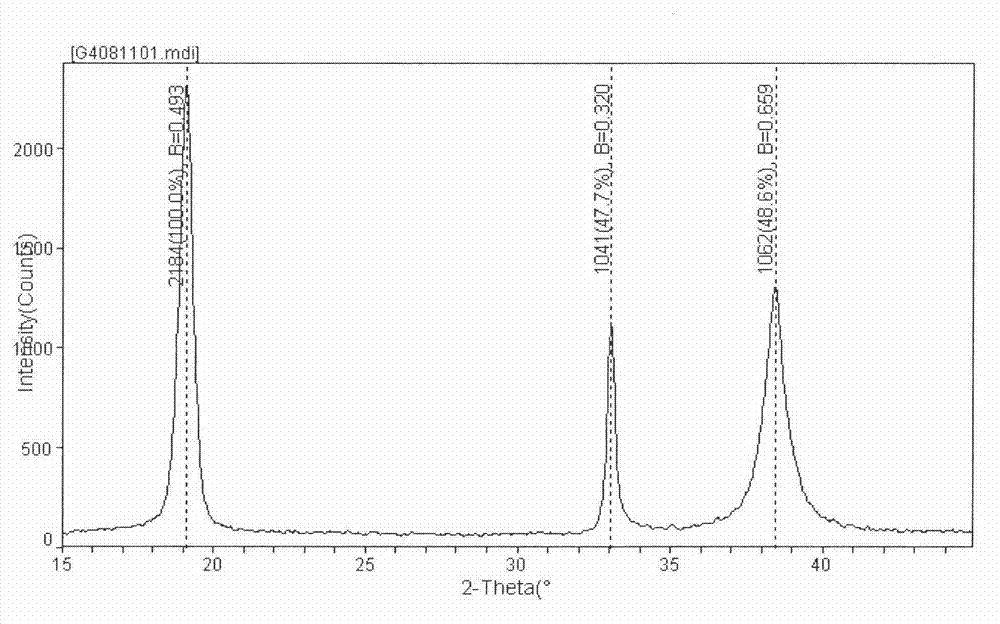

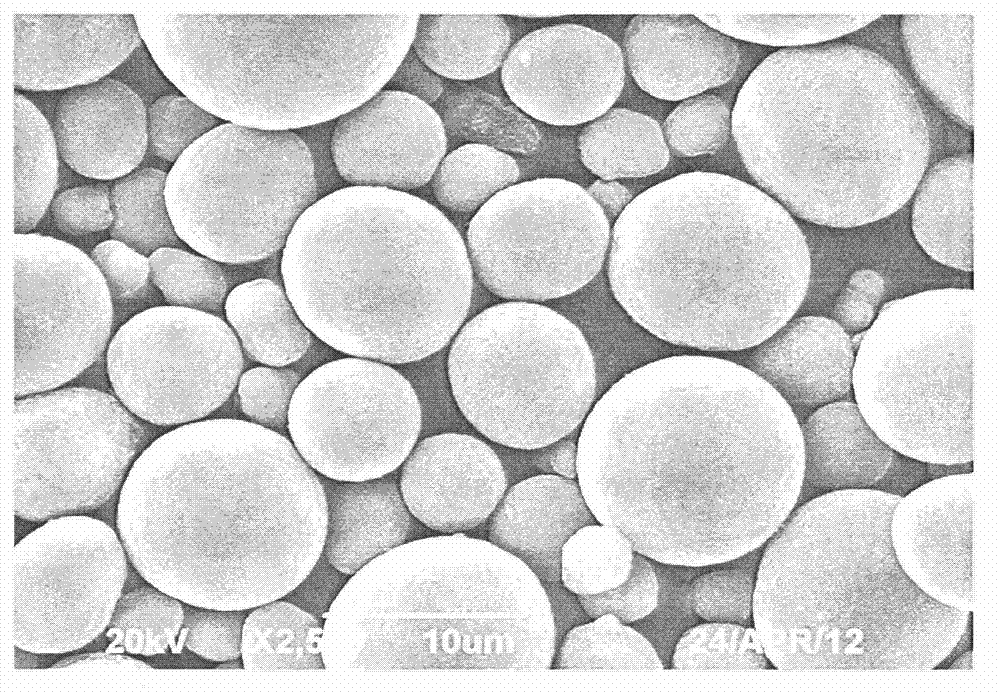

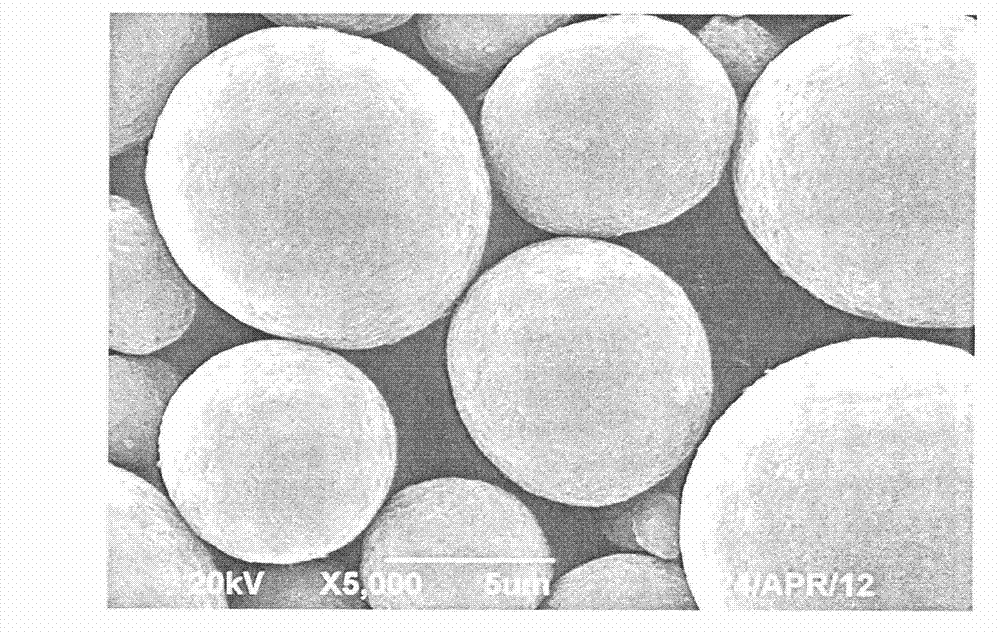

Technology for producing covering cobalt spherical nickelous hydroxide through continuous method

A spherical nickel hydroxide and continuous method technology, applied in nickel oxide/nickel hydroxide, etc., can solve the problems of low bulk tap density, non-continuous production, low production efficiency, etc., and achieve low production cost, complete oxidation, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] ①. Preparation of reaction solution, oxidant and compressed air.

[0029] To prepare cobalt sulfate solution, add pure water into the preparation tank, start stirring, put a certain amount of cobalt sulfate into the preparation tank, and then replenish water to a sufficient amount; after stirring for one hour, the cobalt salt is fully dissolved and then sampled for testing. The cobalt concentration is at Pumped into the storage tank at 68g / L.

[0030] Prepare sodium hydroxide solution, add pure water into the preparation tank, and start stirring, put a certain amount of sodium hydroxide into the preparation tank, and then replenish the water to a sufficient amount; after stirring for one hour, the sodium hydroxide is fully dissolved and then sampled for testing , the sodium hydroxide concentration is pumped into the storage tank at 15.5%.

[0031] To prepare ammonia solution, add pure water to the preparation tank, turn on the circulation pump, inject a certain amount ...

Embodiment 2

[0043] ①. Preparation of reaction solution, oxidant and compressed air.

[0044] To prepare cobalt sulfate solution, add pure water into the preparation tank, start stirring, put a certain amount of cobalt sulfate into the preparation tank, and then replenish water to a sufficient amount; after stirring for one hour, the cobalt salt is fully dissolved and then sampled for testing. The cobalt concentration is at 72g / L when pumped into the storage tank.

[0045] Prepare sodium hydroxide solution, add pure water into the preparation tank, and start stirring, put a certain amount of sodium hydroxide into the preparation tank, and then replenish the water to a sufficient amount; after stirring for one hour, the sodium hydroxide is fully dissolved and then sampled for testing , the sodium hydroxide concentration is pumped into the storage tank at 14.5%.

[0046]To prepare ammonia solution, add pure water to the preparation tank, turn on the circulation pump, inject a certain amount...

Embodiment 3

[0057] ①. Preparation of reaction solution, oxidant and compressed air.

[0058] To prepare cobalt sulfate solution, add pure water into the preparation tank, start stirring, put a certain amount of cobalt sulfate into the preparation tank, and then replenish water to a sufficient amount; after stirring for one hour, the cobalt salt is fully dissolved and then sampled for testing. The cobalt concentration is at 70g / L when pumped into the storage tank.

[0059] Prepare sodium hydroxide solution, add pure water into the preparation tank, and start stirring, put a certain amount of sodium hydroxide into the preparation tank, and then replenish the water to a sufficient amount; after stirring for one hour, the sodium hydroxide is fully dissolved and then sampled for testing , the sodium hydroxide concentration is pumped into the storage tank at 15%.

[0060] To prepare ammonia solution, add pure water to the preparation tank, turn on the circulation pump, inject a certain amount ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com