Preparation method of non-metallic element doped nano zero-valent nickel loaded carbon fiber composite material

A technology of fiber composite materials and non-metallic elements, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve problems such as complex operations, achieve good flexibility, large specific surface area, and inhibit oxidation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Pretreatment of carbon fiber cloth

[0034] Arrange 0.13g of carbon fibers in ethanol solution to ultrasonically remove surface impurities, then place them in nitric acid solution with a mass concentration of 32%, soak them at room temperature for 3 hours, wash them with water until they are neutral, and then dry them to obtain the modified carbon fibers modified by nitric acid. Activated carbon fiber cloth;

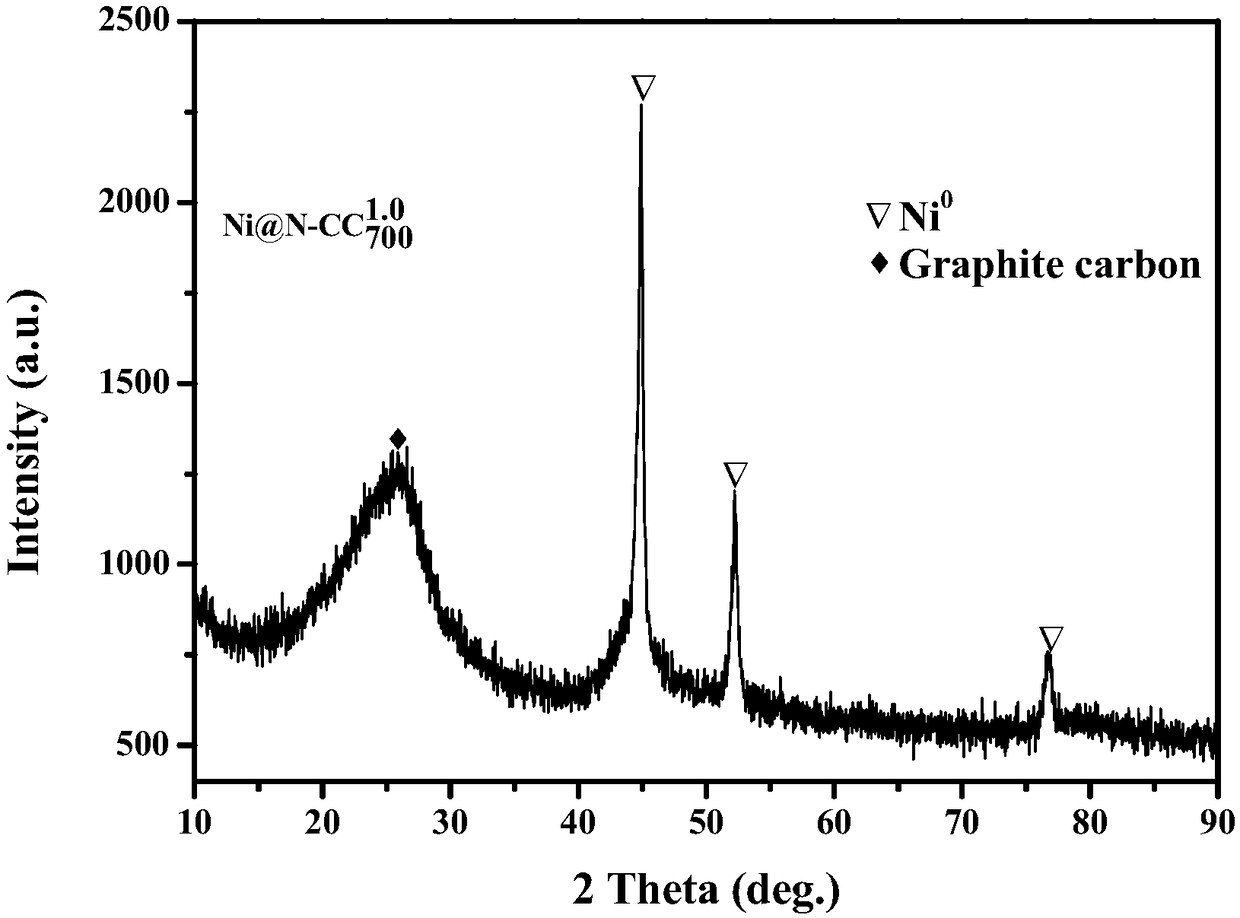

[0035] (2) Zero-valent nickel (Ni 0 ) loading of nanoparticles

[0036] The activated carbon fibers modified by nitric acid were arranged in a layer containing 2.3769g (10mmol) NiCl 2 ·6H 2 O(AR) and 1g polyvinylpyrrolidone in 20mL N,N-dimethylformamide (AR) solution, stirred for 200min, then transferred to a muffle furnace, pre-oxidized at 350°C for 2 hours to obtain a composite material precursor;

[0037] Weigh 1g (12mmol) of dicyandiamide in a quartz boat, spread the obtained precursor on the upper layer of dicyandiamide, and then transfer the whole to...

Embodiment 2

[0043] The preparation method of this embodiment is the same as that of Example 1, except that the calcining and pyrolysis process in step (2) is as follows: first, the temperature is raised to 400°C at 5°C / min, and the temperature is kept at a constant temperature for 2 hours; 800°C, constant temperature for 2 hours. After the reaction is finished, cool to room temperature to obtain nitrogen-doped nanometer zero-valent nickel (Ni 0 )Carbon fiber composite material.

[0044] The mass of the composite material prepared in this embodiment is ~0.134g, and the doping rate of nitrogen is ~4%.

Embodiment 3

[0046] The preparation method of this embodiment is the same as that of Example 1, except that the calcining and pyrolysis process in step (2) is as follows: first, the temperature is raised to 400°C at 5°C / min, and the temperature is kept at a constant temperature for 2 hours; 900°C, constant temperature for 2 hours. After the reaction is finished, cool to room temperature to obtain nitrogen-doped nanometer zero-valent nickel (Ni 0 )Carbon fiber composite material.

[0047] The mass of the composite material prepared in this example is ~0.133g, and the doping rate of nitrogen is ~4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com