Highly dispersed palladium/carbon nanometer tube catalyst for anthraquinone hydrogenation and preparation method thereof

A technology of carbon nanotubes and catalysts, which is applied in the field of highly dispersed palladium/carbon nanotube catalysts and its preparation, can solve the problems of unsatisfactory reduction effect of palladium active components, insignificant catalyst effect, and small amount of reducing agent, etc., to achieve improved Effective utilization rate, improved hydrogenation efficiency, and easy recovery of palladium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

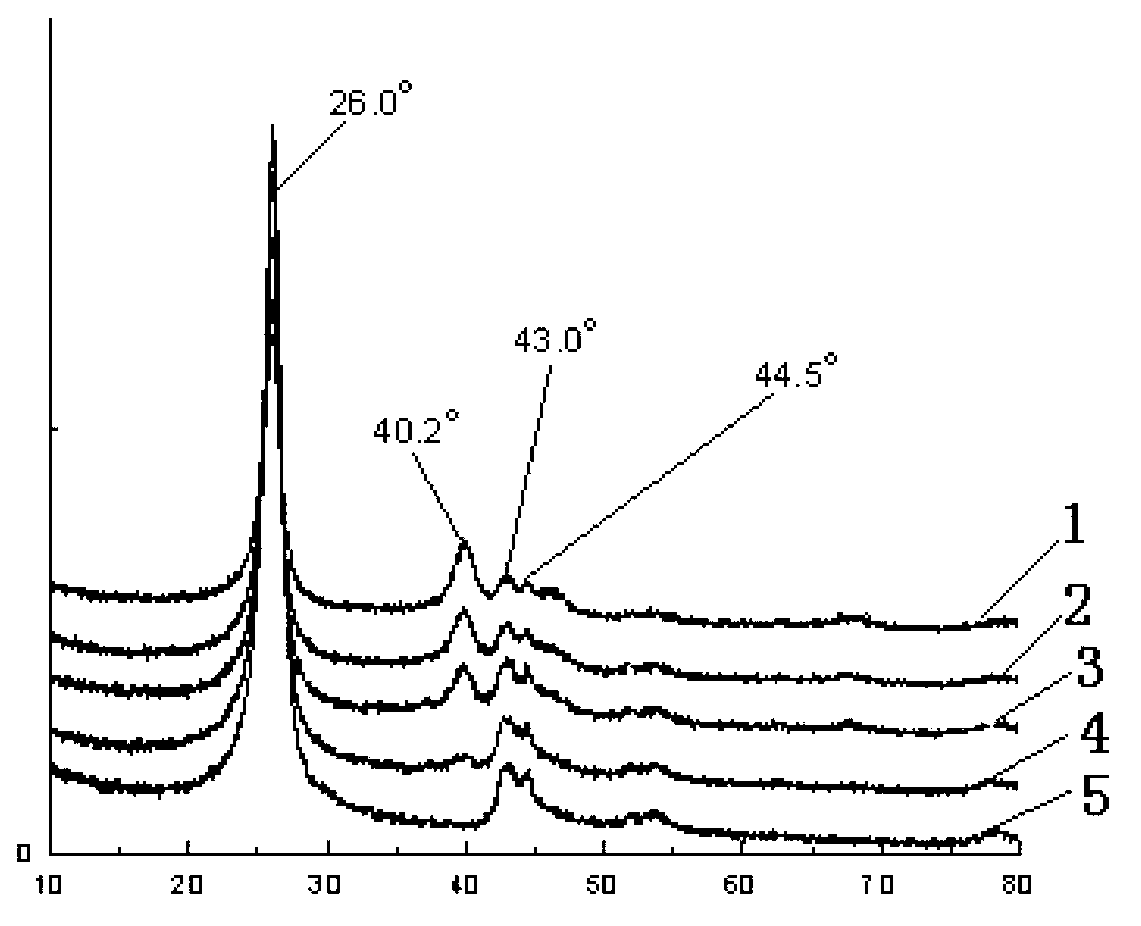

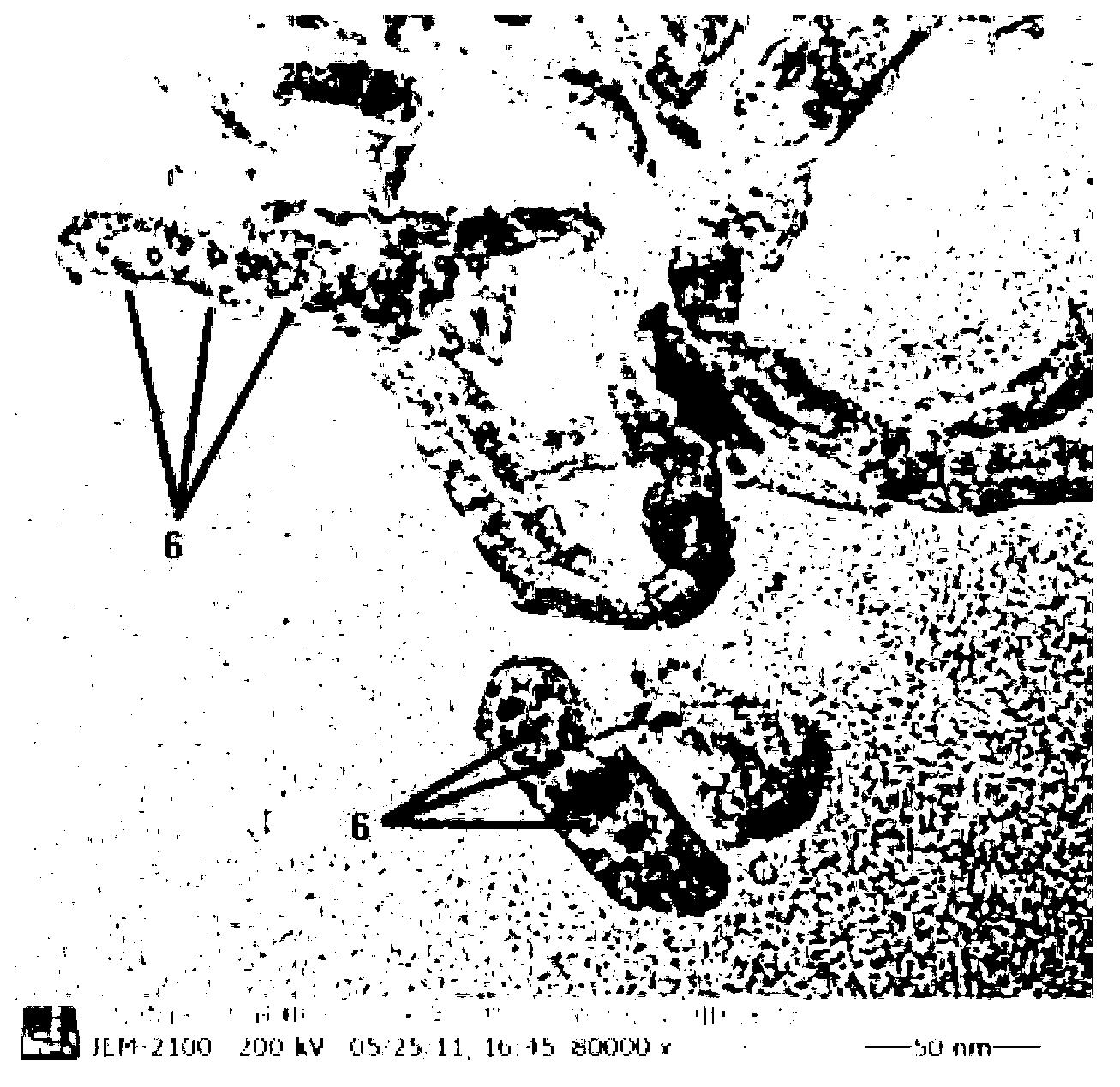

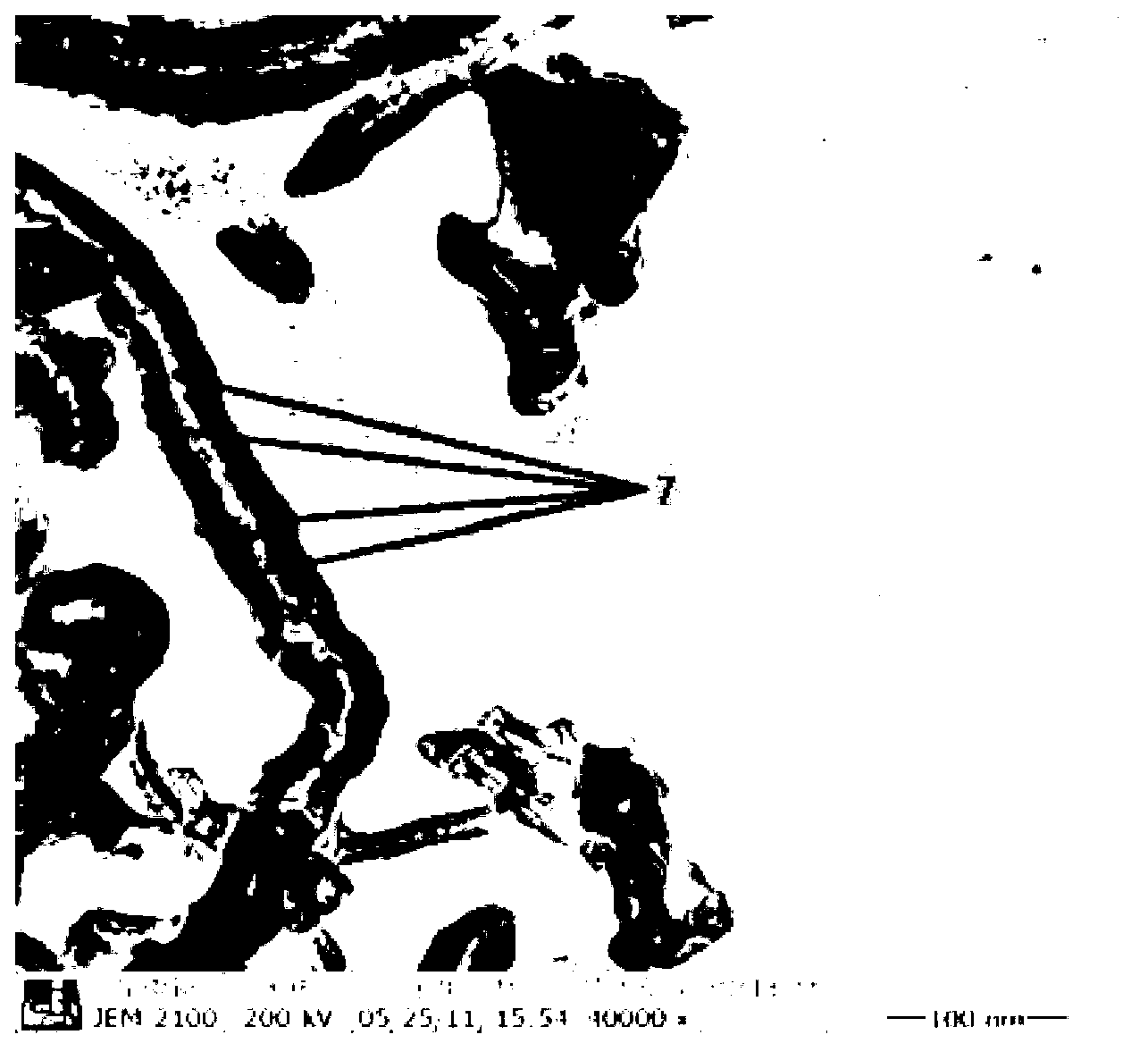

Embodiment 1

[0062] In the slurry bed of the reaction vessel, add carbon nanotubes and water according to the mass ratio of CNTs (carbon nanotubes): water = 1:45, stir mechanically and ultrasonically until the carbon nanotubes are uniformly dispersed, and prepare a carbon nanotube suspension. After 20 minutes, keep mechanical and ultrasonic stirring, slowly add palladium chloride hydrochloric acid with an appropriate concentration of 0.25g / L to the carbon nanotube suspension according to the loading of Pd (nano-palladium particles) being 0.28wt% of the carbon nanotubes Solution, obtain palladium ion / carbon nanotube suspension, after 20 minutes, add the NaOH alkaline solution of 15wt% to adjust the pH of palladium ion / carbon nanotube suspension to be 9~12, continue to keep mechanical and ultrasonic stirring, be warming up to 40 ℃ and add excess formaldehyde solution, and continue to adjust with NaOH solution and keep the pH at 10~14 until the pH is basically unchanged within 30min, filter, w...

Embodiment 2

[0072] In the slurry bed of the reaction vessel, add carbon nanotubes and water according to the mass ratio of CNTs (carbon nanotubes): water = 1:45, stir mechanically and ultrasonically until the carbon nanotubes are uniformly dispersed, and prepare a carbon nanotube suspension. After 22 minutes, keep mechanical and ultrasonic stirring, slowly add palladium chloride hydrochloric acid with an appropriate concentration of 0.50g / L to the carbon nanotube suspension according to the loading of Pd (nano-palladium particles) being 0.84wt% of the carbon nanotubes Solution, obtain palladium ion / carbon nanotube suspension, after 15 minutes, add the NaOH alkaline solution of 15wt% to adjust the pH of palladium ion / carbon nanotube suspension to be 9~12, keep mechanical and ultrasonic stirring, be warming up to 40 ℃ and add excess formaldehyde solution, and continue to adjust with NaOH solution and keep the pH at 10~14 until the pH is basically unchanged within 30min, filter, wash, and...

Embodiment 3

[0074] In the slurry bed of the reaction vessel, add carbon nanotubes and water according to the mass ratio of CNTs (carbon nanotubes): water = 1:45, stir mechanically and ultrasonically until the carbon nanotubes are uniformly dispersed, and prepare a carbon nanotube suspension. After 26 minutes, keep mechanical and ultrasonic stirring, slowly add palladium chloride hydrochloric acid with an appropriate concentration of 1.0g / L to the carbon nanotube suspension according to the loading of Pd (nano-palladium particles) at 2.52wt% of the carbon nanotubes Solution, obtain palladium ion / carbon nanotube suspension, after 18 minutes, add the NaOH alkaline solution of 15wt% to adjust the pH of palladium ion / carbon nanotube suspension to be 10~11, continue to keep mechanical and ultrasonic stirring, be warming up to 40 ℃ and add excess formaldehyde solution, and continue to use NaOH solution to adjust and keep the pH at 12~14 until the pH is basically unchanged within 30min, filter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com