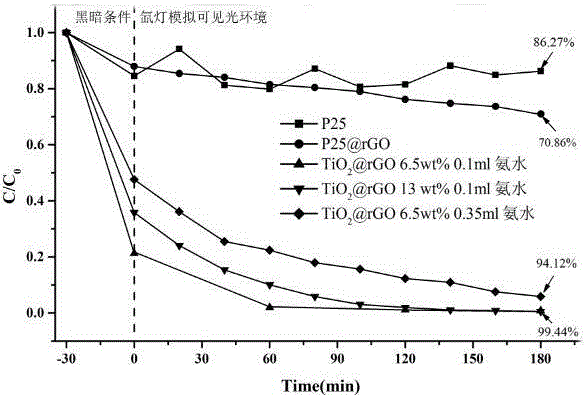

Preparation method and application of graphene and titanium dioxide photo-catalysis nano-crystals

A titanium dioxide, photocatalytic technology, applied in chemical instruments and methods, physical/chemical process catalysts, nanotechnology, etc., can solve the problems of slow degradation activity, unintuitive, long reaction time, etc., to slow down the reaction process and achieve uniform dispersion. , the effect of slowing down the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method for graphene titanium dioxide photocatalytic nanocrystals, comprising the following steps:

[0038] a. Put 2g of graphite powder and 1.2g of sodium nitrate in a single-necked flask, add 76ml of concentrated sulfuric acid, seal the flask and disperse it ultrasonically for 10 minutes, then place the flask in an ice bath and stir;

[0039] b. Slowly add 8.8g of potassium permanganate into the flask, stir in an ice bath environment for 8 hours, then slowly add 72ml of ultrapure water dropwise, then place the flask in a water bath, adjust the temperature to 50°C and stir the reaction After 8 hours, adjust the temperature of the water bath to 35°C and continue the reaction for 12 hours;

[0040] c. Slowly add 22ml of hydrogen peroxide into the flask, and continue to react for 3 hours at the temperature of 35°C water bath, then wash with hydrochloric acid under high-speed centrifugation, and then continue to wash with pure water and ethanol until the pH of...

Embodiment 2

[0045] A preparation method for graphene titanium dioxide photocatalytic nanocrystals, comprising the following steps:

[0046] a. Put 2g of graphite powder and 1.2g of sodium nitrate in a single-necked flask, add 76ml of concentrated sulfuric acid, seal the flask and disperse it ultrasonically for 15 minutes, then place the flask in an ice bath and stir;

[0047] b. Slowly add 8.8g of potassium permanganate into the flask, stir in an ice bath environment for 9 hours, then slowly add 72ml of ultrapure water dropwise, then place the flask in a water bath, adjust the temperature to 50°C and stir the reaction After 9 hours, adjust the temperature of the water bath to 35°C and continue the reaction for 12 hours;

[0048] c. Slowly add 22ml of hydrogen peroxide into the flask, and continue to react for 3 hours at the temperature of 35°C water bath, then wash with hydrochloric acid under high-speed centrifugation, and then continue to wash with pure water and ethanol until the pH of t...

Embodiment 3

[0054] A preparation method for graphene titanium dioxide photocatalytic nanocrystals, comprising the following steps:

[0055] a. Put 2g of graphite powder and 1.2g of sodium nitrate in a single-necked flask, add 76ml of concentrated sulfuric acid, seal the flask and disperse it ultrasonically for 20 minutes, then place the flask in an ice bath and stir;

[0056] b. Slowly add 8.8g of potassium permanganate to the flask, stir in an ice bath for 11 hours, then slowly add 72ml of ultrapure water dropwise, then place the flask in a water bath, adjust the temperature to 50°C and stir the reaction After 11 hours, adjust the temperature of the water bath to 35°C and continue the reaction for 12 hours;

[0057] c. Slowly add 22ml of hydrogen peroxide into the flask, and continue to react for 3 hours at the temperature of 35°C water bath, then wash with hydrochloric acid under high-speed centrifugation, and then continue to wash with pure water and ethanol until the pH of the mixture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com