Method for removing sulfide in simulated oil through oxidation by using transition metal tungstate as catalyst

A transition metal and tungstate technology, which is applied in the refining of oxygen-containing compounds, etc., can solve the problems of limited application and difficult recovery, and achieve the effects of easy recovery, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

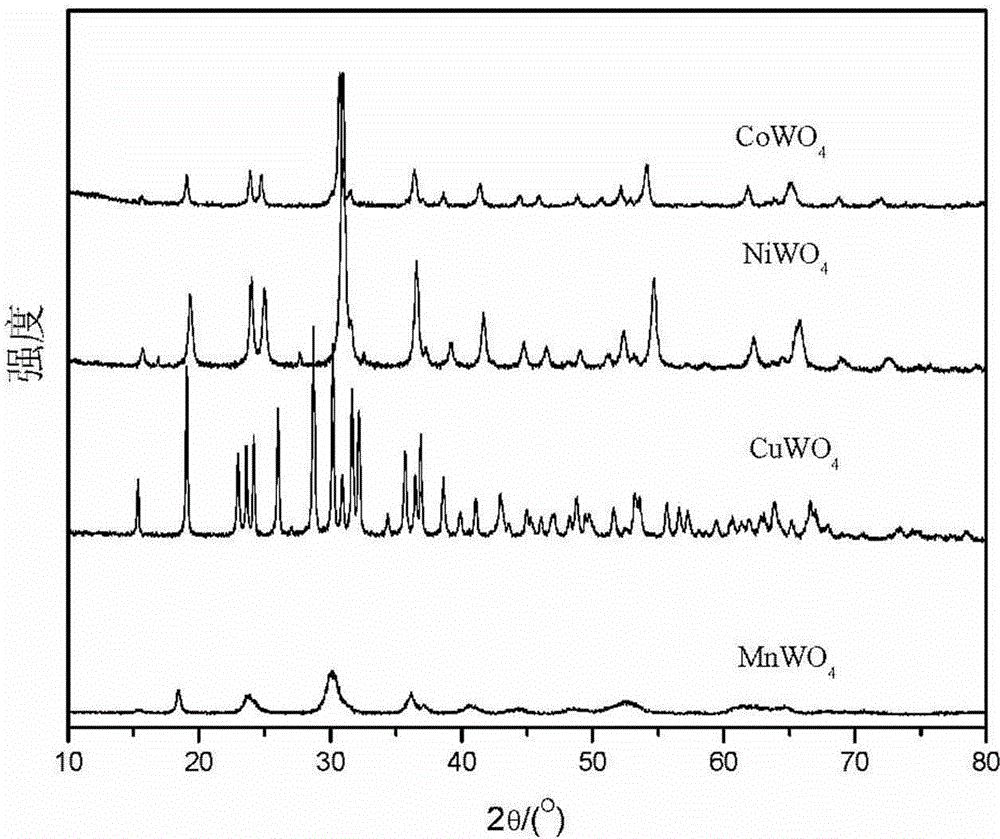

[0021] Transition metal tungstates include the following: CuWO 4 , NiWO 4 , CoWO 4 , MnWO 4 , 4 kinds of tungstate reference [U.M. García-Pérez, A. Martínez-de la Cruz, J. Peral. Transition metal tungstates synthesized by co-precipitation method: Basic photocatalytic properties[J]. Electrochimica Acta, 2012, 81: 227-232].

[0022] A. Synthesis of transition metal nickel tungstate.

[0023] The specific preparation process is as follows: Weigh a certain mass of transition metal nickel nitrate, dissolve it in water, add sodium tungstate, stir at room temperature for 3 hours, collect the product and wash it with water and dry it at 70°C for 6 hours, and then put the product in a muffle furnace for 500 Calcined at ℃ for 4h.

[0024] B. Simulate oil desulfurization.

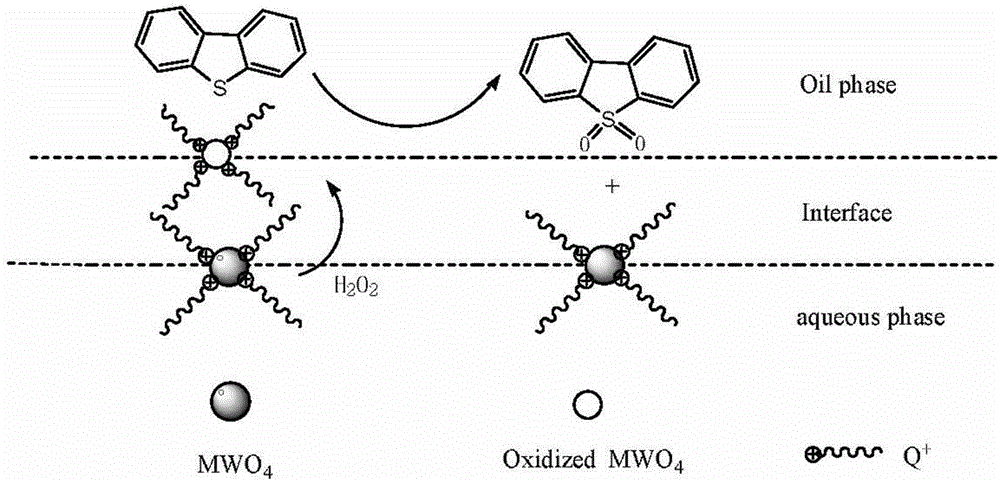

[0025] Add 0.01g of nickel tungstate to 10 mL of simulated oil with a sulfur content of 500 μg / g prepared by a certain amount of dibenzothiophene (DBT), add 0.2mL of H 2 o 2 and 0.01g of cetyltrimethylammon...

Embodiment 2

[0029] A. Synthesis of transition metal cobalt tungstate.

[0030] The specific preparation process is as follows: Weigh a certain mass of transition metal cobalt nitrate salt, dissolve it in water, add sodium tungstate, stir at room temperature for 2 hours, collect the product and wash it with water and dry it at 75°C for 6 hours, and then put the product in the muffle furnace Calcined at 500°C for 4h.

[0031] B. Simulate oil desulfurization.

[0032] Add 0.01g cobalt tungstate to 10 mL simulated oil with a sulfur content of 500 μg / g prepared by a certain amount of dibenzothiophene (DBT), add 0.2 mL H 2 o 2 , after reacting at 30°C for 30 min in a constant temperature water bath equipped with magnetic stirring, the reaction mixture was cooled to room temperature, and the layers were separated in a separatory funnel to separate the oil phase. Add 5 mL of N-N-dimethylformamide and continue to stir for 10 min, statically separate layers, separate the oil phase, measure the ...

Embodiment 3

[0036] Add 0.01g manganese tungstate to 10 mL simulated oil with a sulfur content of 500 μg / g prepared by a certain amount of dibenzothiophene (DBT), add 0.2 mL H 2 o 2 , after reacting at 30°C for 30 min in a constant temperature water bath equipped with magnetic stirring, the reaction mixture was cooled to room temperature, and the layers were separated in a separatory funnel to separate the oil phase. Add 5 mL of N-N-dimethylformamide and continue to stir for 10 min, statically separate layers, separate the oil phase, measure the sulfur content and calculate the desulfurization rate to be 89%.

[0037] The synthesis steps and recovery steps of the transition metal manganese tungstate are the same as above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com