C5 petroleum resin hydrogenation catalyst and preparation method thereof

A technology of hydrogenation catalyst and petroleum resin, which is applied in the field of hydrogenation of oil products, can solve the problems of difficult reduction of tungsten oxide and reduction of catalyst activity, and achieve the effects of easy peptization, improved carrier strength, and avoiding damage to the pore structure of alumina

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

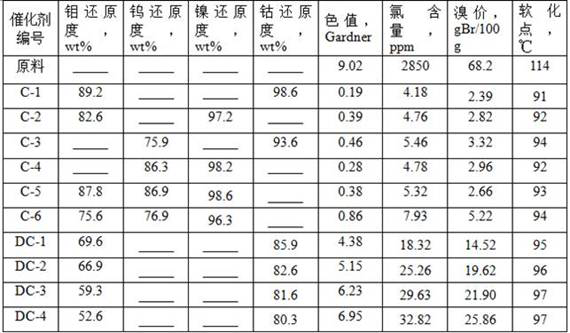

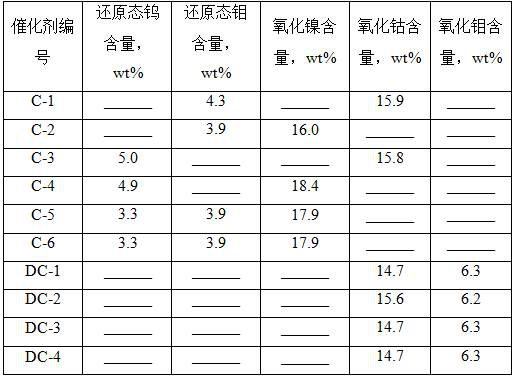

Examples

Embodiment 1

[0029] Aluminum sulfate was dissolved in deionized water, formulated into a solution of 0.5 g / ml of aluminum oxide, and was placed in a 1 L of the aluminum sulfate solution, and then dripped with sodium hydroxide solution, pH is constant to 8.2. After the temperature is 60 ° C, the reaction is completed after 60 min, washed three times with deionized water, then add a quantified deionized water to obtain a solid liquid mass ratio of 10% (in alumina gauge)..

[0030] 20g Y molecular sieve (SIO 2 / Al 2 O 3 The molar ratio is 40.0, the cell constant is 15 å, the relative crystallinity is 90%), and 250 g of anhydrous ethanol, then add 250 g of anhydrous ethanol, stir well, then add 100 g of tetraethoxysilane, After continuous stirring is mixed, then a small amount of tetramethylammonium hydroxide is added to adjust the slurry pH to 9.0. In the closed autoclave, after 190 ° C aging for 20 h, the filtration was taken until the filter cake was 39%, and 11.2 g of ethylenediamine and 12...

Embodiment 2

[0032] Solly molybdate is in deionized water, formulated into MOO 3 A solution of a concentration of 0.12 g / ml, impregnated with a solution of 150 g of a molecular sieve modified alumina support, dried at 200 ° C for 3 h, and then reduced treatment, the reduction conditions were: reduction pressure was 1.5 MPa, and the reduction temperature was 500 ° C , The reduction time is 5 hours, the hydrogen flow is 200ml / min, then in N 2 The atmosphere was reduced to room temperature to obtain a catalyst precursor.

[0033] The cobalt nitrate is soluble in deionized water, and the COO content is 0.5 g / ml impregnation liquid, and 60 mL is impregnated into the catalyst precursor, and then in N 2 The atmosphere was dried at 110 ° C for 3 h, and 2 h was calcined at 300 ° C to obtain catalyst C-1.

Embodiment 3

[0035] Solly molybdate is in deionized water, formulated into MOO 3 A solution of a concentration of 0.11 g / ml, impregnated with 150 g of a molecular sieve modified alumina carrier, dried at 200 ° C for 3 h, then recovered treatment, the reduction conditions were: reduction pressure was 1.5 MPa, and the reduction temperature was 500 ° C , The reduction time is 5 hours, the hydrogen flow is 200ml / min, then in N 2 The atmosphere was reduced to room temperature to obtain a catalyst precursor.

[0036] Nitrate is dissolved in deionized water, and it is equipped with a NiO content of 0.5 g / ml impregnation liquid, and 60 mL is impregnated into the catalyst precursor, and then in N 2 The atmosphere was dried at 110 ° C for 3 h, and 2 h was calcined at 300 ° C to obtain catalyst C-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com