red tides and freshwater The dosage of Huahua...

Embodiment 2

[0030] Such as figure 1 As shown in the process flow, after the alkali slag of the alkali industry waste is removed from impurities and column milled, in the chemical reaction kettle B, chlorine dioxide is produced by the above-mentioned chlorine dioxide production device, so that the alkali slag is combined with the chlorine dioxide in the chemical reaction kettle B. Chlorine oxide reacts directly, the weight percentage of chlorine dioxide is 1-11%, and then ultra-fine by ultrasonic colloid mill to obtain 99% of the product with a particle size of 0.1nm-15μm; it is packed in bags or barrels. The obtained product is used to directly purify domestic drinking water and urban reclaimed water with high hygienic standards. The water consumption is 3-85ppm. Its specific implementation is shown in Table 4. If the concentration of chlorine dioxide in the product exceeds 2%, the requirements for transportation and storage conditions are more complicated. Therefore, products with a c...

Embodiment 3

[0033] Such as figure 1 Shown technical process, according to step 7, waste (waste liquid) is obtained after distillation, in chemical reactor C, add the chlorine dioxide that is made by above-mentioned chlorine dioxide production device 24, make the concentration balance of chlorine dioxide, add Hydroxide (potassium hydroxide or sodium hydroxide), make its weight percentage be 1~3%, generate liquid product, wherein the concentration of chlorine dioxide is 1~3%, the concentration of calcium chloride is 23~25% %, the product is filled or bottled, and the concentration used is 1-150ppm, of which: 1-65ppm is used to prevent red tide and freshwater bloom; 1-65ppm is used to prevent and control fish and shrimp diseases; The amount of waste water is 15-150ppm. Its specific implementation is shown in Table 5.

[0034] serial number

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com