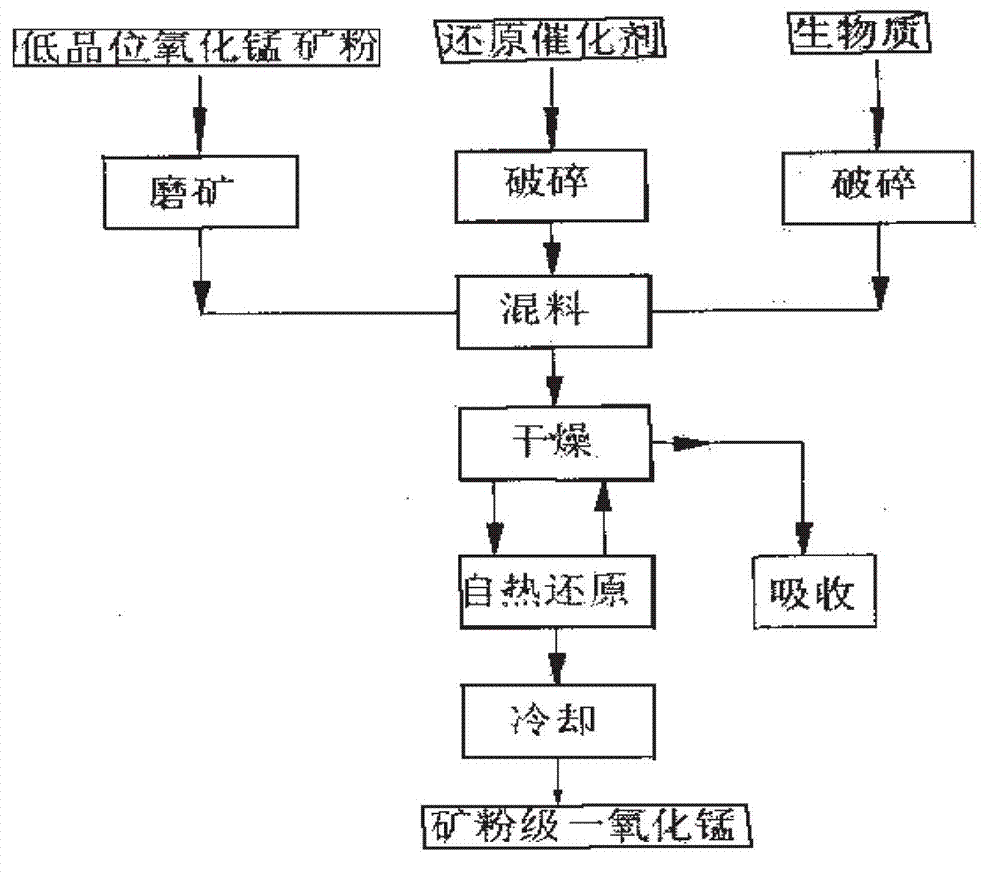

Device and process for producing manganese monoxide through reduction of low-grade manganese oxide ore by using biomass

A manganese oxide ore, manganese monoxide technology, applied in manganese oxide/manganese hydroxide and other directions, can solve the problems of no process equipment, high production cost, high reduction temperature, high production cost, reduced biomass consumption, and large energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

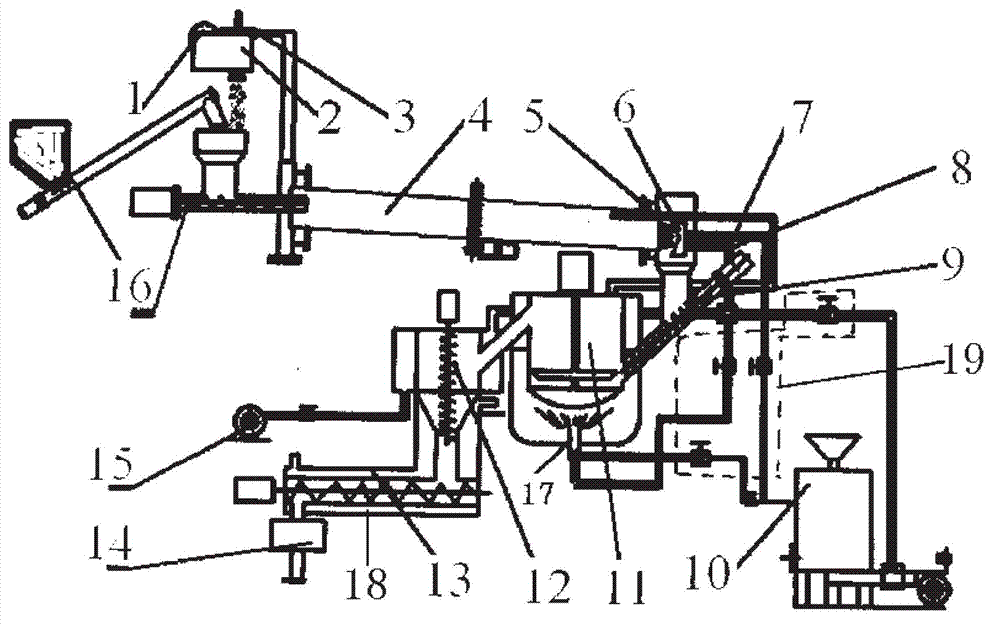

[0023] The invention provides equipment and a process for producing ore-grade manganese monoxide by reducing low-grade manganese oxide ore with biomass. The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited in any way.

[0024] figure 2 Shown is the process equipment for reducing manganese dioxide to manganese monoxide with biomass. In the figure, the rotary kiln 4 is provided with a feeding screw propeller 16, and the tail of the rotary kiln 4 is provided with a biomass gas burner 6. The reaction furnace propeller 9 is connected to the reaction furnace 11, the reaction furnace 11 is connected to the simmering tank 12, a stirring device is arranged in the reaction furnace 11, the reaction furnace 11 is connected to the reaction furnace return heat pipe 8; the simmering tank 12 is connected to the spiral cooler 13 Connected, a water shower 14 and a circulating water pump 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com