An upward-sloping trapezoidal wave interface device for a three-swirl biomass gasification burner

An interface device and trapezoidal wave technology, which is used in combustion equipment, combustion of solid fuel, and the manufacture of combustible gas, etc., can solve the problems of insufficient combustion of gas and high air intake rate of air inlet pipe.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

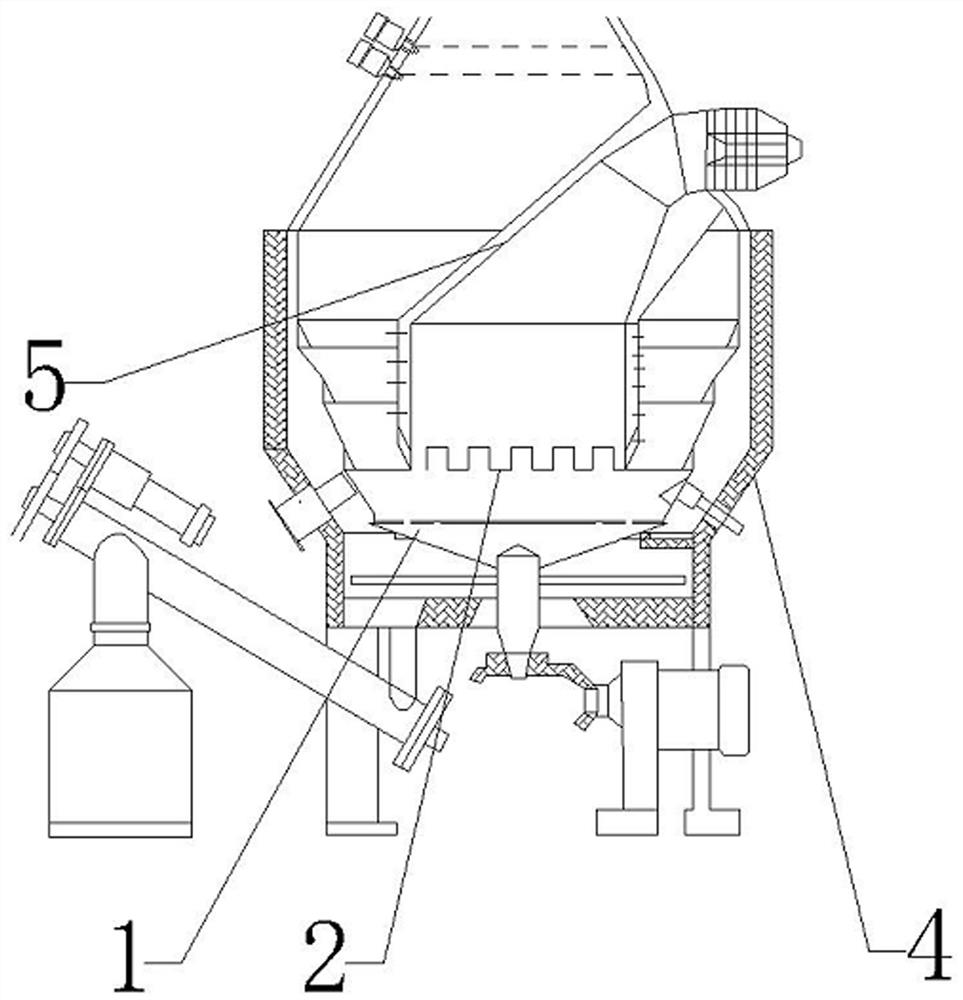

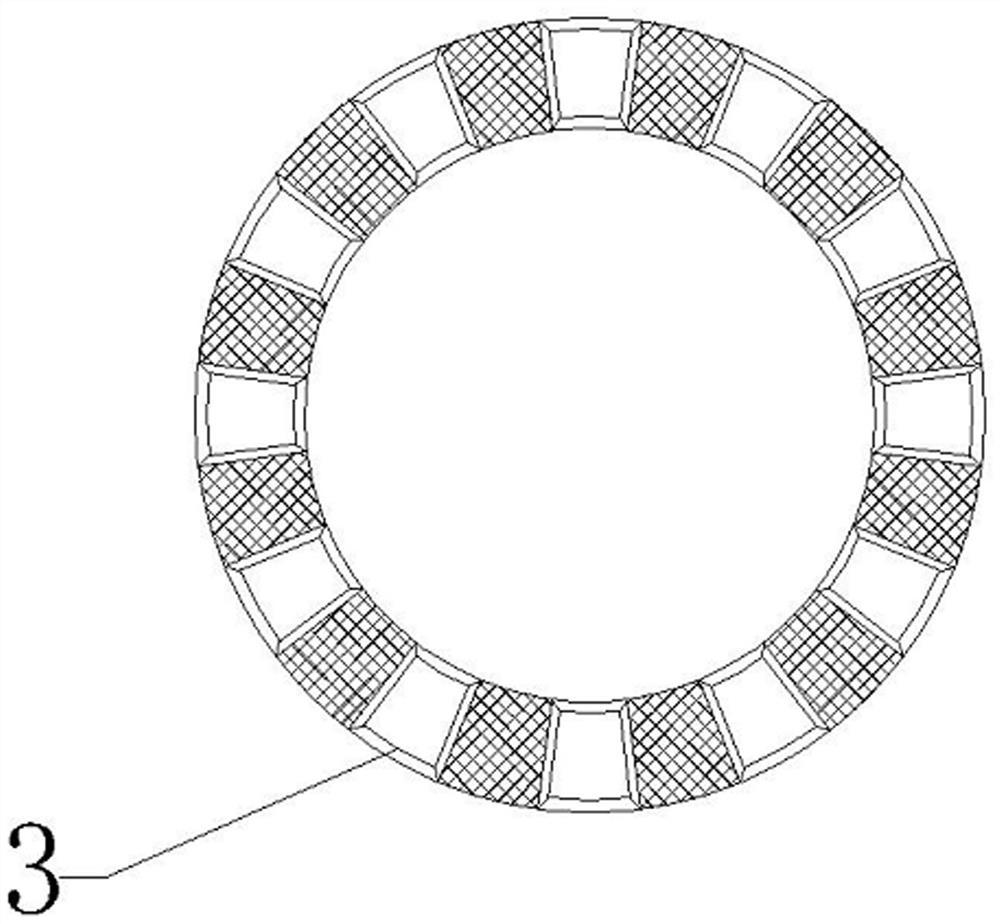

[0017] An upward-sloping trapezoidal wave interface device for a three-swirl biomass gasification burner, which is mainly composed of an annular trapezoidal wave interface and a narrowing-shaped reducing chamber, and the narrowing-shaped reducing chamber is inserted obliquely from the right side into the furnace body Among them, the annular trapezoidal wave interface is connected and fixed at the center position above the grate, and the annular trapezoidal wave interface is fixed at the bottom of the shrinking reduction chamber, wherein, the bottom of the annular trapezoidal wave interface is uniformly distributed with a narrow lower part and a wider outer part. Wide and narrow trapezoidal openings, the trapezoidal openings are evenly distributed at the bottom of the annular trapezoidal wave interface. The application method of the upward inclined trapezoidal wave interface device for a three-swirl biomass gasification burner is: during use, the furnace body The grate at the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com