Preparation method for nitrogen-doped anatase titanium dioxide

An anatase type, titanium dioxide technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of complex experimental process, low doping efficiency, cumbersome operation, etc., and achieve slowdown rate , increase the content of nitrogen, prevent the effect of recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

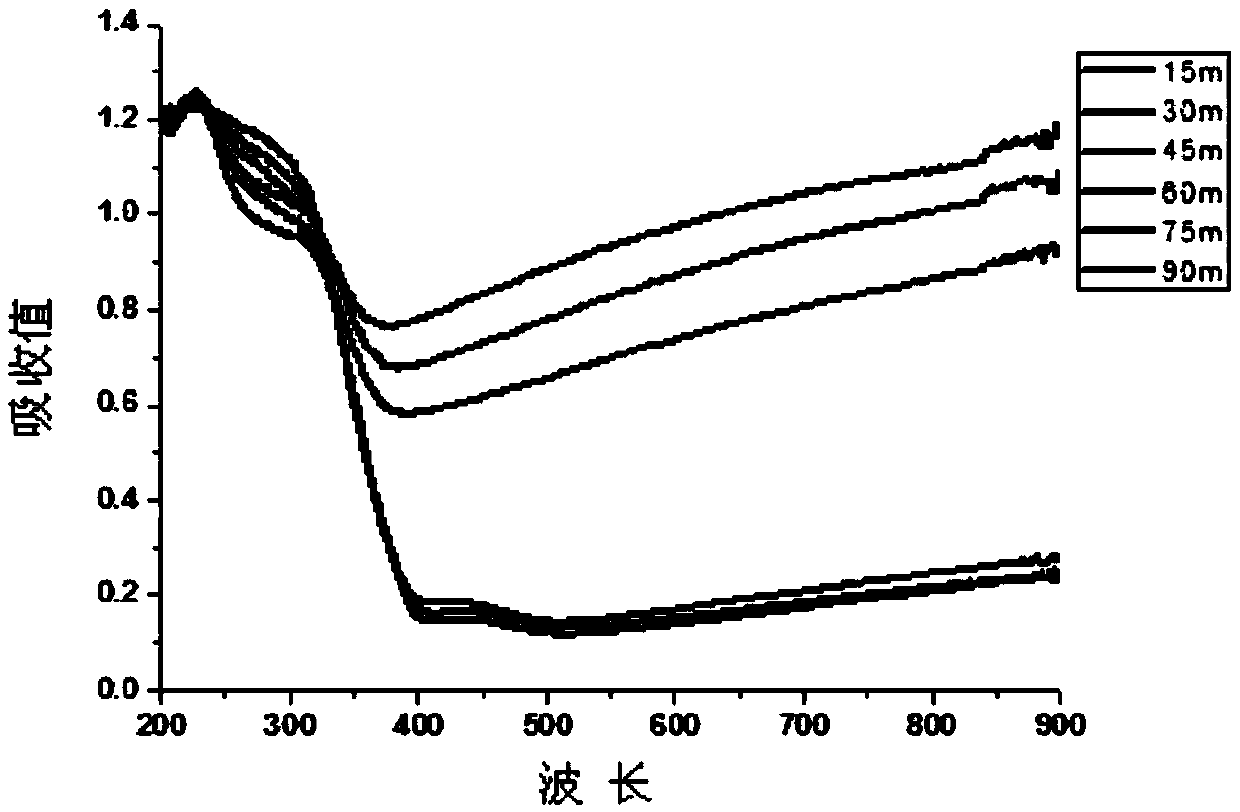

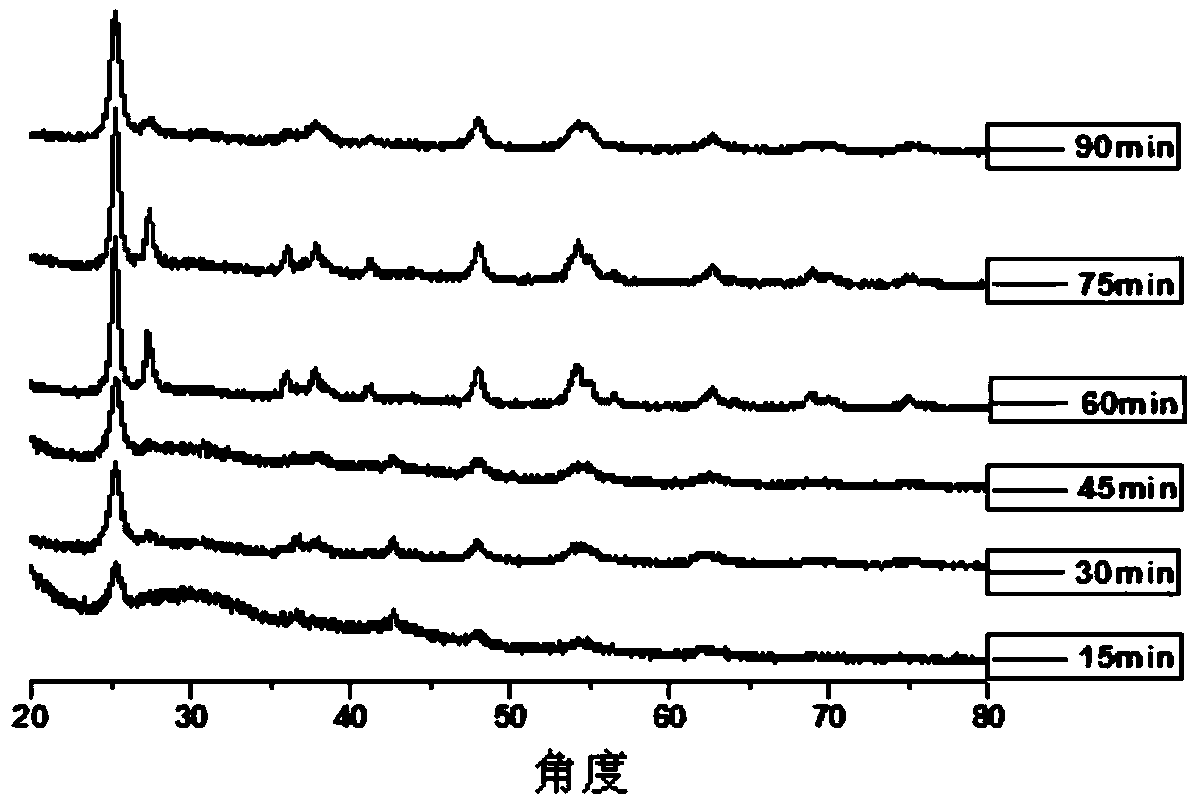

[0036] (1). Weigh 7 parts of titanium nitride with an average particle diameter of 20nm, place them in a muffle furnace, and calcinate at a constant temperature of 380°C for 30 minutes, and then lower to room temperature to obtain sample 1 and test sample 1. by figure 1 It is known that the anatase-type titanium dioxide peak held at a temperature of 380°C for 30 minutes and retains part of titanium nitride, which still has a high absorption of visible light.

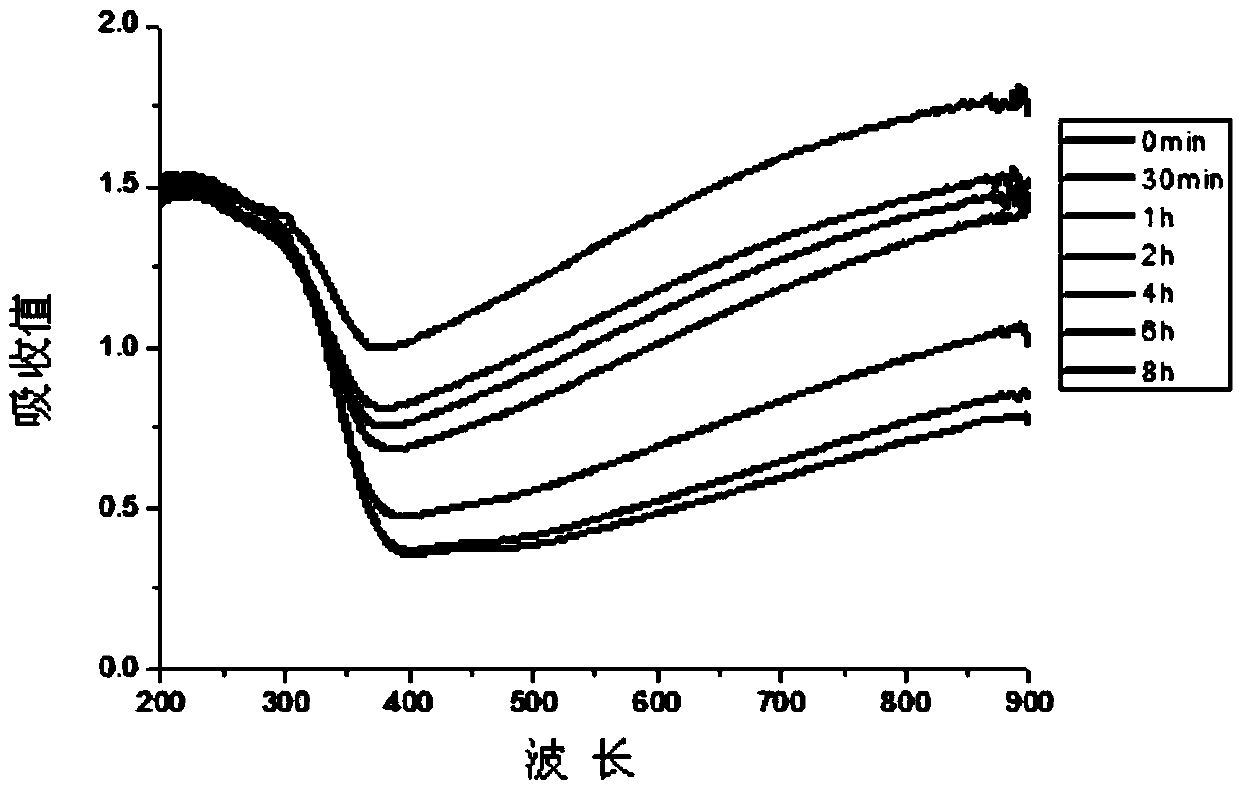

[0037] (2). Place the above sample 1 in a muffle furnace, calcinate at a constant temperature of 350°C for 1 hour, then cool to room temperature, take the sample out of the muffle furnace, and obtain sample 2, which is a nitrogen-doped anatase type Titanium dioxide material, made of image 3 It is known that the test sample 2 has not formed a 400nm visible light absorption platform after the second oxidation and calcination for 1 hour. by Figure 4 It is known that sample 2 still contains titanium nitride after being kept a...

Embodiment 2

[0039] (1). Weigh 8 parts of titanium nitride with an average particle diameter of 50nm, place them in a muffle furnace, and calcinate at a constant temperature of 420°C for 30 minutes, and then lower to room temperature to obtain sample 1 and test sample 1.

[0040] (2). Put the above sample 1 in a muffle furnace, calcined at a constant temperature of 350℃ for 2h, then lower to room temperature, take the sample out of the muffle furnace, and obtain sample 3, which is a nitrogen-doped anatase type Titanium dioxide material, made of image 3 It is known that the test sample 3 has not formed a 500nm visible light absorption platform after the second oxidation and calcination for 2 hours. by Figure 4 It is known that sample 3 has almost no titanium nitride after being kept at a temperature of 350°C for 2 hours.

Embodiment 3

[0042] (1). Weigh 8.5 parts of titanium nitride with an average particle size of 40nm, place it in a muffle furnace, reduce to room temperature, and calcine at a constant temperature of 395°C for 30 minutes to obtain sample 1 and test sample 1.

[0043] (2). Place the above sample 1 in a muffle furnace and calcinate at a constant temperature of 350°C for 4 hours. Take the sample out of the muffle furnace and cool to room temperature to obtain sample 4, which is nitrogen-doped anatase titanium dioxide. Material by image 3 It is known that the test sample 4 has formed a 450nm visible light absorption platform after the second oxidation and calcination for 4 hours. by Figure 4 It is known that there is no titanium nitride peak in sample 4 after a constant temperature of 350°C for 4 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com