A method for preparing ultra-fine iron powder by low-temperature hydrocarbon double reduction

An ultra-fine iron powder and hydrocarbon technology, applied in the field of powder metallurgy preparation, can solve the problems of low hydrogen conversion rate and high hydrogen consumption, and achieve the effects of low reaction temperature, low production cost and reduced preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

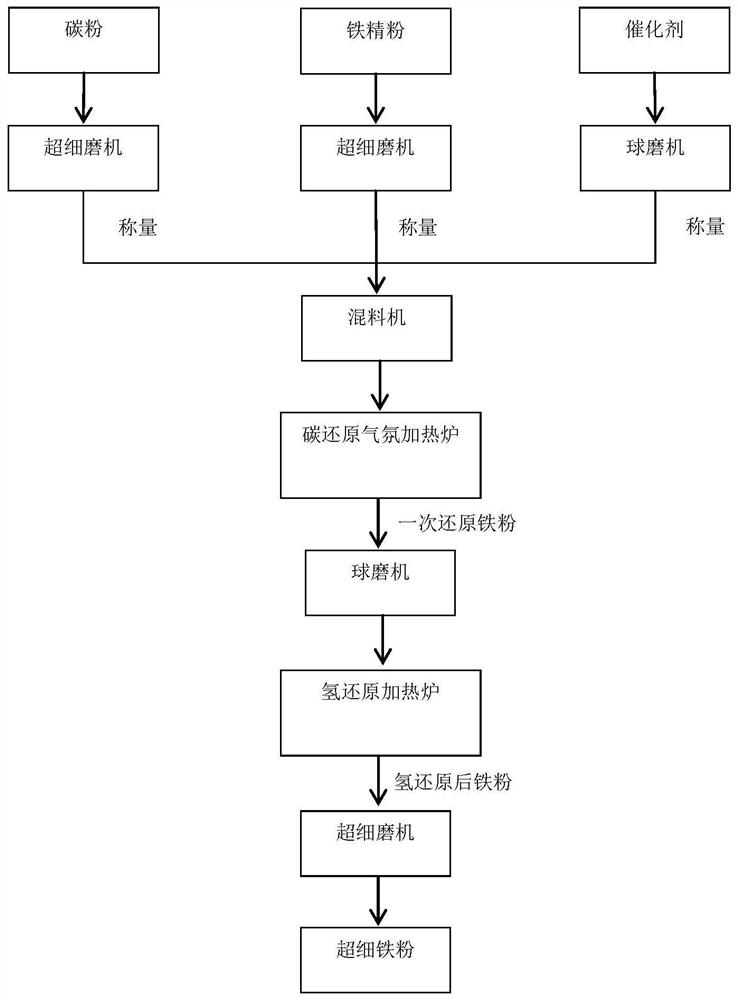

[0058] The preparation method of ultra-fine iron powder proposed in the present invention combines the advantages of gas-based reduction method, carbothermal reduction and ball milling method. Iron oxide is a brittle substance, while iron powder is a plastic substance, so iron oxide is easier to break to the micron level . It can be seen from the kinetics that the finer the particle size, the faster the reaction speed or the lower the required reaction temperature. Therefore, the carbothermal reduction temperature of the ultrafine iron ore concentrate powder of the present invention is only 800-850 ° C. At this temperature, the reaction iron Grains are not easy to grow. If the reaction temperature is too high, the iron powder is easily sintered into hard lumps, and ultrafine iron powder cannot be obtained. The reduction time of 2 to 3 hours is more suitable. When the thickness of the material is thin, the reduction time should be shorter, and vice versa. If the reduction tim...

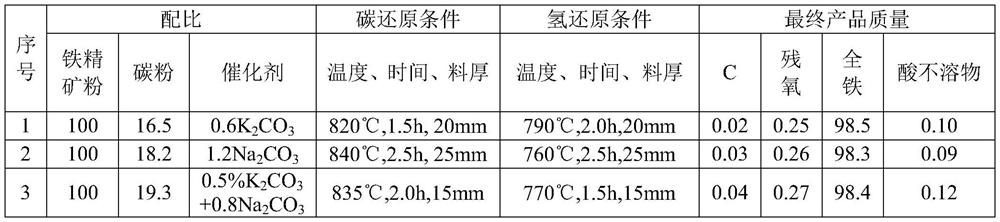

Embodiment 1

[0082] Iron concentrate powder, carbon powder and catalyst K 2 CO 3 The mass ratio of ingredients is 100:16.5:0.6; the temperature for carbon reduction is 820°C, the heating time is 1.5h, and the thickness of the material is 20mm; the temperature for hydrogen reduction is 790°C, the heating time is 2.0h, and the thickness of the material is 20mm ; In the final superfine iron powder product, the total iron content is 98.5%, the C content is 0.02%, the residual oxygen content is 0.25%, and the acid insoluble content is 0.1%.

Embodiment 2

[0084] Iron concentrate powder, carbon powder and catalyst Na 2 CO 3 The mass ratio of ingredients is 100:18.2:1.2; the temperature for carbon reduction is 840°C, the heating time is 2.5h, and the thickness of the material is 25mm; the temperature for hydrogen reduction is 760°C, the heating time is 2.5h, and the thickness of the material is 25mm ; In the final superfine iron powder product, the total iron content is 98.3%, the C content is 0.03%, the residual oxygen content is 0.26%, and the acid insoluble content is 0.09%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com