Technological method for improving TiO2 grade of synthetic rutile by reduction rust method

A technology of artificial rutile and process method, applied in chemical instruments and methods, titanium oxide/hydroxide, inorganic chemistry, etc., can solve problems such as insufficiency, achieve low cost, improve TiO2 grade, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

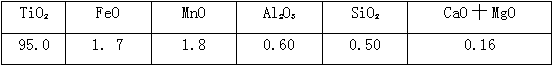

Embodiment 1

[0025] This embodiment selects seashore placer titanium concentrate 1#, its main component TiO 2 is 56.00%.

[0026] Step 1: Pass it through 800GS, 8000GS cascade magnetic separation and 20,000-volt high-voltage electric separation to discharge magnetite, low-grade titanium concentrate, non-magnetic ore, weak magnetic titanium ore and garnet in titanium concentrate and Titanium concentrate is magnetically close to the impurity ore to obtain high-grade, high-purity titanium concentrate raw materials.

[0027] Step 2: put the above-mentioned titanium concentrate into the rotary kiln for high temperature and negative pressure sealed reduction, control the reduction temperature at 1180°C, and the metallization rate of iron oxide is 90%.

[0028] Step 3: Pass the high-temperature material from the reduction kiln through the heat exchanger to generate high-temperature steam into the corrosion tank, keep the corrosion reaction temperature at 80°C, and control the metal iron content ...

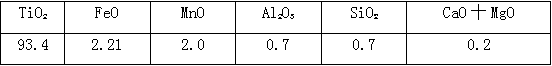

Embodiment 2

[0036] This embodiment selects seashore placer titanium concentrate 2#, its main component TiO 2 is 58.00%.

[0037] Step 1: Pass it through 900GS, 8000GS cascade magnetic separation and 25,000-volt high-voltage electric separation to discharge magnetite, low-grade titanium concentrate, non-magnetic ore, weak magnetic titanium ore and garnet in titanium concentrate and Titanium concentrate is magnetically close to the impurity ore to obtain high-grade, high-purity titanium concentrate raw materials.

[0038] Step 2: Put the above-mentioned titanium concentrate into the rotary kiln for high-temperature negative pressure sealed reduction, control the reduction temperature at 1200°C, and the metallization rate of iron oxide is 92%.

[0039] Step 3: Pass the high-temperature material from the reduction kiln through the heat exchanger to generate high-temperature steam into the corrosion tank, keep the corrosion reaction temperature at 85°C, and control the metal iron content to 0...

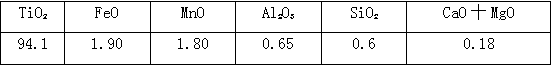

Embodiment 3

[0047] This embodiment selects seashore placer titanium concentrate 3#, its main component TiO 2 is 60.00%.

[0048] Step 1: Pass it through 1000GS, 9000GS cascade magnetic separation and 30,000 volt high-voltage electric separation to discharge magnetite, low-grade titanium concentrate, non-magnetic ore, weak magnetic titanium ore and garnet in titanium concentrate and Titanium concentrate is magnetically close to the impurity ore to obtain high-grade, high-purity titanium concentrate raw materials.

[0049] Step 2: put the above-mentioned titanium concentrate into the rotary kiln for high-temperature negative pressure sealed reduction, control the reduction temperature at 1250°C, and the metallization rate of iron oxide is 93%.

[0050]Step 3: Pass the high-temperature material from the reduction kiln through the heat exchanger to generate high-temperature steam into the corrosion tank, keep the corrosion reaction temperature at 90°C, and control the metal iron content to 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com