Solid desulfurizer and preparation method thereof

A desulfurizing agent and solid technology, applied in the field of solid desulfurizing agent and its preparation, can solve the problems of low breakthrough sulfur capacity, low selectivity, complicated operation, etc., achieve high breakthrough sulfur capacity, increase reduction temperature, and improve desulfurization activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

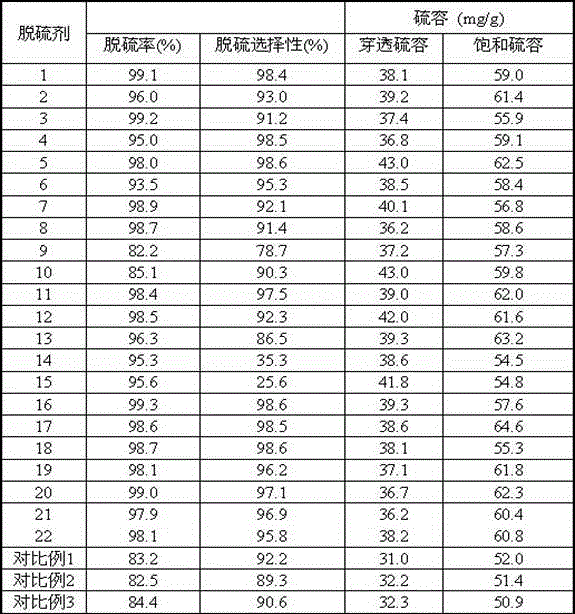

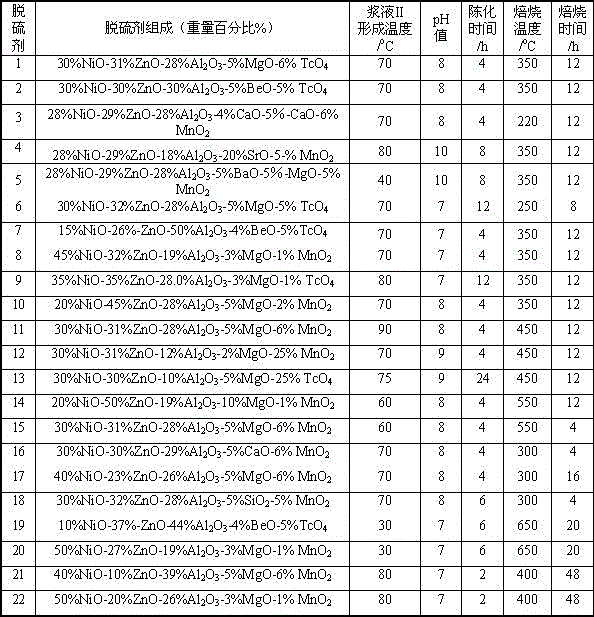

Examples

Embodiment 1

[0019] Preparation of solid desulfurizer 1. 50g aluminum oxide adopts 25g mass percent concentration to be 10% Mg(NO 3 ) 2 The solution is impregnated with equal volume, after drying at 600 o C, calcined to obtain MgO-modified Al 2 o 3 The carrier is to pulverize the desulfurizer precursor I to obtain a 100-200 mesh powder. The pulverized carrier and water are mixed and beaten at room temperature in a ratio of 1:6 by weight to obtain slurry I, and 50 g of nickel nitrate, 40% zinc nitrate and 10% technetium nitrate The mixed solution and 1.0 mol / L sodium carbonate aqueous solution were dropped into slurry I at the same time, and co-precipitated to form slurry II. Precipitation temperature is 70 o C, the pH value of the control solution is 8.0, after the solution is added dropwise, it will be at 70 oC Under aging for 4 hours, then the precipitate was washed and filtered at 120 oC , dry for 12 hours at 350 oC , roasted for 4 hours, and tableted to obtain solid desulfuriz...

Embodiment 2

[0022] Prepare desulfurizer according to each step in Example 1, just change each material composition, preparation condition, make desulfurizer 2, its composition is calculated as 30%NiO-30%ZnO-30%Al by weight percentage 2 o 3 -5%BeO-5%TcO 4 , wherein the preparation conditions and material composition of the desulfurizer are shown in Table 1; the evaluation conditions are the same as in Example 1, and the evaluation results are shown in Table 2.

Embodiment 3

[0024] Prepare desulfurizing agent according to each step in Example 1, just change each material composition, preparation condition, make desulfurizing agent 2, its composition is calculated as 28%NiO-29%ZnO-28%Al by weight percentage 2 o 3 -4%CaO-5%-CaO-6%MnO 2 , wherein the preparation conditions and material composition of the desulfurizer are shown in Table 1; the evaluation conditions are the same as in Example 1, and the evaluation results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com