Semiconductor device manufacturing process and equipment

A technology of semiconductors and devices, which is applied in the field of semiconductor device manufacturing and can solve problems such as complex processing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

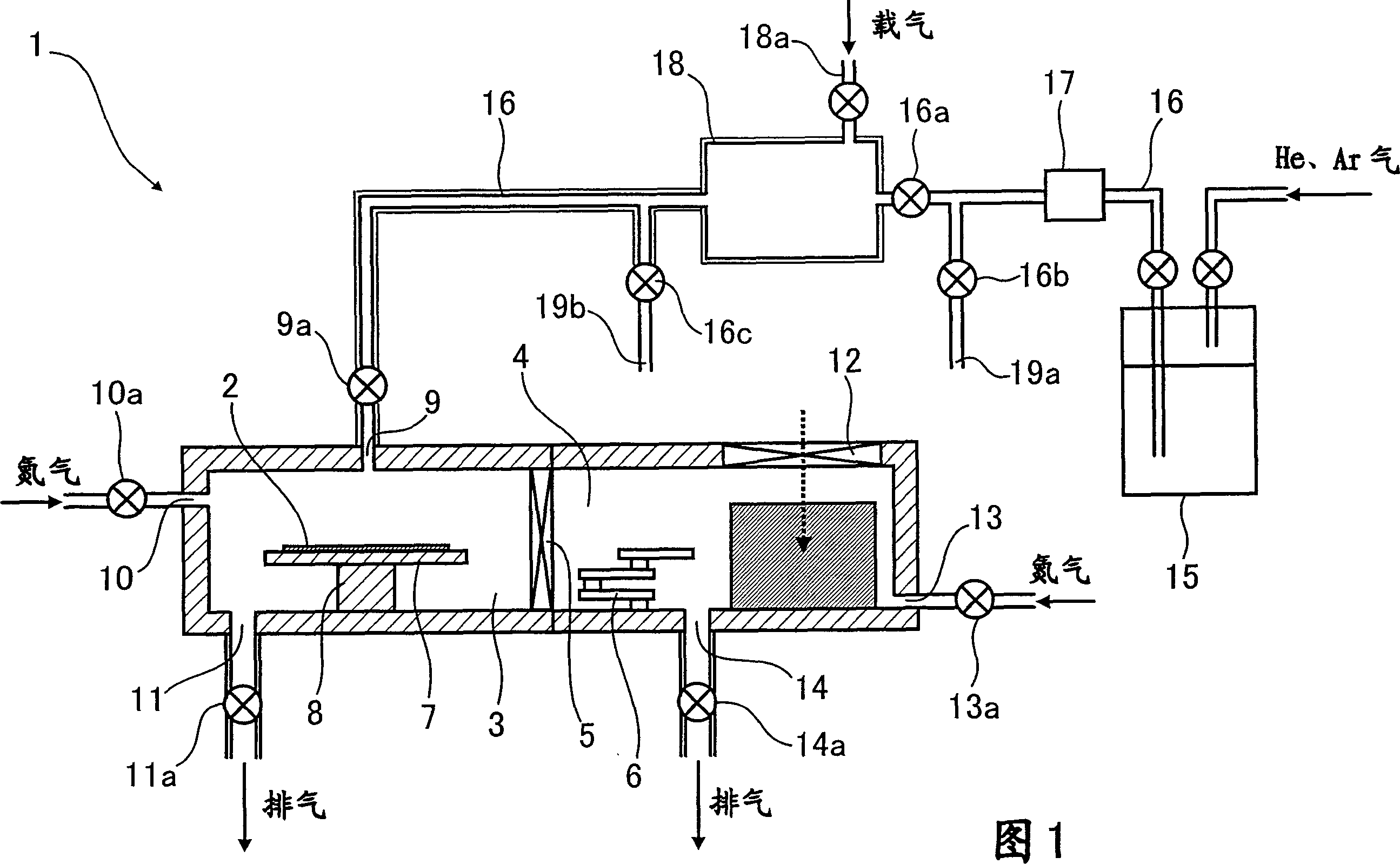

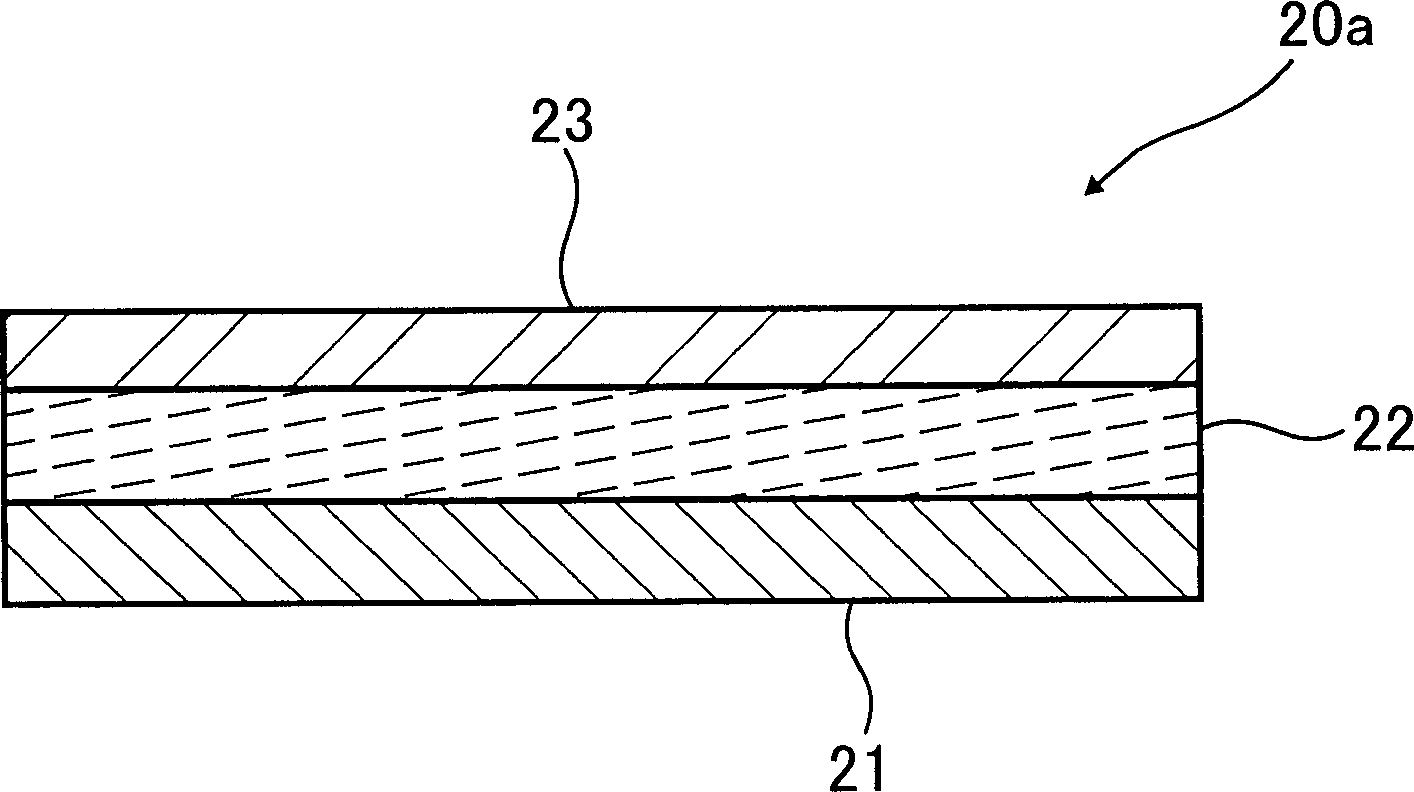

[0035] Embodiments of the present invention are described below with reference to the drawings.

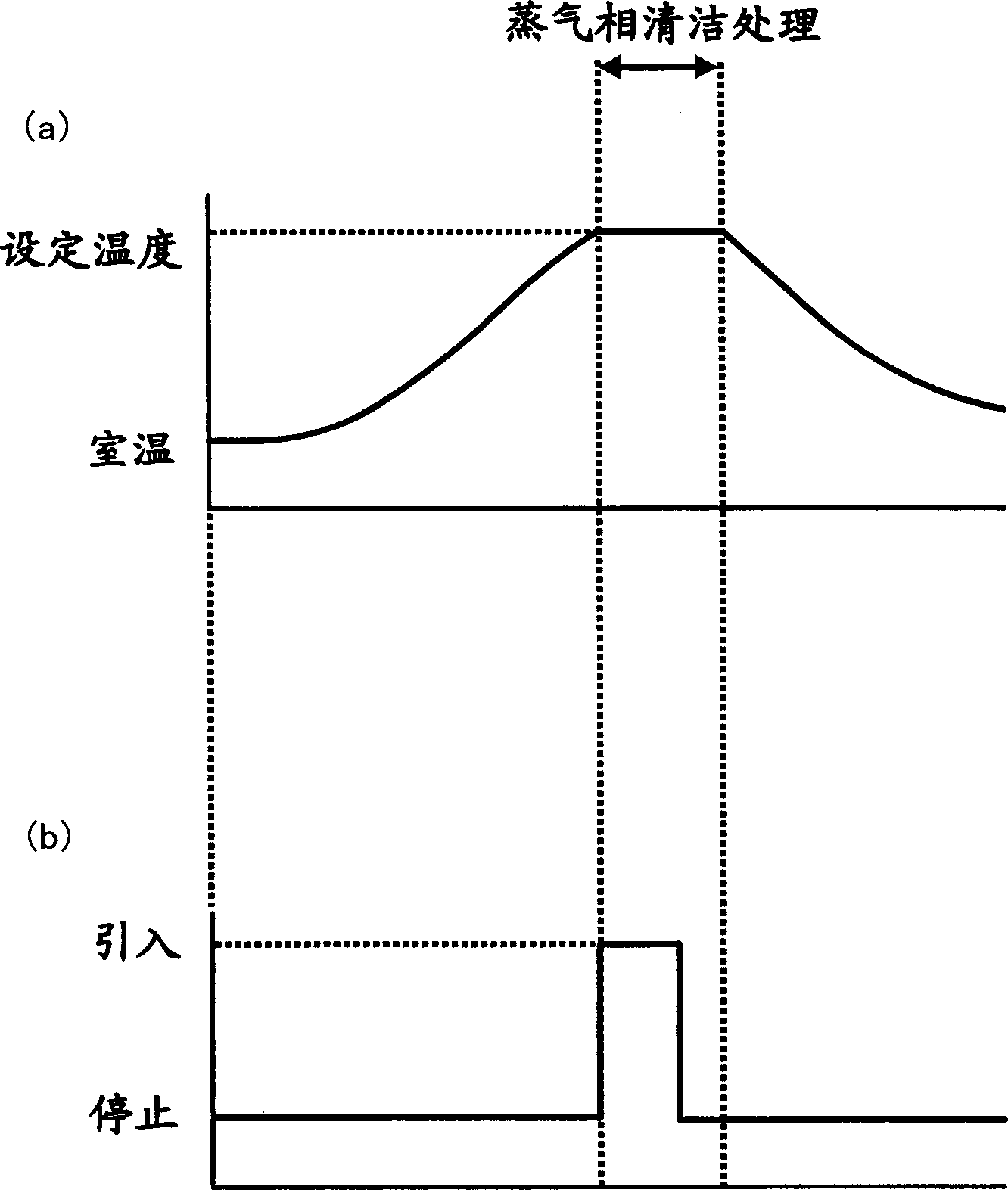

[0036] First, the vapor phase cleaning treatment in the semiconductor device manufacturing method of the present invention will be described. In the present invention, gaseous carboxylic acid (RCOOH, where R=H; C N h 2N+1 、C N h M x 2N-M+1 , wherein N and M are natural numbers, and X=F, CL) reduce copper oxides such as copper oxide and cuprous oxide produced on copper electrodes and leads.

[0037] Carboxylic acid can act on copper oxide as a reducing agent, that is, carboxylic acid can reduce copper oxide to metallic copper (Cu) and generate carbon dioxide (CO 2 ) and water (H 2 O). For example, if formic acid (HCOOH) is used as carboxylic acid, copper oxide and cuprous oxide can be reduced to metallic copper, and the chemical reaction formulas are respectively and .

[0038] If the H produced according to the above reaction 2 O is gaseous, and the reaction s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com