Method for extracting high-content nickel, chromium and iron from stainless steel dust

A stainless steel and dust technology, applied in the field of chromium and iron extraction with high nickel content, can solve the problems of uneconomical, increased enterprise cost, backward process, etc., and achieves the effect of optimizing atmosphere composition control, reducing production energy consumption, and streamlining the process route.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

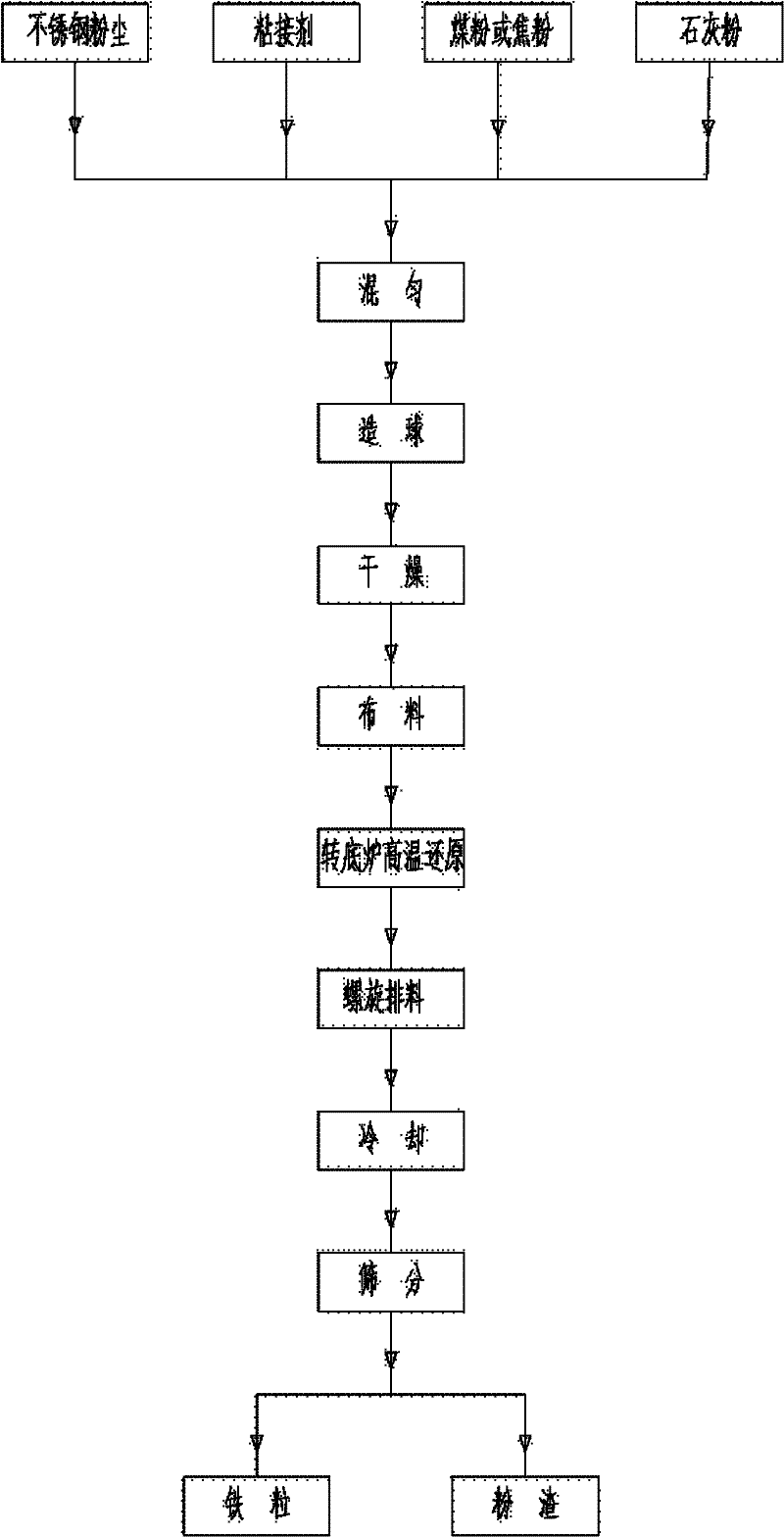

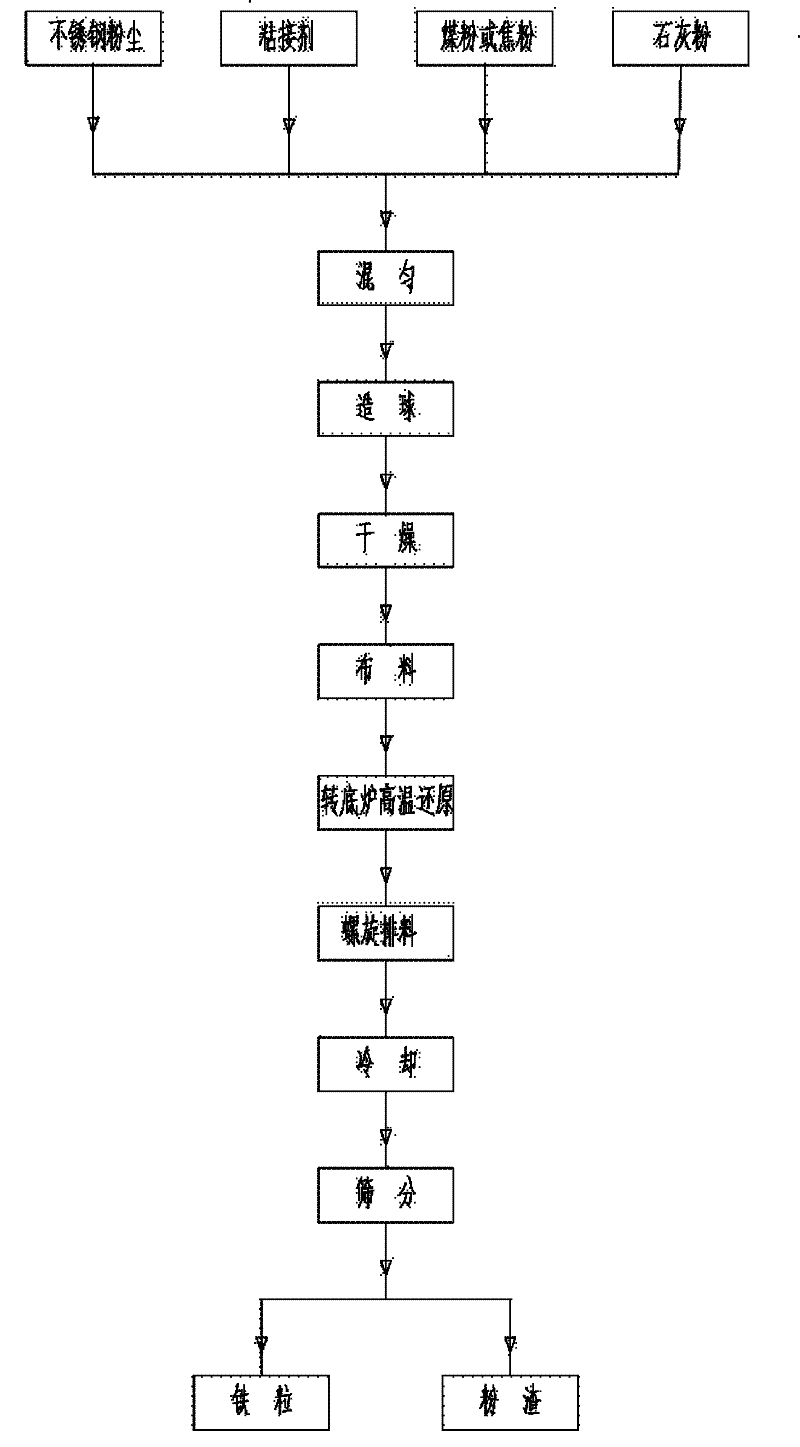

[0019] Such as figure 1 Shown, the method for extracting high nickel, chromium and iron from stainless steel dust of the present invention comprises the following steps:

[0020] 1) First prepare the raw materials, mix the raw materials such as stainless steel dust, coal powder, limestone powder and binder according to the following parts by weight: 100 parts of stainless steel dust, 18 parts of coal powder, 4 parts of limestone powder and 2 parts of binder share.

[0021] Among them: the composition of stainless steel dust is calculated by mass percentage: Cr 2 o 3 8%, NiO 6%, MnO 2%, Fe 2 o 3 55%, SiO 2 29%, stainless steel dust particle size ≤ 0.15mm;

[0022] The pulverized coal can be coke powder or non-coking coal, the ash content of the pulverized coal is ≤10%, and the particle size is ≤0.1mm; 2 O 1%, particle size <0.1mm.

[0023] The main components of the binder are as follows: Fe 2 o 3 2.65%, SiO 2 61%, Al 2 o 3 19.5%, CaO 0.55%, MgO 2.85%, H 2 O...

Embodiment 2

[0028] Such as figure 1 Shown, the method for extracting high nickel, chromium and iron from stainless steel dust of the present invention comprises the following steps:

[0029] 1) First prepare raw materials, mix stainless steel dust, coal powder, limestone powder and binder according to the following parts by weight: 100 parts of stainless steel dust, 16 parts of coal powder, 6 parts of limestone powder and 3 parts of binder share.

[0030] Among them: the composition of stainless steel dust is calculated by mass percentage: Cr 2 o 3 12%, NiO 4%, MnO 3%, Fe 2 o 3 45%, SiO 2 36%, stainless steel dust particle size ≤ 0.15mm;

[0031] Coal powder can be coke powder or non-coking coal, the ash content of coal powder is ≤10%, and the particle size is ≤0.1mm; the composition of coal powder is calculated by mass percentage: C 90%, S 0.8%, ash content 8%, H 2 O 1%, particle size <0.1mm.

[0032] The main components of the binder are as follows: Fe 2 o 3 2.65%, SiO 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com