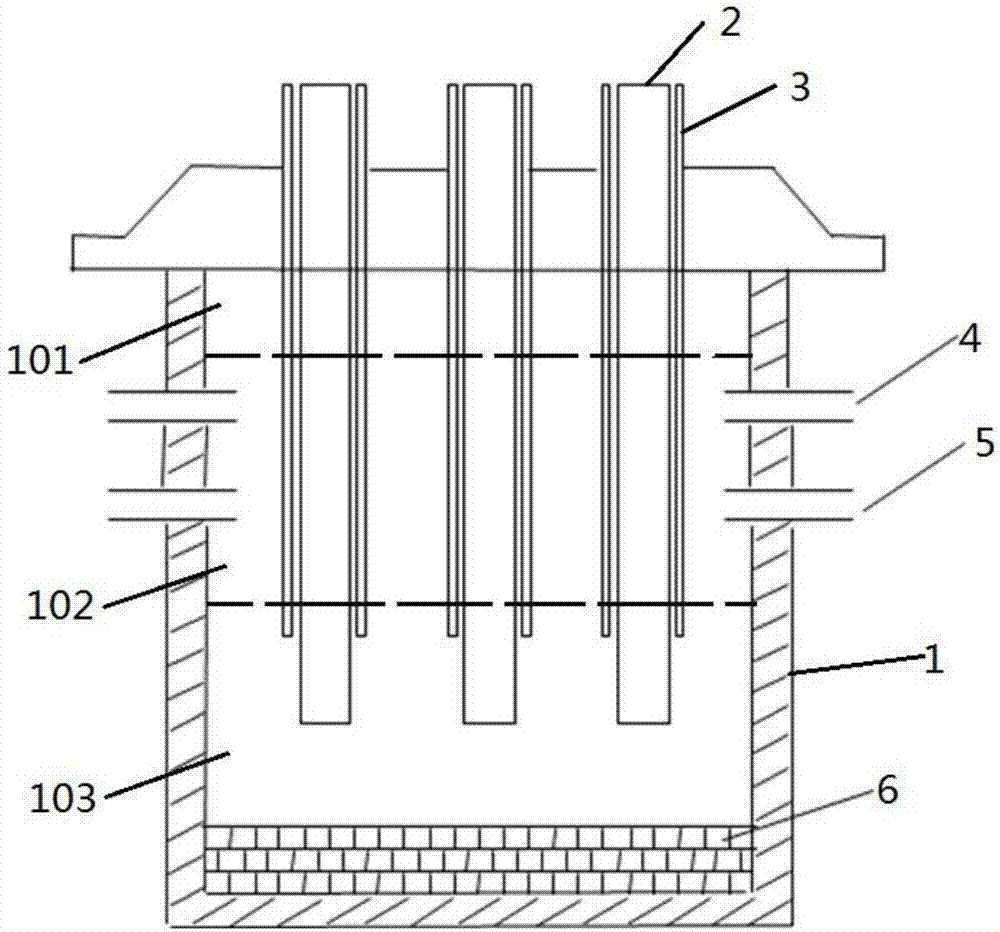

Calcium carbide furnace

A calcium carbide furnace and furnace body technology, applied in the directions of magnesium oxide, carbide, calcium carbide, etc., can solve the problems of difficulty in the furnace, sticky calcium carbide, affecting normal production, etc., so as to reduce the power consumption of calcium carbide production, increase the temperature of raw materials, avoid The effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. The spherical material is sent into the calcium carbide furnace through the feeding pipe, and the components of the spherical material are semi-coke and lime.

[0035] 2. Feed oxygen into the furnace through the oxygen-containing gas inlet.

[0036] 3. Heating the spherical material to about 2000°C, the carbon in the spherical material and the CO in the gas will reduce the magnesium oxide in it to generate calcium carbide and tail gas containing magnesium vapor; part of the carbon and oxygen in the spherical material will be incompletely combusted, Provide part of the energy for calcium carbide production.

[0037] 4. The tail gas containing magnesium vapor rises, and the temperature gradually decreases. In the thermosphere zone of 1400-1600 ° C, it is discharged from the calcium carbide furnace through the tail gas outlet.

[0038] 5. The tail gas containing magnesium vapor enters the flue from the tail gas outlet, and when the temperature drops below 1200°C in the...

Embodiment 2

[0041] 1. The spherical material is sent into the calcium carbide furnace through the feeding pipe, and the components of the spherical material are biomass and lime.

[0042] 2. Feed oxygen into the furnace through the oxygen-containing gas inlet.

[0043] 3. Heating the spherical material to about 2100°C, the carbon in the spherical material and the CO in the gas will reduce the magnesium oxide in it to generate calcium carbide and tail gas containing magnesium vapor; part of the carbon and oxygen in the spherical material will be incompletely combusted, Provide part of the energy for calcium carbide production.

[0044] 4. The tail gas containing magnesium vapor rises, and the temperature gradually decreases. In the thermosphere zone of 1400-1600 ° C, it is discharged from the calcium carbide furnace through the tail gas outlet.

[0045] 5. The tail gas containing magnesium vapor enters the flue from the tail gas outlet, and when the temperature drops below 1200°C in the flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com