Microwave-fuel combined heating-type coal-based direct reduction method and rotary hearth furnace

A combined heating and rotary hearth furnace technology, applied in the field of rotary hearth furnaces and coal-based direct reduction rotary hearth furnaces, can solve the impact of microwave device maintenance costs on production, operation and economics, investment can not be afforded by enterprises, and there is no Through any research and other issues, to achieve the effect of industrialization and market promotion and application, easy realization and promotion and application, and speeding up the gasification reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

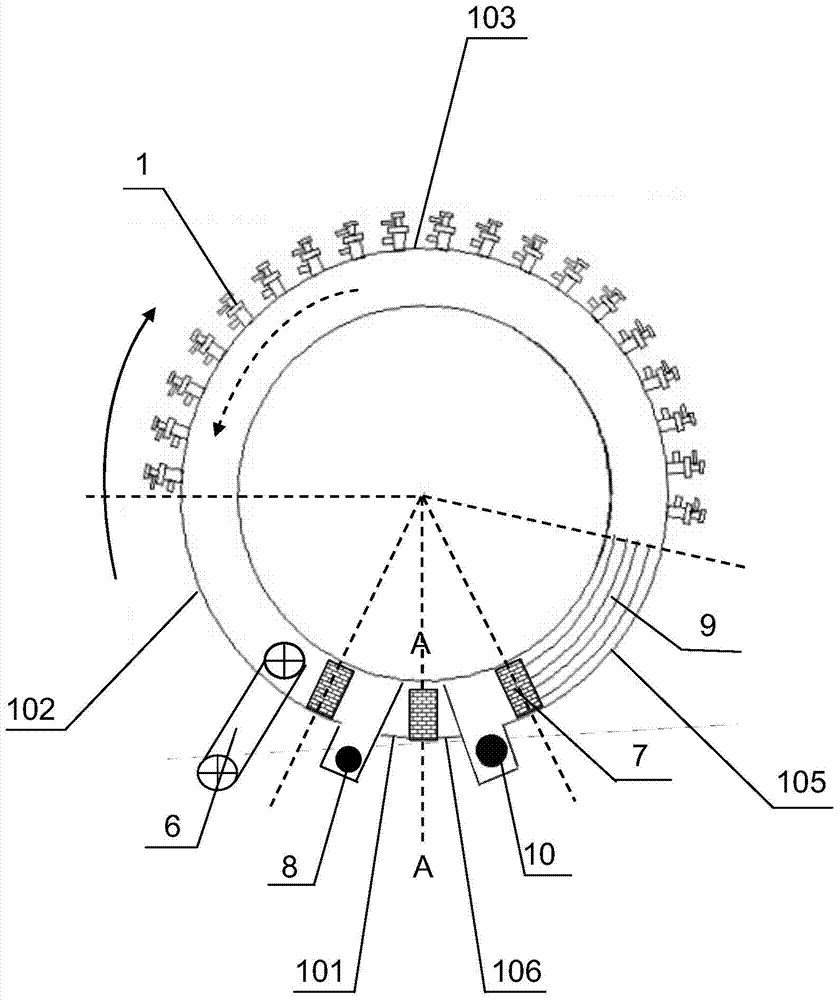

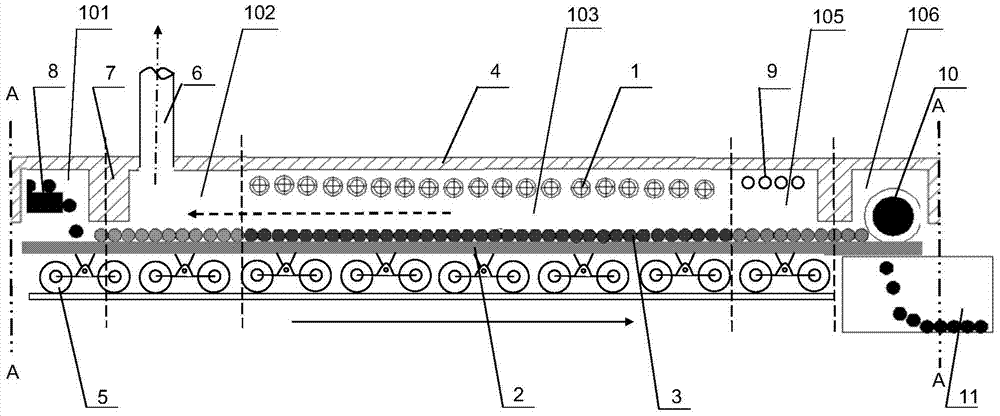

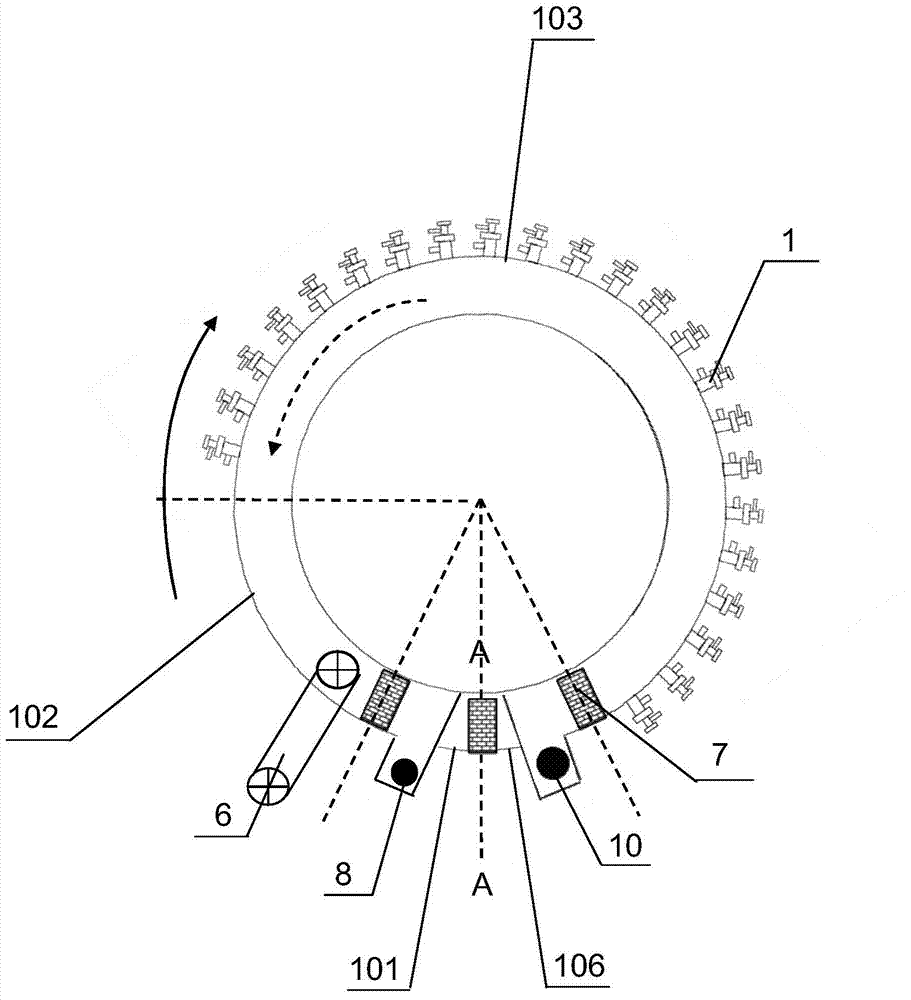

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0044] Electromagnetic performance is the internal factor that reflects the coupling ability of materials and microwaves. The electromagnetic properties of materials determine the microwave heating characteristics of materials and are the foundation of whether materials can be heated by microwaves. Starting from the electromagnetic properties of the material itself, to study the ability of the material to absorb microwaves, the main factors to be investigated are the complex permittivity of the material (the real part of the permittivity ε′ r and the imaginary part ε″ r ), because in the microwave electromagnetic field, the main factor affecting the temperature rise of the material is the dielectric loss. However, the electromagnetic properties of materials will also change greatly with changes in temperature, phase and structure. L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com