Aqueous zinc ion battery and preparation method and application thereof

A zinc-ion battery, water system technology, applied in batteries, battery electrodes, secondary batteries, etc., can solve the problems of Mn dissolution of electrode materials, zinc dendrites, etc., to improve rate performance, improve electrical conductivity, and alleviate the problem of volume effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Preparation of the positive active material birnessite / carbon composite:

[0058] Dissolve 2.265g of anhydrous manganese sulfate in 50ml of water, add 200mg of carbon nanotubes, and ultrasonically disperse for 30 minutes at a power of 100W to obtain mixed solution A; dissolve 2.16g of sodium hydroxide in 90ml of water, add 10ml of hydrogen peroxide (30wt %) to obtain mixed solution B; at a stirring speed of 2000rpm, dissolve B and add it dropwise to A at a speed of 1mL / min, age for 24h, filter with suction, wash with water, ethanol, water and ethanol in sequence, and filter with suction Half an hour later, it was transferred to an oven at 50° C. and dried for 24 hours to obtain a birnessite / carbon composite material, wherein carbon nanotubes accounted for 10 wt% of the birnessite / carbon composite material.

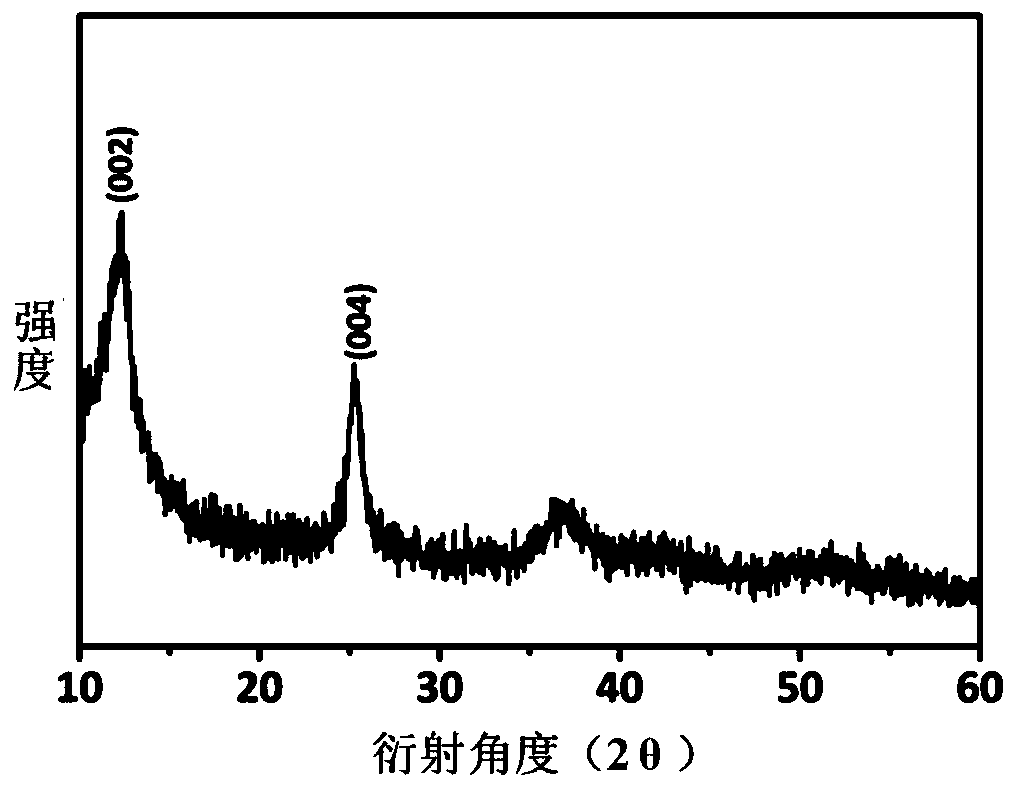

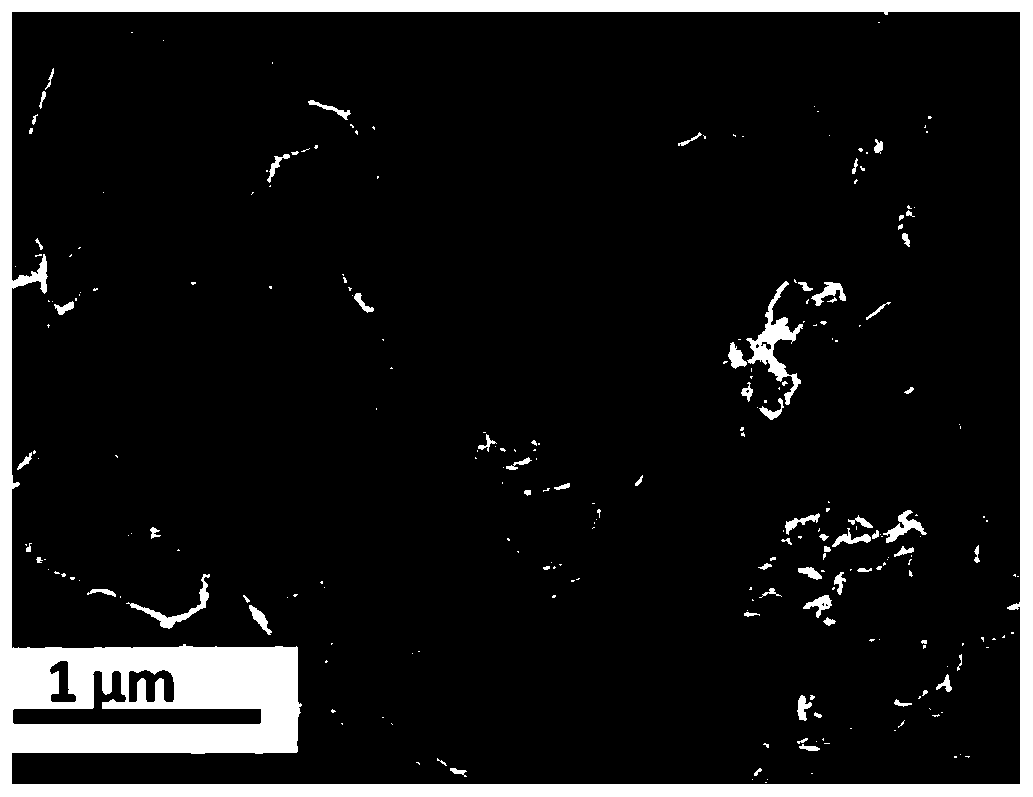

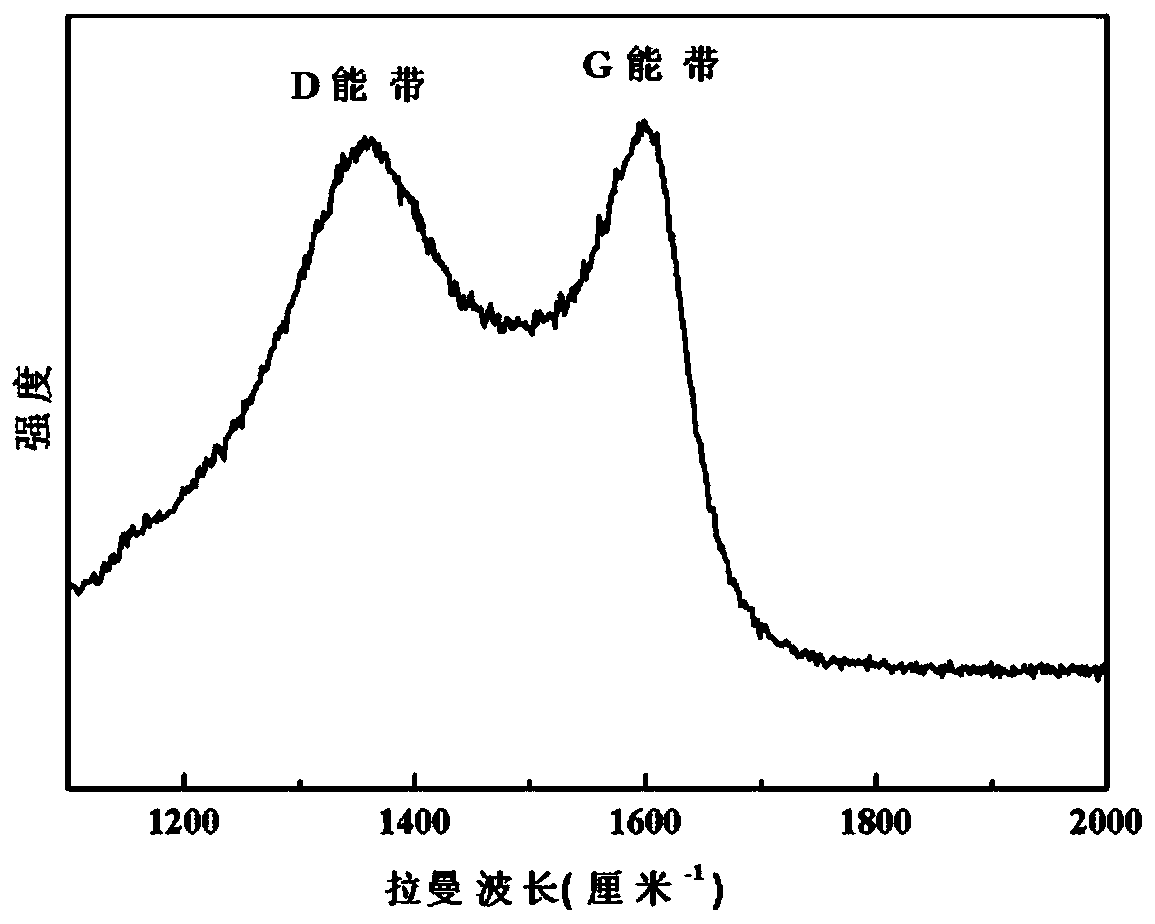

[0059] Adopt X-ray powder diffractometer to carry out X-ray diffraction analysis to the birnessite / carbon composite material of the present embodiment, spectrogram ...

Embodiment 2

[0063] Preparation of the positive active material birnessite / carbon composite:

[0064] Dissolve 12.55g of manganese nitrate tetrahydrate in 50 ml of water, add 100 mg of graphene, and disperse ultrasonically for 30 minutes at a power of 100W to obtain mixed solution A; dissolve 3.85mL of ammonia water in 90 ml of water, add 15.3 ml of hydrogen peroxide (30wt%) to obtain Mixed solution B; under stirring at 2000rpm, add mixed solution B dropwise to mixed solution A at a rate of 1mL / min, age for 20h, filter with suction, wash with water, ethanol, water and ethanol in sequence, and filter with suction for half an hour Afterwards, it was transferred to an oven at 50°C and dried for 20 hours to obtain a birnessite / carbon composite material, wherein graphene accounted for 1 wt% of the birnessite / carbon composite material.

Embodiment 3

[0066] Preparation of the positive active material birnessite / carbon composite:

[0067] Dissolve 6.1273g of manganese acetate in 50 ml of water, add 1 gram of graphite, and disperse ultrasonically for 30 minutes at a power of 100W to obtain mixed solution A; dissolve 2.80 g of sodium hydroxide in 90 ml of water, add 12.3 ml of hydrogen peroxide (30wt%) to obtain a mixed Liquid B; under stirring at 2000rpm, dissolve B and add dropwise to A at a rate of 1mL / min, age for 16h, filter with suction, wash with water, ethanol, water, and ethanol in sequence, and transfer to Dry in an oven at 50° C. for 18 hours to obtain the birnessite / carbon composite material, wherein graphite accounts for 20 wt% of the birnessite / carbon composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com