Method for distributing intake airflow and exhaust airflow of coal mine methane device

An airflow distribution and coal mine technology, which is applied in safety devices, mine/tunnel ventilation, gas discharge, etc., can solve the problems of increased wind power consumption, increased wind resistance, and uneven distribution of oxidation devices, so as to reduce gas interference and ensure Temperature field, ensuring uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

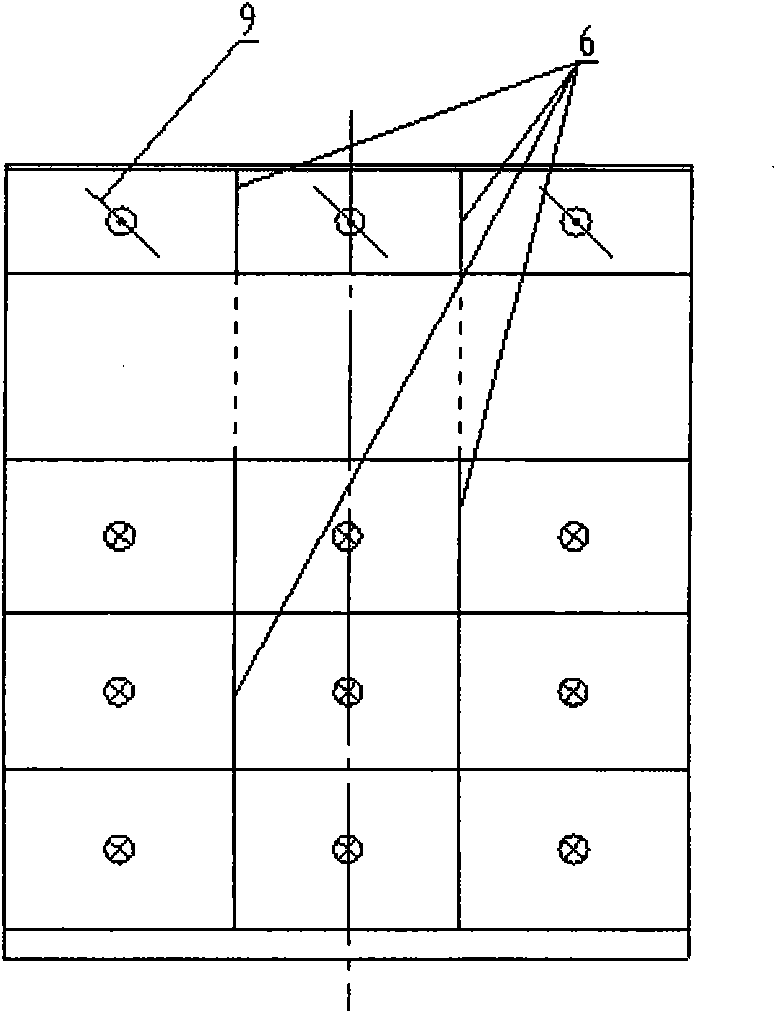

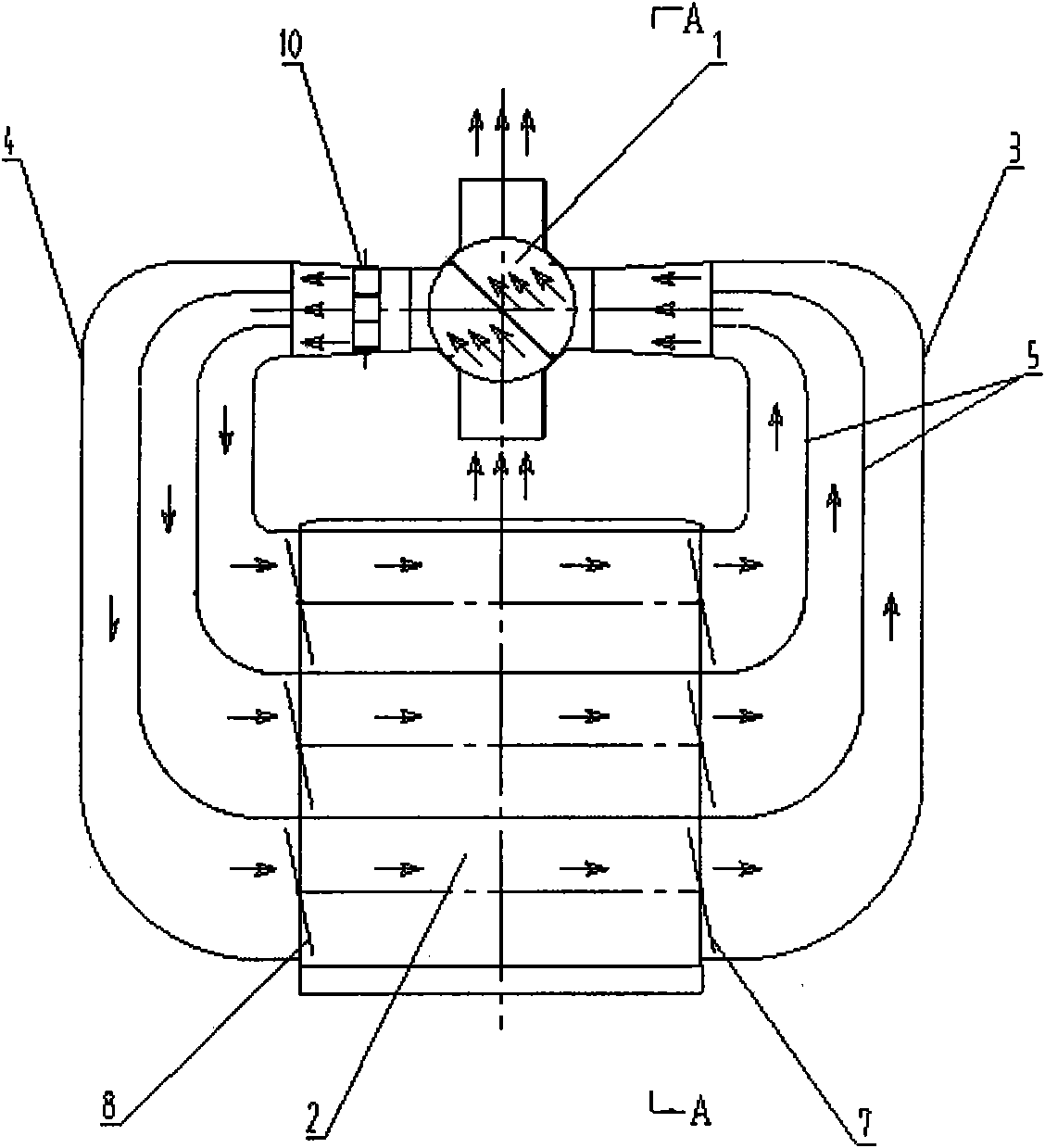

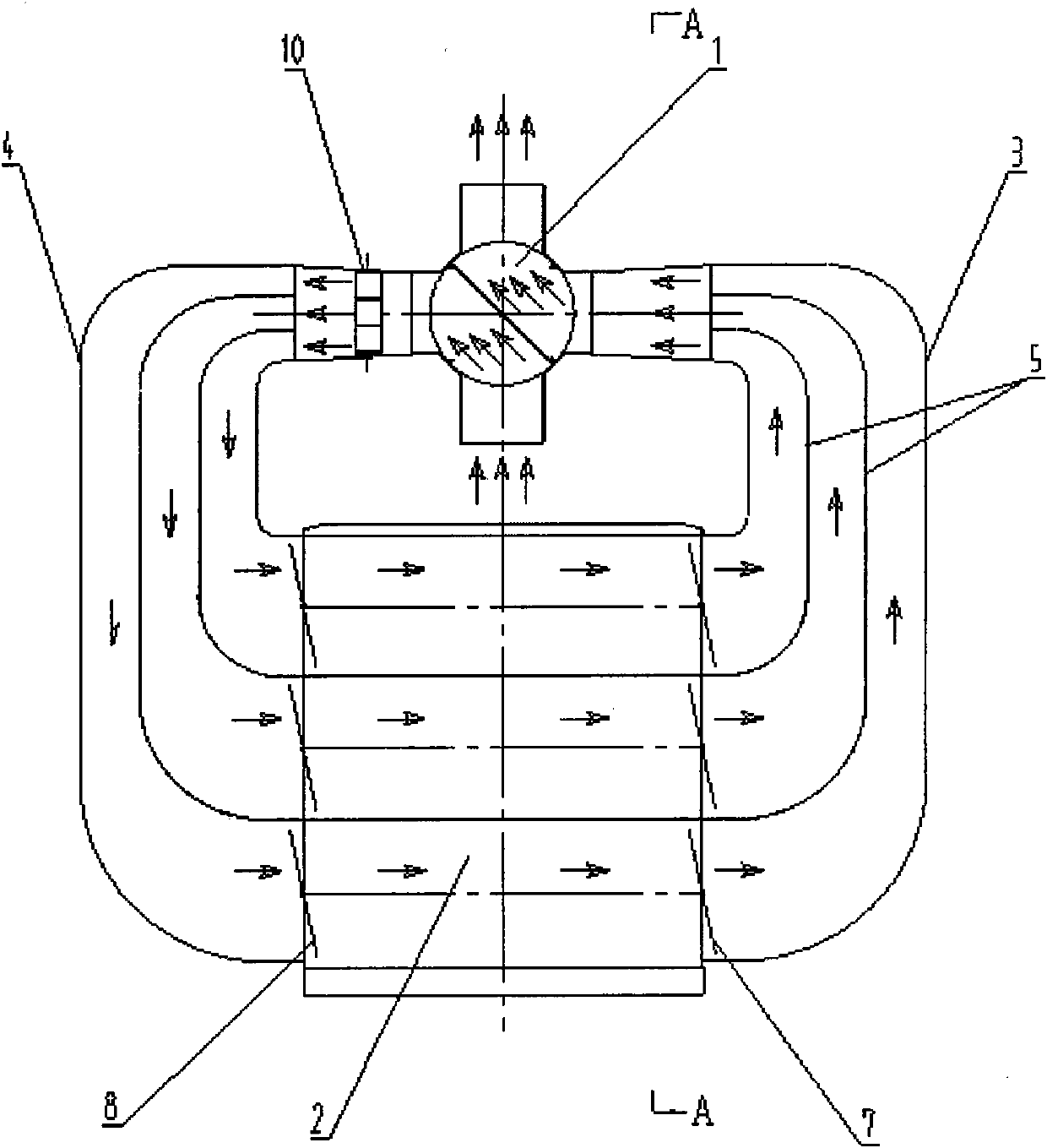

[0013] refer to figure 1 and figure 2 , a coal mine exhaust air oxidation device inlet and exhaust channel segmentation method, including the oxidation device inlet and exhaust reversing valve 1, oxidation bed 2, right air channel 3 and left air channel 4. The right air channel 3 and the left air channel 4 entering the oxidation bed 2 are provided with a splitter and an air volume regulating mechanism to evenly distribute the air flow in both vertical and horizontal directions so as to maintain the methane concentration and air volume in the oxidation bed 2. Uniform intake and discharge prevents methane drift and temperature field drift in the oxidation bed after the exhaust air is heated in the oxidation device, and effectively maintains the continuous and stable operation of the oxidation device.

[0014] The right air channel 3 and the left air channel 4 on the oxidation bed 2 are provided with dividing partitions, which are divided vertically and horizontally by the vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com