Al-Si alloy preplating bi-coordinating agent acidic zinc dipping solution and preparation method thereof

An aluminum-silicon alloy, double-coordination technology, applied in the field of inorganic metal materials, can solve the problems of corrosion of aluminum-silicon alloy matrix, inability to meet the precision requirements of parts size, and unsuitable for aluminum-silicon alloys, achieving good coverage and beneficial to the body. Healthy, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following examples describe the present invention in more detail:

[0025] The configuration method of aluminum-silicon alloy pre-plating treatment double-coordinating agent acidic zinc dipping solution of the present invention is: (reagents used and distilled water are analytically pure)

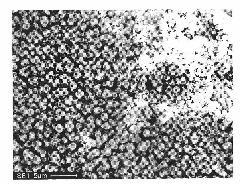

[0026] Taking the following acidic zinc dipping solution as an example, it consists of 100g / L zinc chloride, 20g / L sodium citrate, 20g / L ammonium bifluoride, 25g / L boric acid, 20g / L thiourea, and 2g sodium dodecylsulfonate. / L, 30% hydrogen peroxide 0.5mL / L, activated carbon 2g / L and distilled water to prepare an acidic zinc dipping solution, and the aluminum-silicon alloy sample was zinc dipped in this solution.

[0027] 1) Get zinc chloride 100g / L and fully dissolve it with distilled water;

[0028] 2) Sodium citrate 20g / L is fully dissolved in distilled water to form a clear solution;

[0029] 3) Ammonium bifluoride 20g / L is fully dissolved in distilled water to form a clear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com