Technique for preparing nickel-iron alloy

A nickel-iron alloy and preparation technology, applied in the field of metallurgy, can solve the problems of long reduction time, high energy consumption, and low production efficiency, and achieve the effects of short reduction time, low energy consumption, and less dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

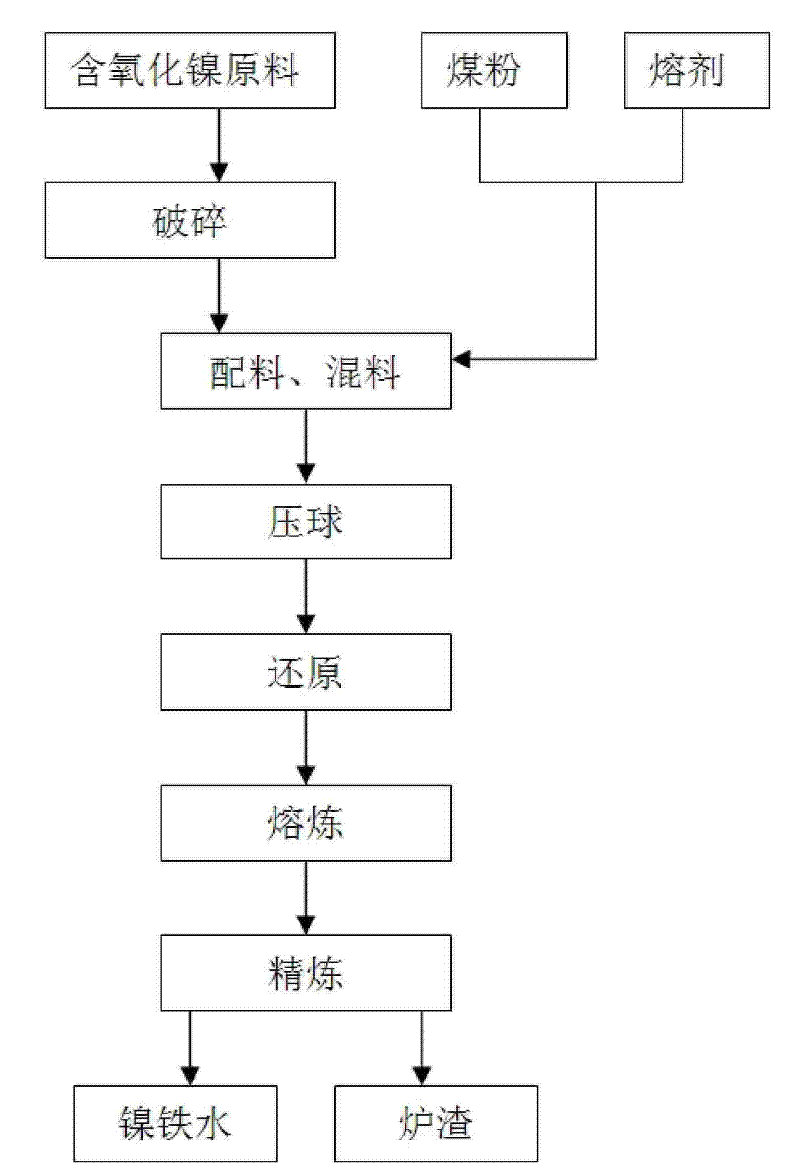

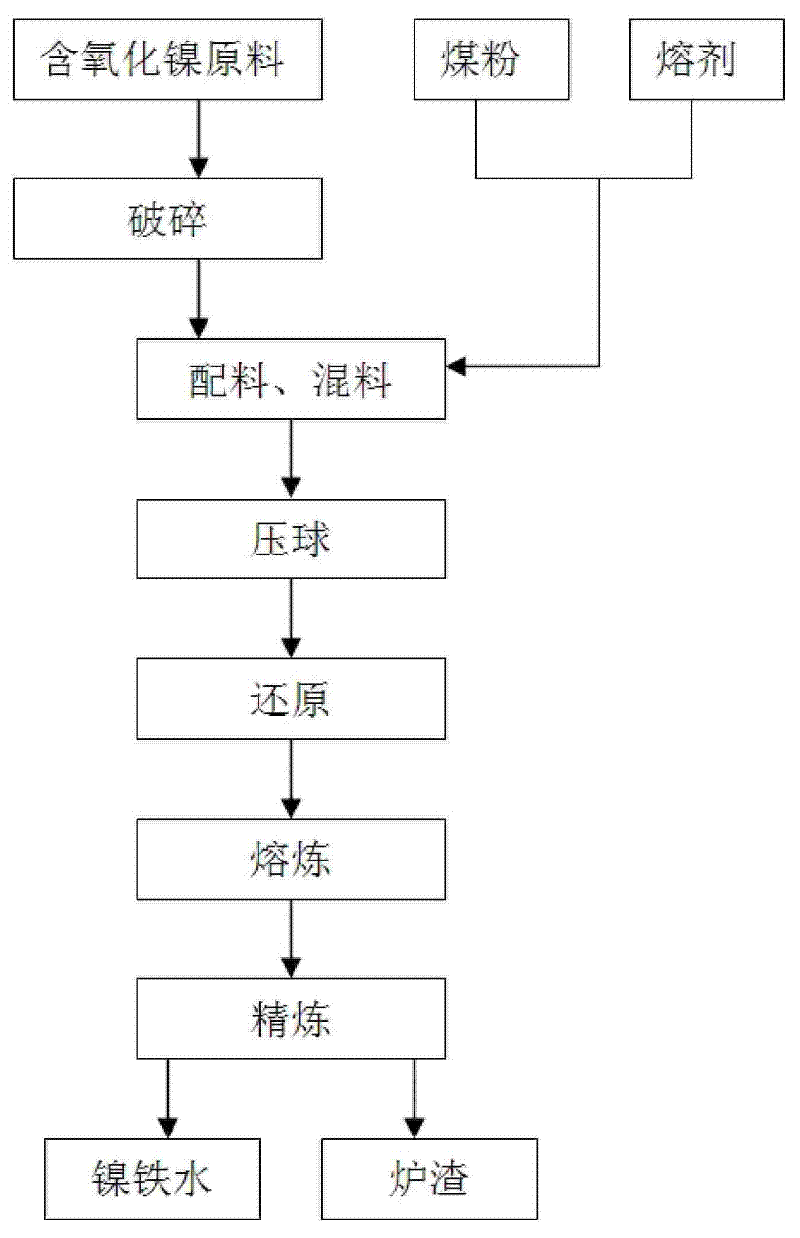

Method used

Image

Examples

Embodiment 1

[0025] In 1 ton of nickel oxide-containing raw materials (the composition is TFe 26.0%, Ni 1.88%, SiO 2 28.46%, CaO2.02%, MgO12.12%, Al 2 o 3 5.69%, P2 It is formulated for 0.6, and the particle size of coal powder and limestone is less than 5mm. The aforementioned 4 kinds of raw materials are mixed with water to form a mixture so that the water content is 7.8% of the weight of the mixture, and after uniform stirring, the pellets are pressed into pellets with a diameter of 30mm by a pressure molding machine. The pellets are sent into a rotary hearth furnace for reduction, the temperature of the rotary hearth furnace is controlled at 1300-1350° C., and the reduction time is 40 minutes to obtain metallized pellets. Then an electric arc furnace is used to melt and separate the metallized pellets, the melting and separation temperature is 1650° C., and the iron slag is removed to obtain a coarse nickel-iron alloy. Crude nickel-iron alloy is sent to the AOD refining furnace to...

Embodiment 2

[0028] Add coal powder 50kg, binder PVA 31.5kg and fluorite in 1 ton of nickel oxide-containing raw material (ingredients are the same as in Example 1), and the amount of fluorite is according to the alkalinity of the mixture CaO / SiO 2 Prepared for 0.9, coal powder, fluorite particle size 3 / t. The test results of product components are: Ni 17.8%, C 0.022%, S<0.03%, P<0.03%, and the balance is iron. The obtained nickel-iron alloy conforms to the ISO6501:1998 (E) standard grade requirement. In this embodiment, the reduction energy consumption of the rotary kiln is low, and there is less dust after reduction, and the furnace lining does not stick to the pellet charge.

Embodiment 3

[0030] In 1 ton of nickel oxide-containing raw materials (the composition is TFe 24.0%, Ni 1.98%, SiO 2 25.6%, CaO2.22%, MgO14.12%, Al 2 o 3 4.9%, P2 Prepared for 1.2, the particle size of coal powder and flux is 3 / t. The test results of product components are: Ni 18.1%, C 0.028%, S<0.025%, P<0.028%, and the balance is iron. The obtained nickel-iron alloy conforms to the ISO6501:1998 (E) standard grade requirement. In this embodiment, the reduction time of the rotary hearth furnace is short and the energy consumption is low. In addition, after the reduction of the rotary hearth furnace, there is less dust at the bottom of the furnace, and the furnace lining does not stick to the pellet charge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com