Device and method for regenerating a particle filter arranged in the exhaust tract of an internal combustion engine

A particle filter, internal combustion engine technology, applied in the direction of exhaust device, electronic control of exhaust treatment device, diagnosis device of exhaust treatment device, etc. It can reduce the regeneration temperature, reduce carbon monoxide emissions, and shorten the regeneration duration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

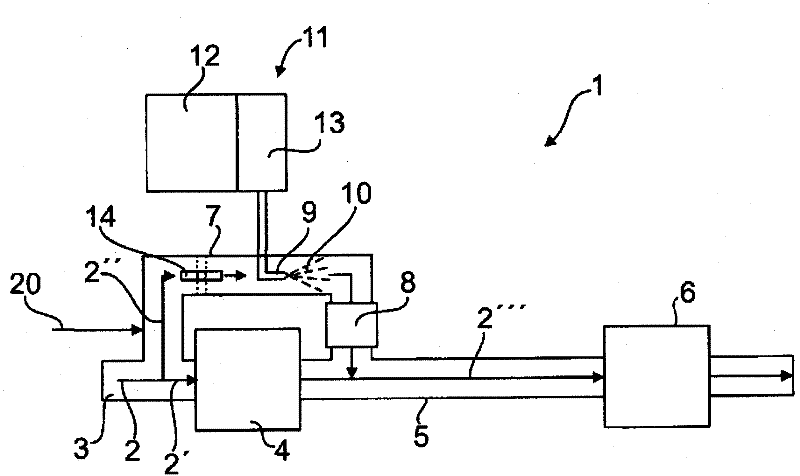

[0060] exist image 3 shows a first exemplary embodiment according to the invention, in which an exhaust gas flow 2 is led to a NO oxidation catalytic converter 4 by means of a delivery line 3 in an exhaust tract 1 of an internal combustion engine, not shown here, in particular a diesel internal combustion engine . From this NO oxidation catalytic converter 4 an outlet line 5 leads to a particle filter 6 .

[0061] Upstream of the NO oxidation catalyst 4 , a branch line 7 branches off from the delivery line 3 and opens downstream of the NO oxidation catalyst 4 into the outlet line 5 .

[0062] In this branch line 7, an HC oxidation catalyst 8 is arranged as a heating device. In addition, nozzles 9 are arranged upstream of the HC oxidation catalyst 8 in the branch line 7 , by means of which fuel 10 can be injected as reducing agent into the branch line 7 upstream of the HC oxidation catalyst 8 .

[0063] For this reason, the nozzle 9 is part of a metering device 11 which, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com