Making process of antiwear nonstick cooker

A production method and high wear-resistant technology, which are applied in the production of non-stick cookware and the field of cookware production, can solve the problems of poor wear resistance and non-stick performance of cookware, and achieve long service life and excellent non-stick performance. , the effect of easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

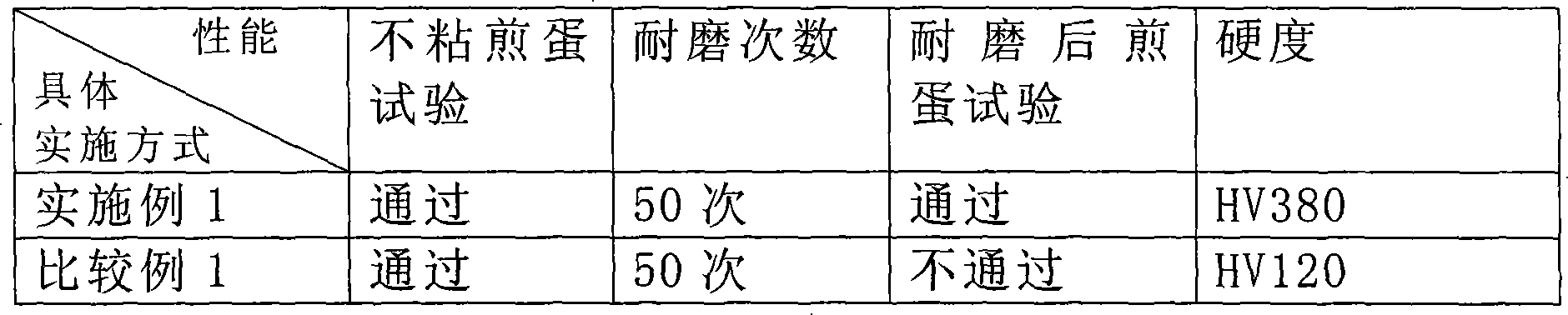

[0025] Embodiment 1: Making a highly wear-resistant non-stick pan

[0026] A. Molding: choose an aluminum alloy plate with a thickness of 3mm and process it into a pot semi-finished product according to the shape of the pot, and then intrude the pot semi-finished product into a surface degreasing solution with a temperature of 80°C for surface degreasing treatment for 3 minutes; the surface The ratio of degreasing solution is: NaOH: 5g / L; NaOH: 5g / L; 2 CO 3 : 25g / L; Na 3 PO 4 12H 2 O: 10g / L; the rest is water.

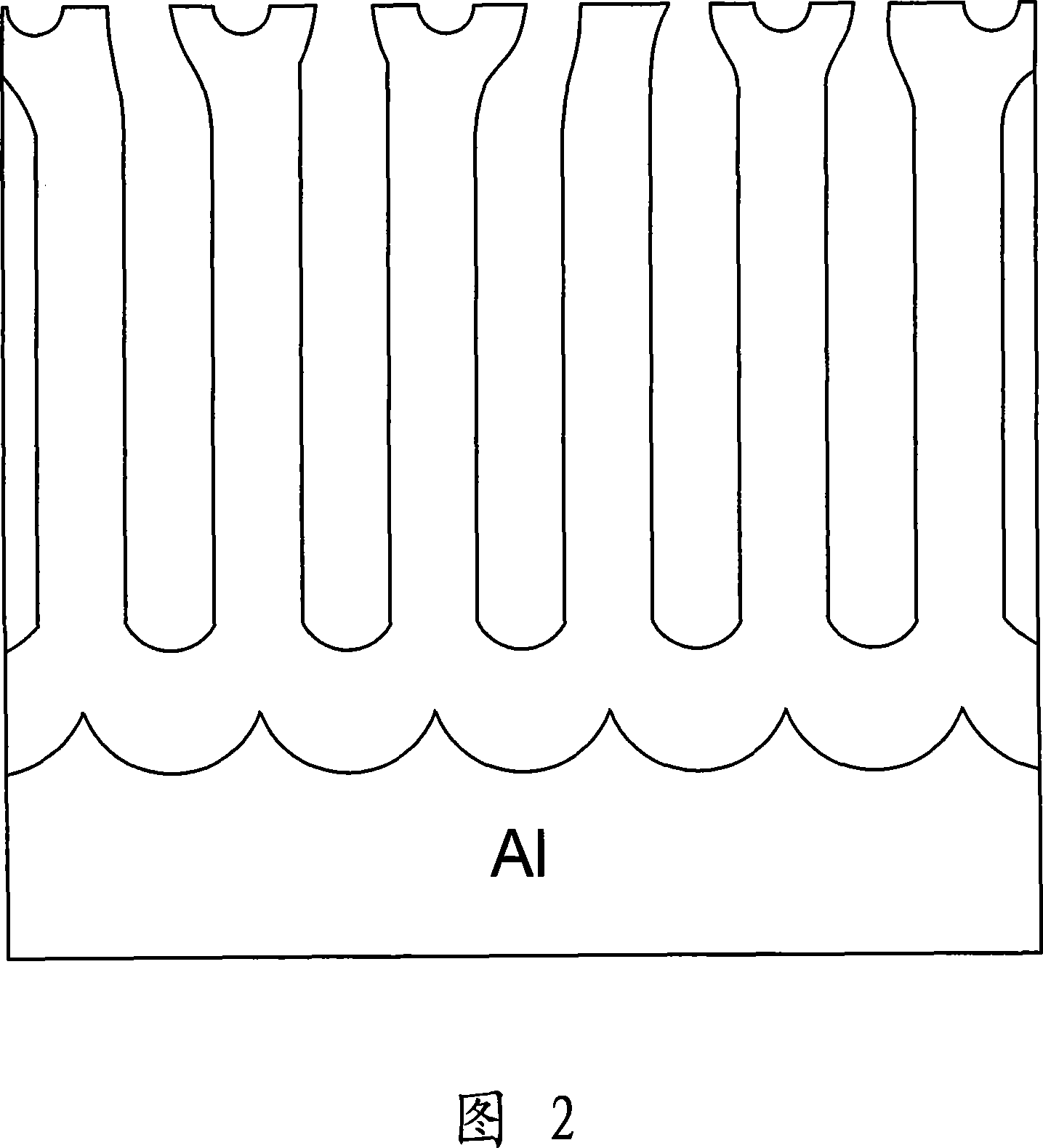

[0027] B. Anodizing: put the semi-finished product of the pot after the surface degreasing treatment into the anode power supply with a concentration of 180g / L sulfuric acid solution, at a current density of 2A / dm 2 Under the condition of direct current, the anodic oxidation treatment is carried out at a temperature of 5° C. for 90 minutes to form an oxide film with a pore thickness of 25-150 μm.

[0028] C. Permeation: Place the above semi-finished product of th...

Embodiment 2

[0036] Example 2: Making a highly wear-resistant non-stick disk

[0037] A. Molding: Select an aluminum plate with a thickness of 4mm to be processed into a disc semi-finished product according to the shape of the disc, and then immerse the disc semi-finished product into a surface degreasing solution with a temperature of 50°C for surface degreasing treatment for 5 minutes; the surface degreasing The ratio of the solution is: NaOH: 6g / L; NaOH: 6g / L; 2 CO 3 : 20g / L; Na 3 PO 4 12H 2 O: 15g / L; the rest is water.

[0038] B. Anodizing: Put the above semi-finished discs after the surface degreasing treatment into the anode of the power supply of sulfuric acid solution with a concentration of 180g / L, at a current density of 3A / dm 2 Under the condition of DC current, the anodic oxidation treatment is carried out for 70 minutes at a temperature of 0° C. to form an oxide film with a pore thickness of 25-150 μm.

[0039] C. Penetration: Place the above semi-finished anodized disc...

Embodiment 3

[0041] Example 3: Making a highly wear-resistant non-stick basin

[0042] A. Molding: Use aluminum sheet with a thickness of 3.5mm to process and shape it into a semi-finished basin, and then perform surface degreasing treatment on the semi-finished basin; then immerse the semi-finished basin in a surface degreasing solution at a temperature of 90°C for surface degreasing treatment for 1 minute ; The proportioning of the surface degreasing solution is: NaOH: 5g / L; NaOH: 5g / L; 2 CO 3 : 22g / L; Na 3 PO 4 12H 2 O: 12g / L; the rest is water.

[0043] B. Anodizing: Put the above semi-finished pots after the surface degreasing treatment into the anode with a concentration of 220g / L sulfuric acid solution power supply, at a current density of 4A / dm 2 A direct current power supply is used to perform anodic oxidation treatment at a temperature of -10°C for 50 minutes to form an oxide film with a pore thickness of 25-150 μm.

[0044] C. Penetration: Place the semi-finished product o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com