Oxidizing tank

An oxidation tank and tank body technology, applied in the field of oxidation tanks, can solve the problems of low oxidation efficiency, uneven oxidation, high energy consumption, etc., and achieve the effects of easy maintenance, uniform oxidation, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

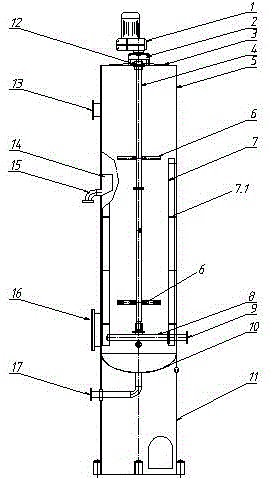

[0011] Embodiment 1: An oxidation tank includes a vertical cylindrical tank body 5, the bottom of the tank body 5 is installed on a skirt 11, the bottom of the skirt 11 is reliably connected with the ground embedded screw, and the top of the tank 5 is sealed The cover plate 3 is sealed, and the mixer reducer 1 is fixed on the top of the tank 5 through the base 2. The mixing shaft 4 in the tank 5 is connected to the mixer reducer 1 through the coupling 12, and the mixing shaft 4 is provided with multiple groups Staggered blades 6, the upper part of the tank body 5 is provided with an exhaust port 13 and an overflow port 15, the bottom of the tank body 5 is provided with a manhole 16, an air inlet 9, and a sewage inlet 17, and the inner bottom of the tank body 5 is provided with an air pipe 8 , The overflow port 15 in the tank body 5 is provided with a circle of water outlet weir grooves 14, and the inner wall of the tank body 5 is provided with a strip baffle plate 7, which is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com