Method of treating weave printing and dyeing wastewater by slurries production technology

A technology for textile printing and dyeing and production process, applied in the field of textile printing and dyeing wastewater treatment, can solve problems such as restricting the expansion of production capacity of textile printing and dyeing enterprises, not yet realizing comprehensive utilization, wasting water resources, etc., achieving low wastewater treatment costs, reducing pulping costs, The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

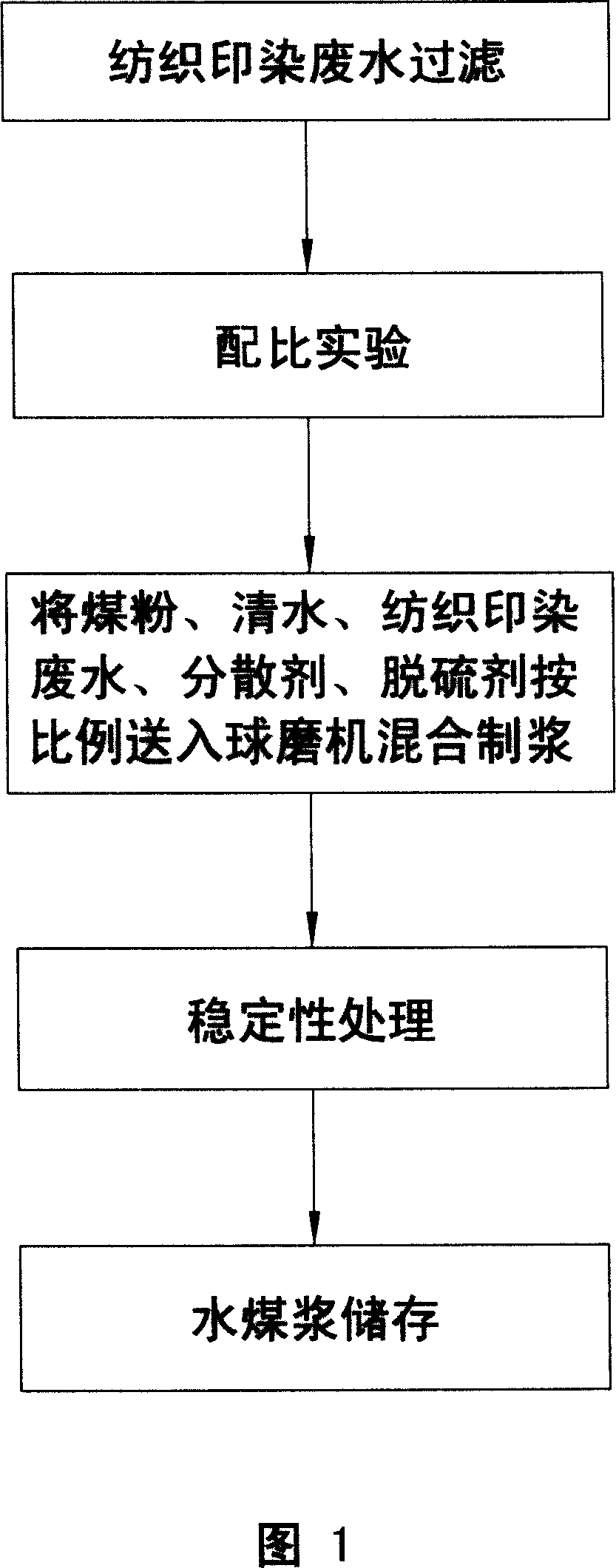

[0018] The method that present embodiment utilizes coal-water slurry production process to process textile printing and dyeing wastewater comprises the following steps:

[0019] (a) Filtration step: filter textile printing and dyeing wastewater to remove impurities with larger particle sizes, and the filtered residue can be disposed of by burning, landfilling, etc.;

[0020] (b) Proportioning step: take a sample from the filtered textile printing and dyeing wastewater, mix it with clear water in a ratio of 1:1, then add lignosulfonate as a dispersant, and then gradually add lime water (i.e. Ca(OH) 2 Solution) as a desulfurizing agent until the pH value of the sample is equal to 8, the pH range after the proportioning can be between 8 and 10, that is, it only needs to be weakly alkaline, so that the effect of removing sulfur in the coal can be achieved. In this step, the ratio relationship among desulfurizer, dispersant, clear water, and textile printing and dyeing wastewater c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com