Preparation method for cathode material Na3V2(PO4)3/C of sodium ion battery

A sodium-ion battery and cathode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of inability to obtain electrochemical properties of sodium vanadium phosphate, inability to guarantee high-valence vanadium reduction, and impurities in the product, etc., and achieve excellent rate Discharge performance, good application prospects, simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

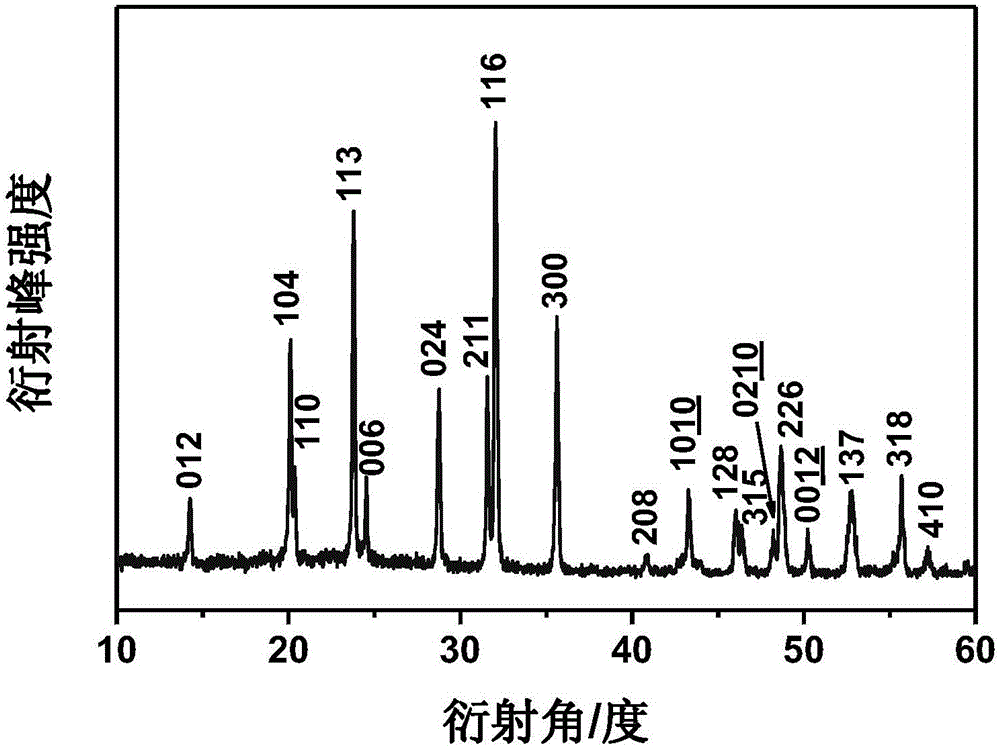

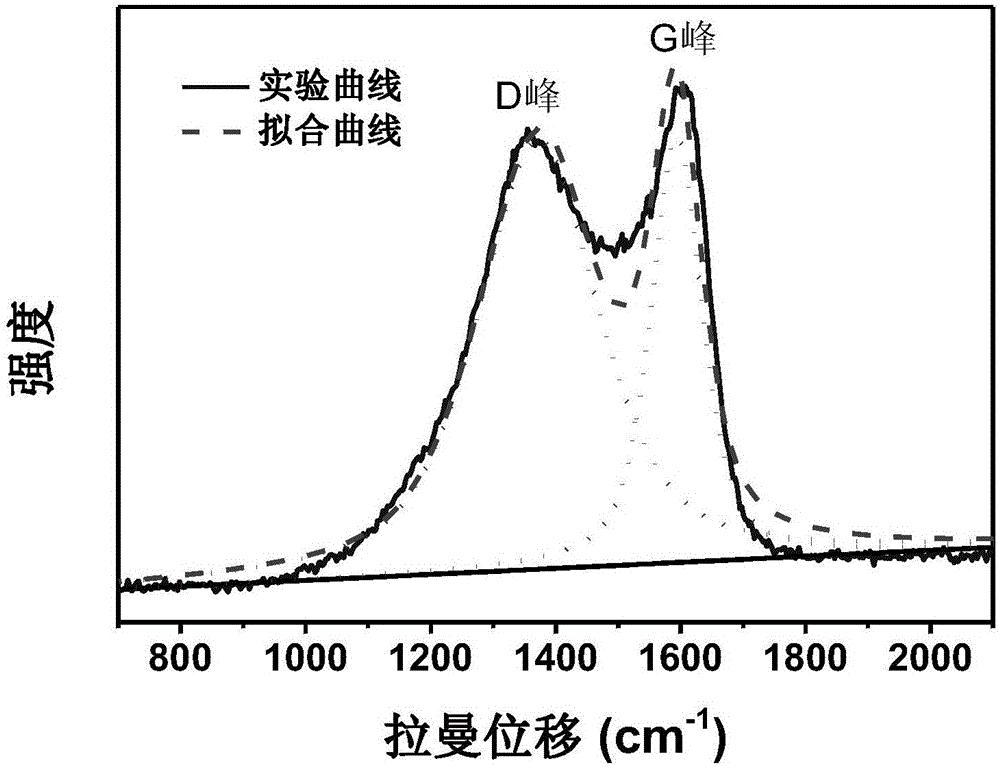

[0024] Taking sodium dihydrogen phosphate, vanadium pentoxide and oxalic acid as raw materials, wherein the mol ratio of sodium, vanadium and phosphorus is 3:2:3, and the mol ratio of oxalic acid and vanadium pentoxide in terms of vanadium is 6:1. The raw material was mechanically ball milled for 6 hours to obtain the precursor. Transfer the precursor to a tube furnace, raise the temperature to 800 °C in a nitrogen atmosphere, and keep the temperature constant for 12 hours to obtain Na 3 V 2 (PO 4 ) 3 / C material, analyzed by X-ray diffraction ( figure 1 ) determined that the method synthesized Na 3 V 2 (PO 4 ) 3 , the space group is R-3c. figure 2 A Raman spectrum of the resulting material was shown, confirming the presence of carbon in the material.

Embodiment 2

[0026] Using sodium carbonate, ammonium dihydrogen phosphate, vanadium pentoxide, and oxalic acid as raw materials, wherein the molar ratio of sodium, vanadium, and phosphorus is 3:2:3, and the molar ratio of oxalic acid and vanadium pentoxide in terms of vanadium is 4: 1. Mechanical ball milling of raw materials for 12 hours to obtain precursors. The precursors were transferred to a tube furnace under Ar / H 2 (H 2 The content is 10%) in the atmosphere, the temperature is raised to 850 ° C, and the temperature is kept constant for 8 hours to obtain Na 3 V 2 (PO 4 ) 3 / C material.

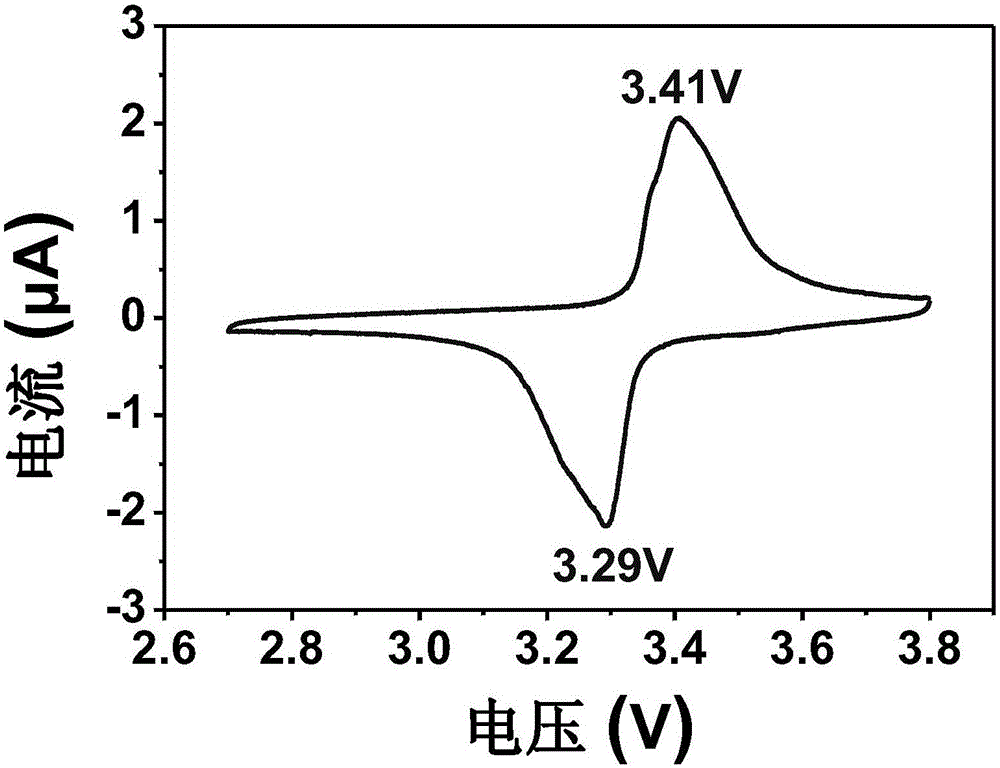

[0027] According to Na 3 V 2 (PO 4 ) 3 / C, acetylene black, PVDF mass ratio is 80:10:10 to prepare electrode, with metal sodium as counter electrode, 1mol / LNaPF 6 Ethylene carbonate / diethyl carbonate (volume ratio 1:1) is the electrolyte, and the separator is cellgard2035. The battery is assembled in the glove box and subjected to cyclic voltammetry test. The voltage range is 2.7-3.8V, and ...

Embodiment 3

[0029] Using sodium dihydrogen phosphate, vanadium pentoxide, oxalic acid, and citric acid as raw materials, wherein the molar ratio of sodium, vanadium, and phosphorus is 3:2:3, and the molar ratio of oxalic acid and vanadium pentoxide in terms of vanadium is 3: 1. The molar ratio of citric acid and vanadium pentoxide in terms of vanadium is 1:1, and the raw materials are mechanically ball milled for 12 hours to obtain the precursor. Transfer the precursor to a tube furnace, raise the temperature to 600°C in a nitrogen atmosphere, and keep the temperature constant for 20 hours to obtain Na 3 V 2 (PO 4 ) 3 / C material.

[0030] According to Na 3 V 2 (PO 4 ) 3 / C, acetylene black, PVDF mass ratio is 70:20:10 to prepare electrode, with metal sodium as counter electrode, 1mol / LNaClO 4 PC is the electrolyte, and the separator is cellgard2035. The battery is assembled in a glove box and tested for its charge and discharge rate. The voltage range is 2-4V, and the current den...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com