Biomass-based nitrogen-doped porous carbon material, and preparation method and application thereof

A nitrogen-doped porous carbon and biomass material technology, applied in chemical instruments and methods, alkali metal compounds, other chemical processes, etc., can solve the problems of insufficiently developed pore structure of carbon materials, harsh reaction conditions, and complicated operation steps. Achieve the effect of overcoming low carbon dioxide adsorption capacity, uniform distribution and abundant resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the nitrogen-doped porous carbon material according to the present invention is a one-step "foaming method". The porous nitrogen-doped carbon material synthesized by this method not only has a large specific surface area, pore volume, and abundant macropores / mesopores / Microporous multi-level pore structure, and the basic position of the porous material is increased, so that the porous nitrogen-containing material becomes an excellent carbon dioxide adsorption material, with high carbon dioxide adsorption capacity and good recycling performance.

[0029] In the preparation method according to the present invention, the activator plays an important role in the formation process of the nitrogen-doped porous carbon material, and it has the function of a pore-forming agent. Relative to the weight of the biomass material, when the amount of the activator is less than 0.1 times, it will affect the formation of the porous structure of the material, an...

Embodiment 1

[0039]Cut 1 kg of cleaned sweet potato leaves into pieces, heat them in an oven at 70° C. to dry, and grind the solids into powders. Take 5g powder and 5g NaHCO 3 Add 20mL of water and heat to dryness at 100°C. Afterwards, the obtained dry solid was calcined in a tube furnace in a nitrogen gas atmosphere, and kept at 600° C. for 2 hours. After the tube furnace dropped to room temperature, the samples were taken out, washed several times with 1% hydrochloric acid and water, and dried at 100° C. to obtain nitrogen-doped porous carbon materials.

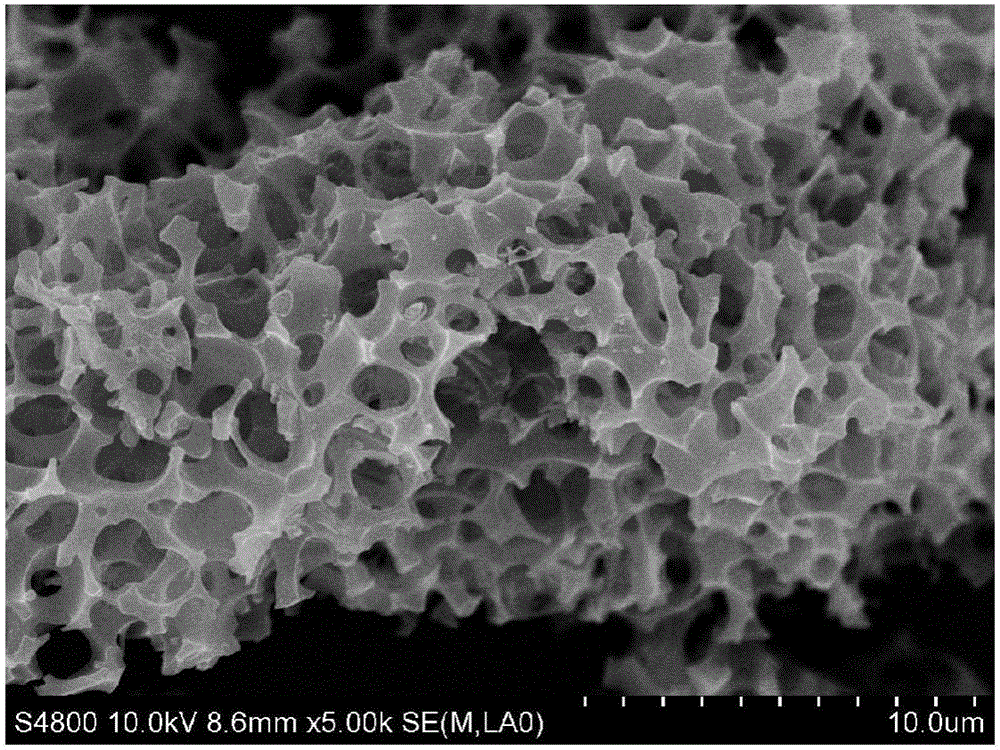

[0040] figure 1 This is the SEM photo of the nitrogen-doped porous carbon material prepared according to this example. It can be seen from the photo that the nitrogen-doped porous carbon material prepared according to this example has an obvious three-dimensional porous network structure, and the pore structure is remarkable. Elemental analysis results showed that the nitrogen content was 3.2 at%. BET test shows that its specific su...

Embodiment 2

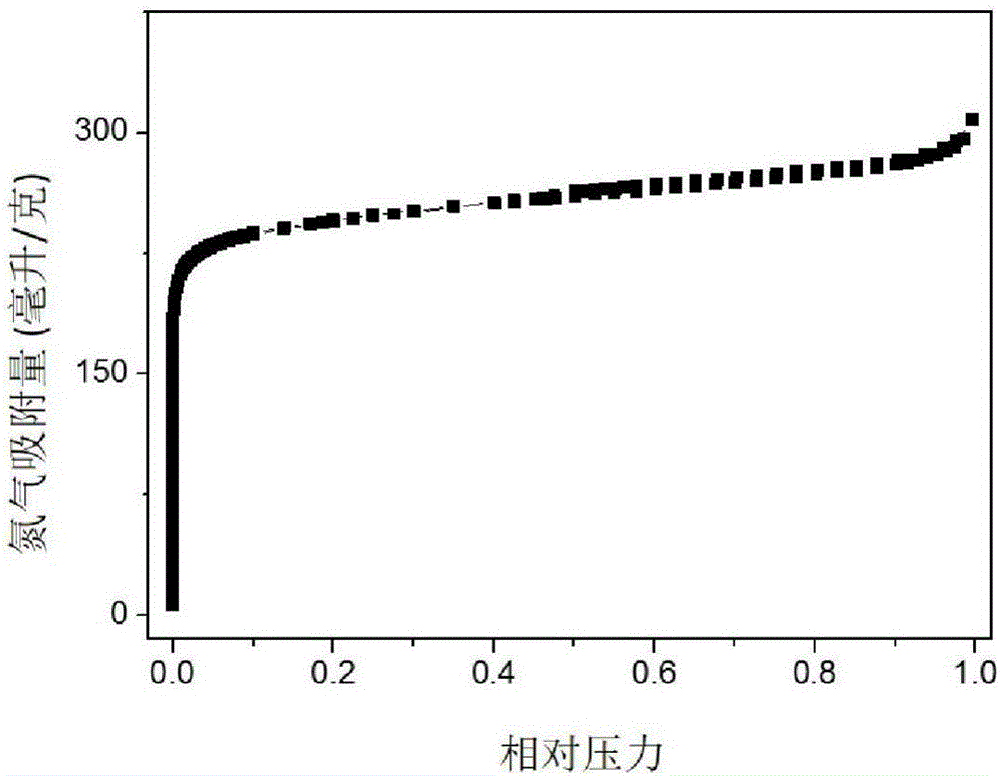

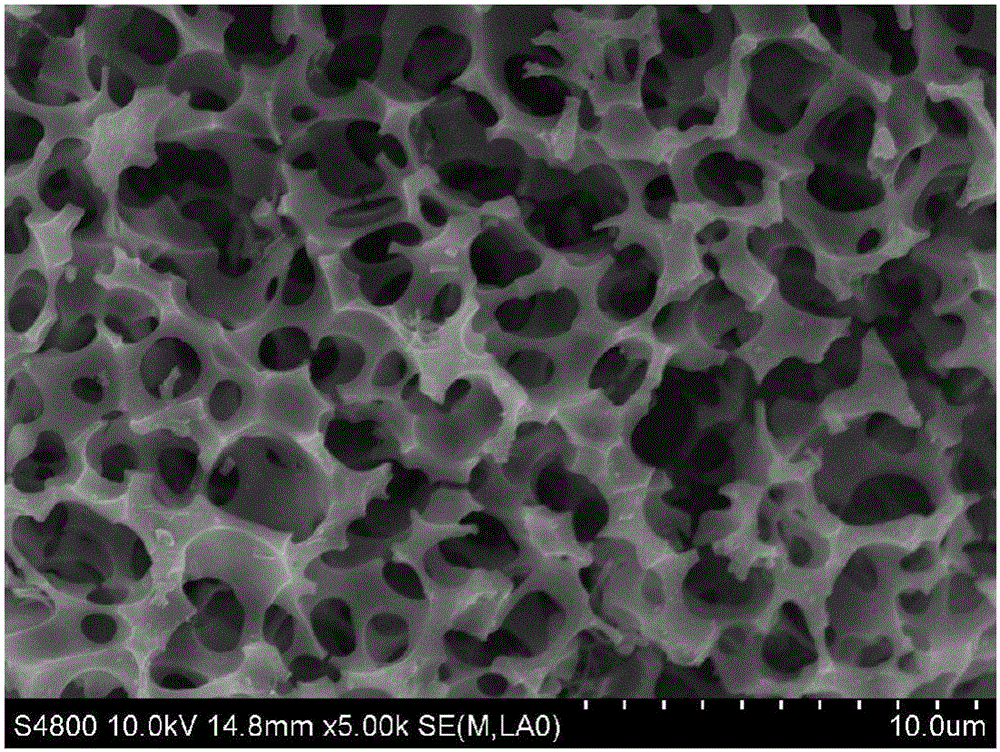

[0042] Cut 1 kg of cleaned asparagus into pieces, heat to dry in an oven at 70° C., and grind the solid into powder. Take 5g powder and 5g KHCO 3 Add 20mL of water and heat to dryness at 100°C. Afterwards, the obtained dry solid was calcined in a tube furnace in a nitrogen gas atmosphere, and kept at 600° C. for 2 hours. After the tube furnace dropped to room temperature, the samples were taken out, washed several times with 1% hydrochloric acid and water, and dried at 100° C. to obtain nitrogen-doped porous carbon materials. The elemental analysis results show that the nitrogen content of the material is 3.6at%, and the BET test results are as follows figure 2 As shown, the specific surface area is about 963m 2 / g, the pore volume is 0.48cm 3 / g. like image 3 As shown in the SEM photos in , the material has a three-dimensional porous structure and contains a large number of micropores and a certain amount of mesopores and macropores.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com