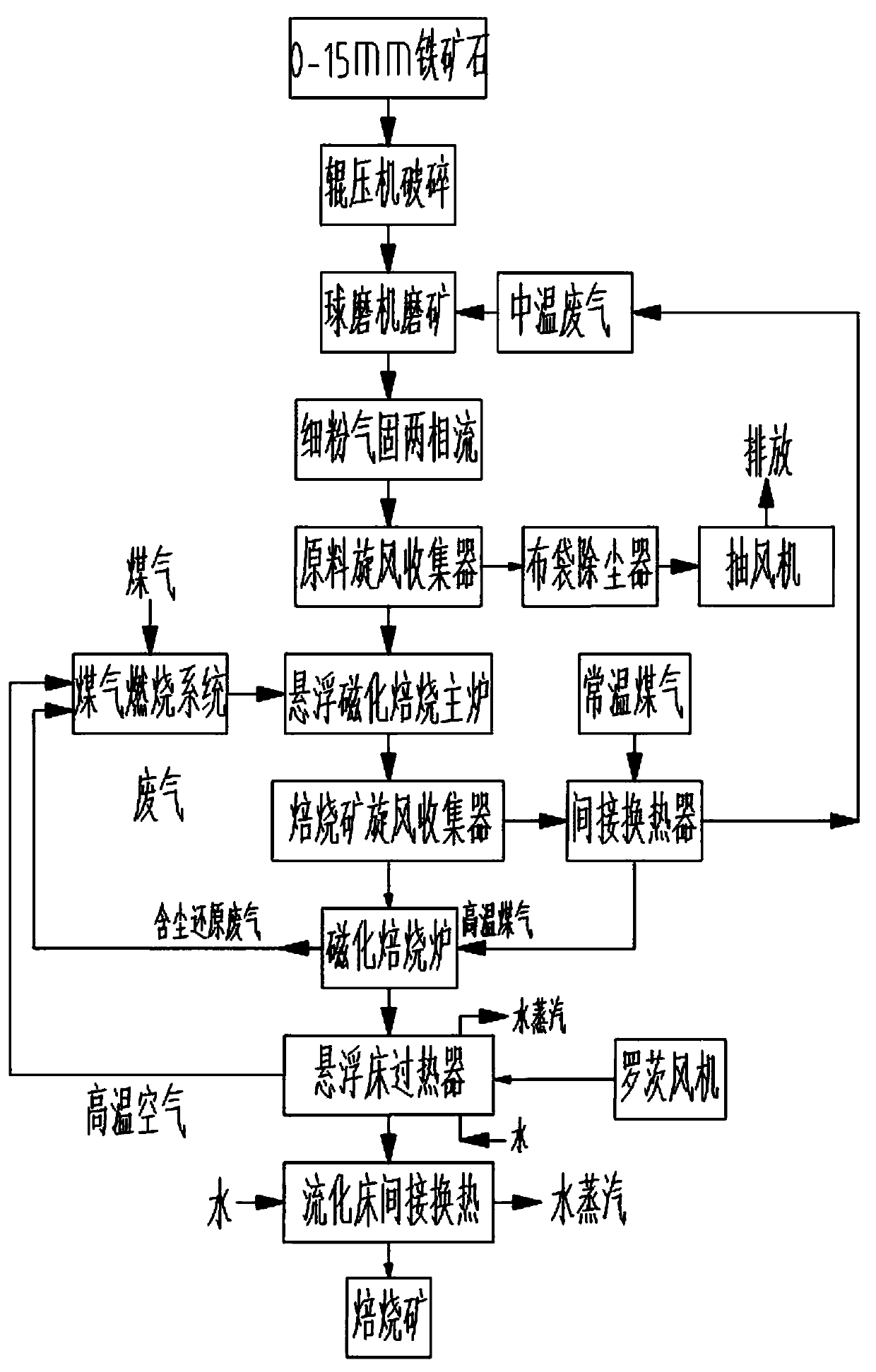

An integrated process and device for refractory iron ore dry grinding-suspension roasting

A technology for suspending roasting and iron ore, which is applied in the field of metallurgy and mineral engineering, can solve the problems of high water consumption, high production cost, long production process, etc., and achieve the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

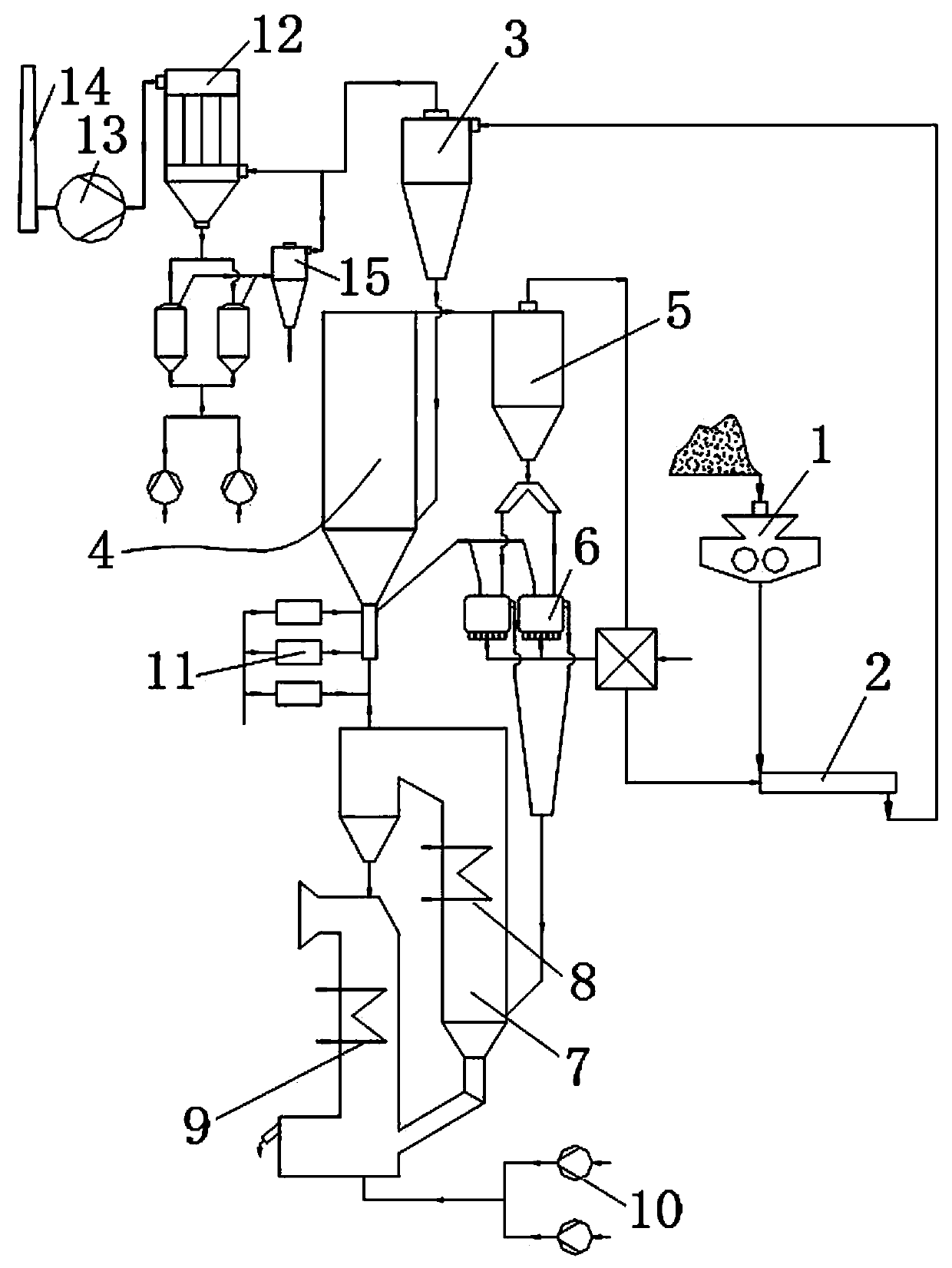

[0031] Below in conjunction with accompanying drawing, the present invention is explained and described in further detail;

[0032] like figure 2 As shown, a refractory iron ore dry grinding-suspension roasting integrated device includes: roller press, dry ball mill or vertical mill, indirect heat exchanger, raw material cyclone collector, suspension magnetization roasting main furnace, roasted ore cyclone Collector, magnetized roaster, suspended bed superheater, front evaporator, fluidized bed indirect heat exchanger, gas combustion system, bag filter, exhaust fan, chimney, dust cyclone collector; the exit of roller press 1 passes through The transport belt is connected to the raw material inlet of the dry ball mill or vertical mill 2; the outlet of the dry ball mill or vertical mill 2 is connected to the inlet of the raw material cyclone collector 3 through a pneumatic conveying pipeline; the raw material outlet of the raw material cyclone collector 3 is passed through the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com