Adsorption agent for reducing sulphur content of catalytic cracking production

A catalytic cracking and adsorbent technology, applied in the petroleum industry, refined hydrocarbon oil, etc., can solve the problems of limited sulfur content reduction, low sulfur content reduction, etc., and achieve sulfur content reduction, high desulfurization capacity, and low sulfur content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation of carrier sol of the present invention is as follows:

[0041] The main raw materials of the carrier used in this embodiment are as follows:

[0042] 1 # Carrier: 10 kilograms of pseudo-boehmite (solid content is 64% by weight, industrial product of Shandong Zibo Aluminum Factory, the same below);

[0043] 2 # Carrier: 10 kg of pseudo-boehmite+1.0 kg of silica sol (solid content is 25% by weight, produced by Qingdao Lifan Chemical Factory, the same below);

[0044] 3 # Carrier: 4 kilograms of pseudo-boehmite+6 kilograms of kaolin (solid content is 73% by weight, produced by Suzhou China Clay Company);

[0045] 4 # Carrier: 5 kg of pseudoboehmite + 5.2 kg of silica sol + 0.1 kg of hydrated zirconium oxychloride (35% by weight of zirconium oxychloride, produced by Shandong zirconium oxychloride factory);

[0046] 5 # Carrier: 8 kg of 13X powdered molecular sieve (silicon-aluminum ratio of 2.6 to 3.0, produced by Wuxi Rongdeli Molecular Sieve Factor...

Embodiment 1~4

[0050] Examples 1-4 illustrate the composition and preparation method of the adsorbent with a single metal oxide as the active component.

[0051] Weigh commercially available Zn(NO 3 ) 2 6.98 kg, Mn(CH 3 COO) 2 2.74 kg, CuSO 4 0.50 kg with FeCl 2 0.13 kg, each made into an aqueous solution with a metal ion concentration of 8mol / L, add ammonia water with a concentration of 4mol / L at room temperature, maintain pH = 8-9, stir continuously until the precipitation is complete, then raise the temperature to 70°C and place it for aging for 0.5 Hour. Filtrate, wash the filter cake until there is no acid ion, and obtain precipitates of Zn, Mn, Cu and Fe metal hydroxides respectively.

[0052] Use 4 kg of decationized water to beat the precipitate of the above-mentioned metal hydroxide, then add 20 kg of one of the above-mentioned carrier sols and stir evenly, leave it to age at 75°C for 1 hour, and keep the pH=2~4, Cool down to 60°C, spray dry and shape, wash to remove free Na...

Embodiment 5~8

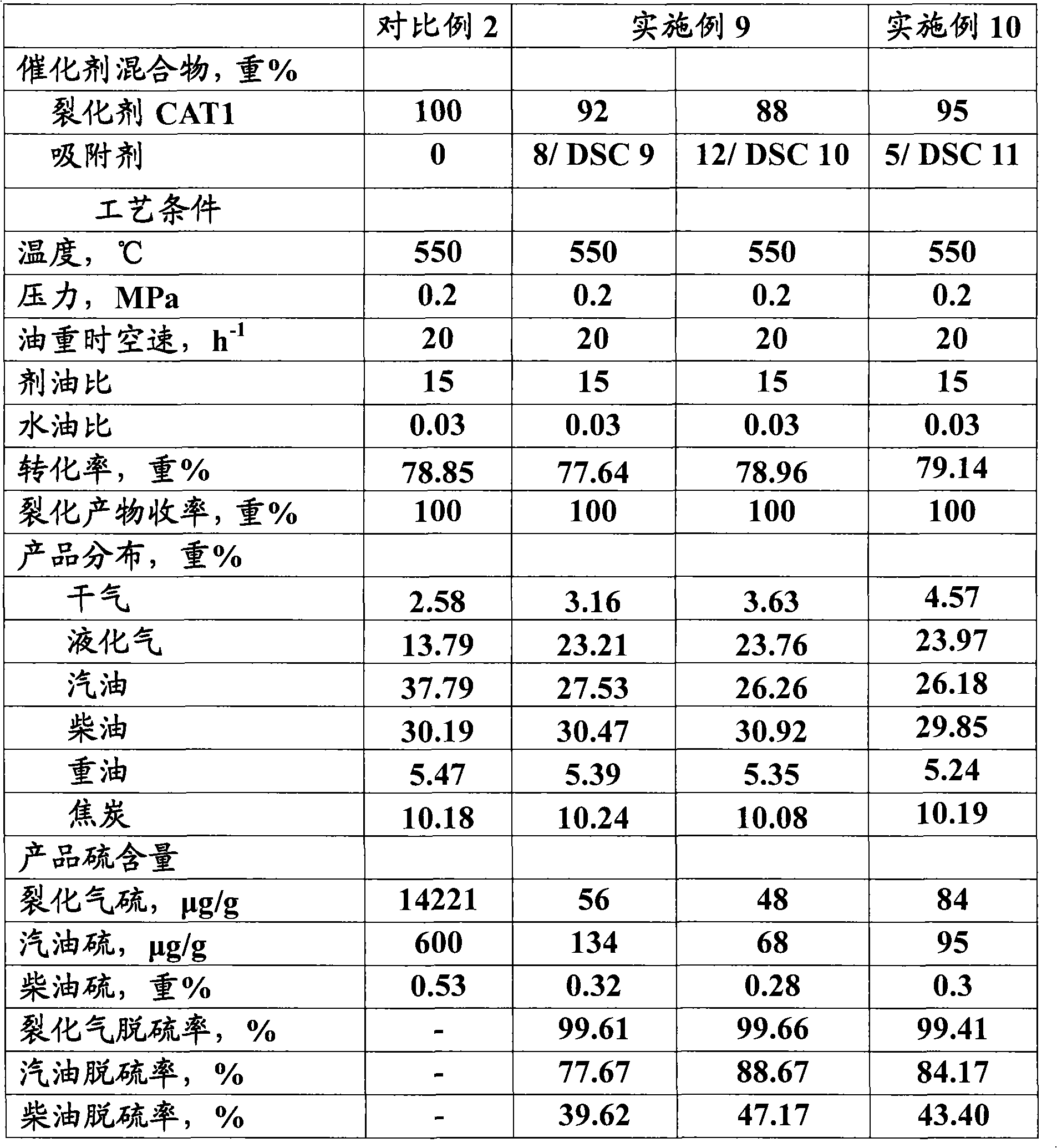

[0055] Examples 5-8 illustrate the composition, preparation method and application of the adsorbent with two kinds of metal oxides as active components.

[0056] Cu(NO 3 ) 2 with Mn(NO 3 ) 2 , Cu(NO 3 ) 2 with Fe(NO 3 ) 3 , Fe(NO 3 ) 3 with Mn(NO 3 ) 2 , Fe(NO 3 ) 3 with Zn(NO 3 ) 2 Weigh 3.74, 2.79, 2.91, and 1.62 kg of the mixture according to the metal molar ratios of 0.1:1, 0.5:1, 1:1, and 5:1, respectively, and make an aqueous solution with a metal ion concentration of 4mol / L, and add a concentration of 2mol / L ammonia water, maintain pH = 9, keep stirring until the precipitation is complete, then raise the temperature to 80°C and leave it to age for 2 hours. Filtrating and washing the filter cake until there is no acid ion to prepare Cu-Mn, Cu-Fe, Fe-Mn and Fe-Zn double metal hydroxide mixtures respectively.

[0057] Use 7 kg of decationized water to beat the mixture of the above-mentioned double hydroxides, then add 20 kg of one of the above-mentioned car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com