Method of preparing room temperature ferromagnetism Zn(1-X)Mn(X)O diluted magnetic semiconductor nano-line

A room temperature ferromagnetic and nanowire technology, applied in chemical instruments and methods, from chemical reactive gases, crystal growth and other directions, to achieve the effects of low preparation temperature, controllable reaction conditions and high crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

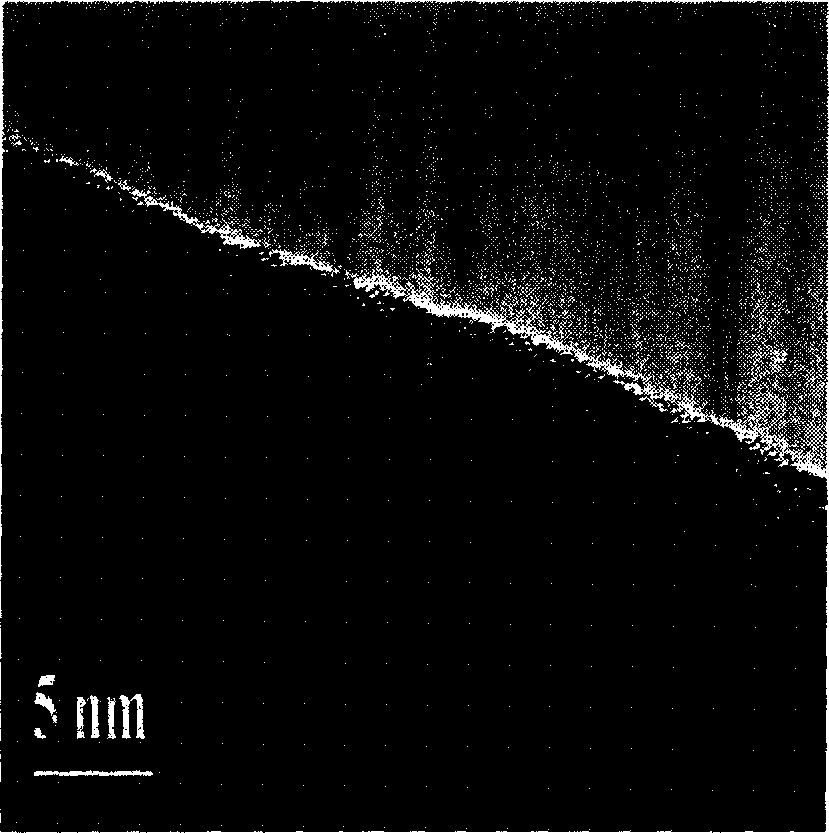

[0021] The silicon wafer was cleaned with hydrochloric acid, rinsed with deionized water, then cleaned with acetone, and finally rinsed with deionized water. Zn powder and MnCl 2 The powder is placed adjacent to the middle of the quartz boat, and the silicon wafer is covered at the junction of the two evaporation sources, and the vertical distance from the evaporation source is 7mm. Put the quartz boat into the tube furnace, the inlet of the system can be fed with gas, and the gas is introduced into the water with a rubber tube at the outlet. The system was fed with 300 ml / min of argon, and after 8 minutes, the flow rate of argon was changed to 30 ml / min. Heat the tube furnace to 810°C, keep the system pressure at atmospheric pressure, keep it warm for 120min and then cool it down to room temperature naturally to get Zn 1-x mn x O(x=10%) nanowires. The diameter of the nanowire is 30-100 nm, and the length is 7-18 μm.

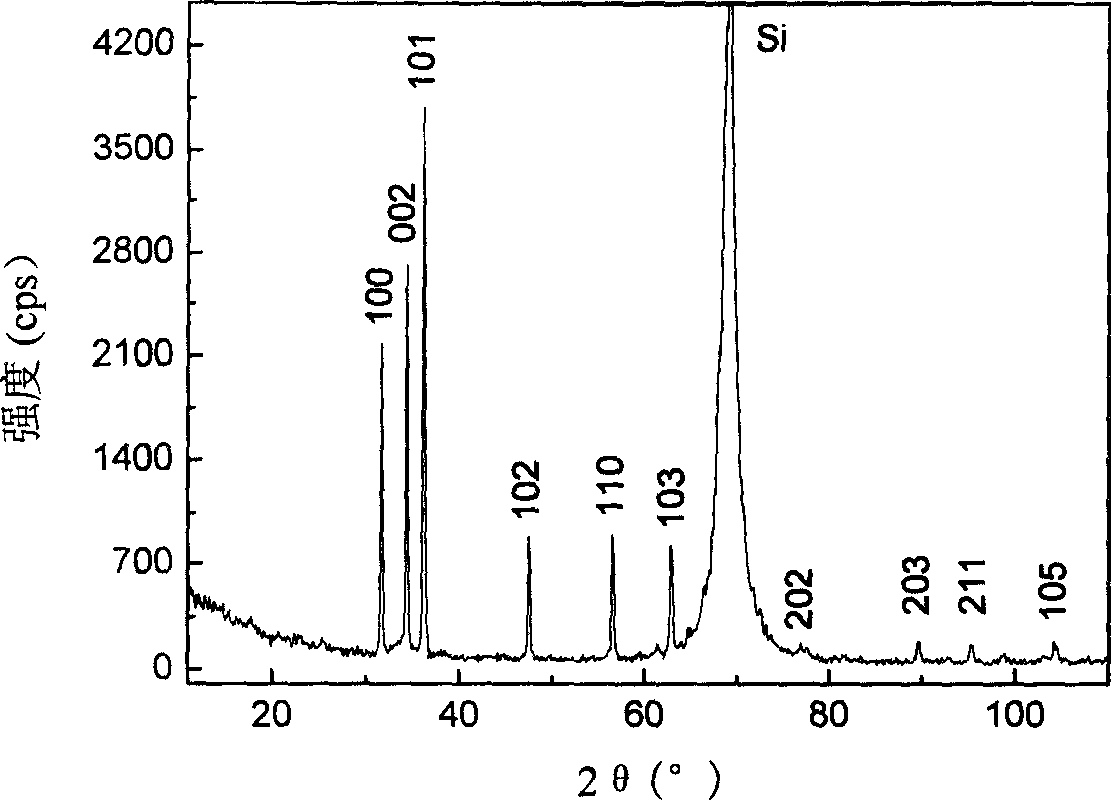

[0022] The structure of the product was analyzed by a...

Embodiment 2

[0024] The silicon wafer was cleaned with hydrochloric acid, rinsed with deionized water, then cleaned with acetone, and finally rinsed with deionized water. Zn powder and MnCl 2 The powder is placed adjacent to the middle of the quartz boat, and the silicon wafer is covered at the junction of the two evaporation sources, and the vertical distance from the evaporation source is 7mm. Put the quartz boat into the tube furnace, the inlet of the system can be fed with gas, and the gas is introduced into the water with a rubber tube at the outlet. The system is fed with 400 ml / min of argon, and after 5 minutes, the flow of argon is changed to 50 ml / min. Heat the tube furnace to 830°C, maintain the system pressure at atmospheric pressure, keep it warm for 150 minutes, and then cool it down to room temperature naturally to obtain Zn 1-x mn x O(x=20%) nanowires. The diameter of the nanowire is 60-150 nm, and the length is 10-22 μm.

Embodiment 3

[0026] The silicon wafer was cleaned with hydrochloric acid, rinsed with deionized water, then cleaned with acetone, and finally rinsed with deionized water. Zn powder and MnCl 2The powder is placed adjacent to the middle of the quartz boat, and the silicon wafer is covered at the junction of the two evaporation sources, and the vertical distance from the evaporation source is 8mm. Put the quartz boat into the tube furnace, the inlet of the system can be fed with gas, and the gas is introduced into the water with a rubber tube at the outlet. The system was fed with 340 ml / min of argon, and after 7 minutes, the argon flow rate was changed to 40 ml / min. Heat the tube furnace to 805°C, keep the system pressure at atmospheric pressure, keep it warm for 140min, and then cool it down to room temperature naturally to get Zn 1-x mn x O(x=3.5%) nanowires. The diameter of the nanowire is 30-80 nm, and the length is 5-14 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com