Roasting method of efficiently controlling iron ores to be magnetized

An iron ore, high-efficiency technology, applied in the field of roasting that efficiently controls the magnetization of iron ore, can solve the problems of long reduction time, poor uniformity, and high content of harmful gases, and achieve improved diffusion and thermal conductivity, good reduction temperature, and elimination of pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

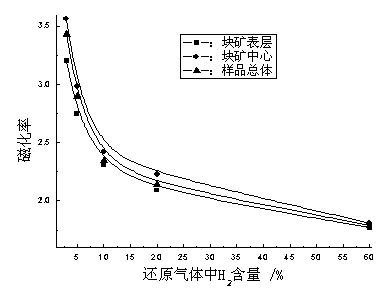

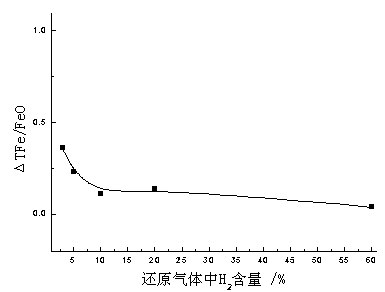

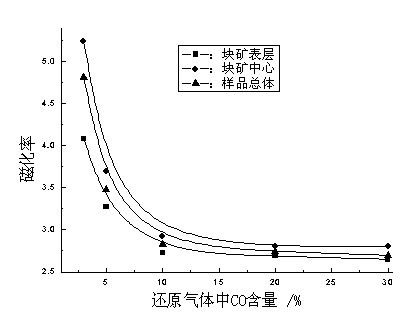

[0026] A roasting method for efficiently controlling the magnetization of iron ore, the first step is limonite mFe 2 O 3 .nH 2 O is added from the top of the shaft furnace by the distributor of the shaft furnace, limonite mFe 2 O 3 .nH 2 O particle size is 15mm; in the second step, the iron ore passes through the preheating section of the shaft furnace for drying and preheating; in the third step, the iron ore passes through the heating section of the shaft furnace for heating and heating at the burner of the shaft furnace; In the fourth step, the iron ore is reduced through the reduction section of the shaft furnace with the reduction gas sprayed from the reduction gas ejection tower of the shaft furnace; the reduction temperature is 720℃, the reduction time is 1h, and the reduction gas is CO and H 2 The mixed gas, which reduces the H in the gas 2 The volume fraction is 15%, and the flow rate of the reducing gas sprayed from the reducing gas outlet tower is 1200m 3 / h, the pressu...

Embodiment 2

[0028] A roasting method for efficiently controlling the magnetization of iron ore, the first step is hematite Fe 2 O 3 Add from the top of the shaft furnace by the distributor of the shaft furnace, hematite Fe 2 O 3 The particle size is 100mm; in the second step, the iron ore passes through the preheating section of the shaft furnace for drying and preheating; in the third step, the iron ore passes through the heating section of the shaft furnace for heating and heating at the burner of the shaft furnace; Step, the iron ore is reduced through the reduction section of the shaft furnace with the reduction gas sprayed from the reduction gas ejection tower of the shaft furnace; the reduction temperature is 700℃, the reduction time is 1.25h, and the reduction gas is CO and H 2 The mixed gas, which reduces the H in the gas 2 The volume fraction is 18%, and the flow rate of the reducing gas sprayed from the reducing gas outlet tower is 1000m 3 / h, the pressure of the sprayed reducing g...

Embodiment 3

[0030] A roasting method for efficiently controlling the magnetization of iron ore, the first step is hematite Fe 2 O 3 Add from the top of the shaft furnace by the distributor of the shaft furnace, hematite Fe 2 O 3 The particle size is 100mm; in the second step, the iron ore passes through the preheating section of the shaft furnace for drying and preheating; in the third step, the iron ore passes through the heating section of the shaft furnace for heating and heating at the burner of the shaft furnace; Step, the iron ore is reduced through the reduction section of the shaft furnace with the reduction gas sprayed from the reduction gas ejection tower of the shaft furnace; the reduction temperature is 680℃, the reduction time is 1.5h, and the reduction gas is CO and H 2 The mixed gas, which reduces the H in the gas 2 The volume fraction is 12%, and the flow rate of the reducing gas sprayed from the reducing gas outlet tower is 1100m 3 / h, the pressure of the sprayed reducing gas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com