Coal gasification method

A technology for coal gasification and coal gas flow, which is applied in the field of coal gasification technology, can solve the problems of high unconverted carbon content and low operating temperature, and achieve the effects of improving gasification efficiency, increasing gasification temperature, and easily expanding capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

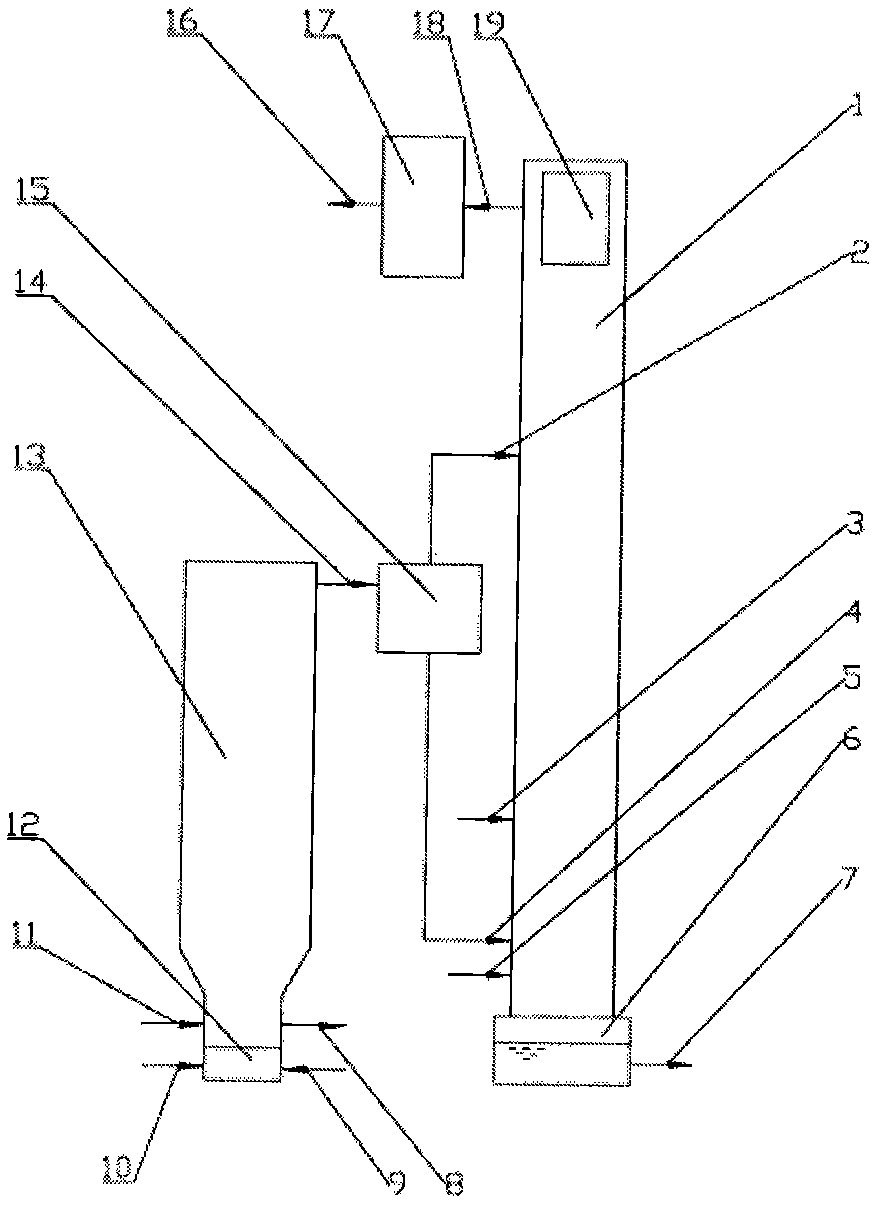

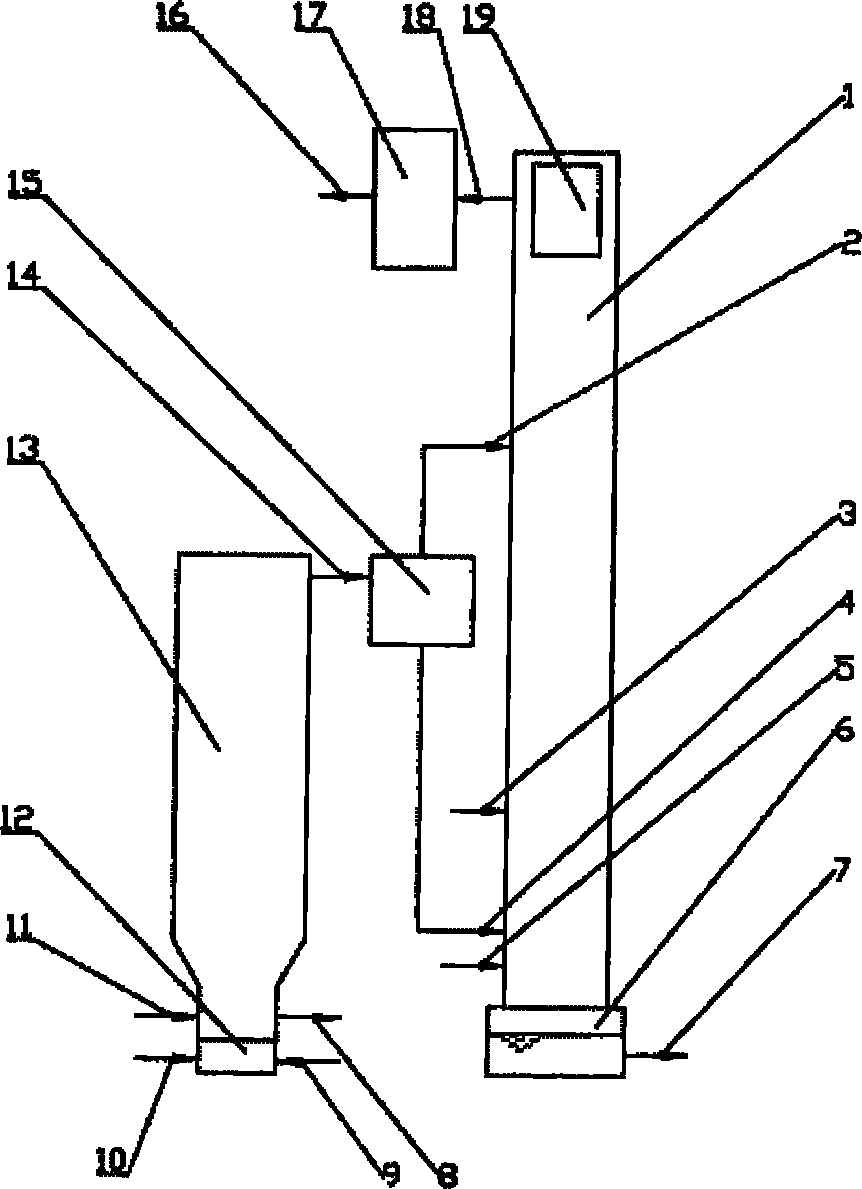

[0067] Such as figure 1 As shown in the process flow chart, the raw coal is fed into the lower space of the fluidized bed gasification furnace 13 through the coal inlet 11, and the molar ratio of hot air and steam at a temperature of 100-800°C is 3:1-15:1, and the fluidized The hot air pipe 10 of the bed gasifier and the steam pipe 9 of the fluidized bed gasifier enter the air distribution chamber 12, and then enter the lower space of the fluidized bed gasifier 13 from the air distribution chamber 12. The oxygen content of the hot air is between the oxygen content of pure air and pure oxygen (that is, 21% to 99.2% by mole, preferably 21% to 75%), and the oxygen content required for raw coal gasification is the same as It is related to the coal quality analysis of coal. Generally, the molar ratio of oxygen to carbon is 0.9-1. The hot air and steam undergo violent heat exchange and chemical reaction in the lower space of the fluidized bed gasifier 13 in the range of 850-1000°C,...

Embodiment 2

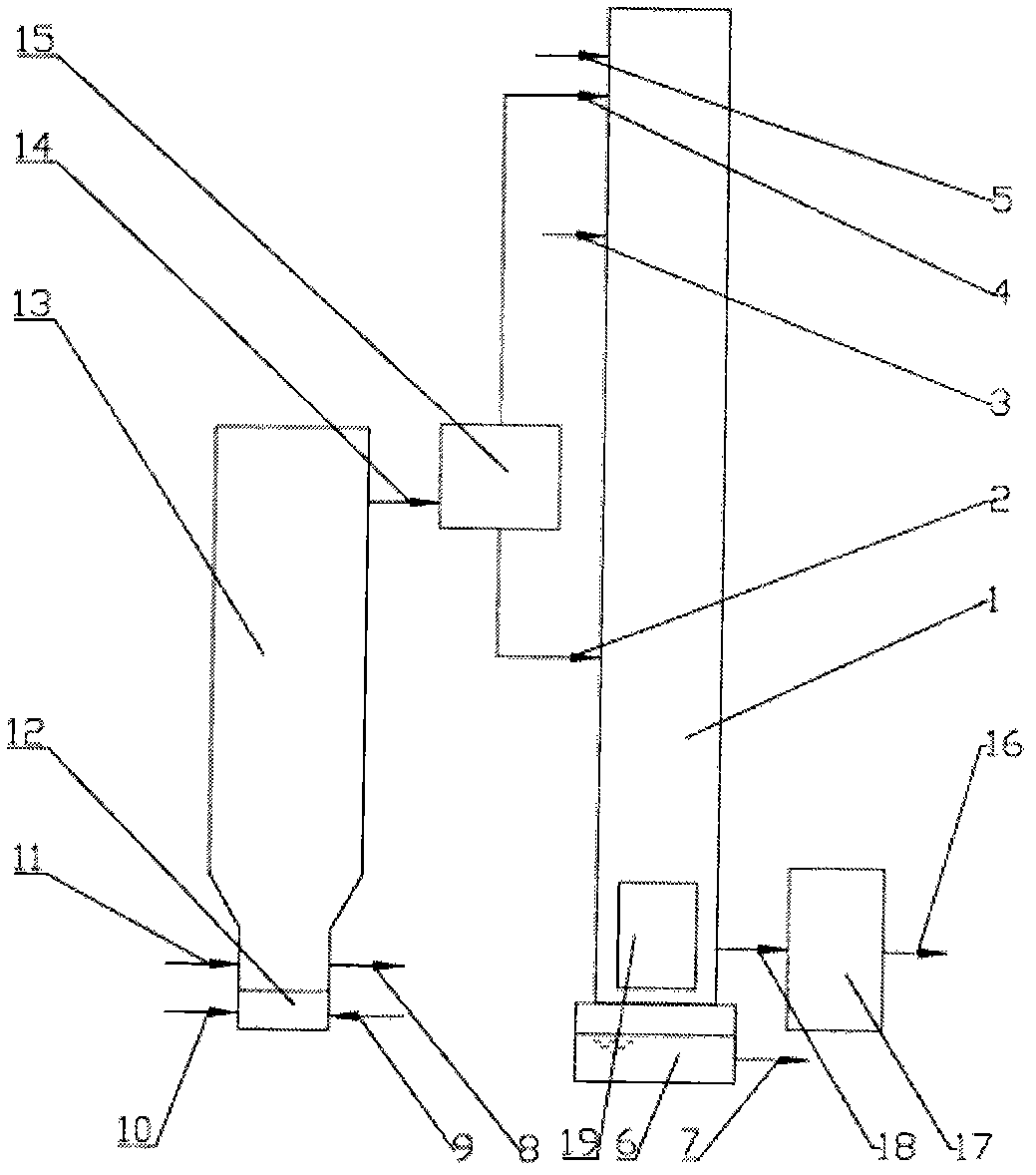

[0078] Such as figure 2 As shown in the process flow chart, the raw coal is fed into the lower space of the fluidized bed gasifier 13 through the coal inlet 11, and the molar ratio of oxygen and steam at a temperature of 100-800°C is 1-3, and the oxygen and steam of the fluidized-bed gasifier are supplied respectively. The pipe 10 and the steam pipe 9 of the fluidized bed gasifier enter into the air distribution chamber 12, and then enter the lower space of the fluidized bed gasifier 13 from the air distribution chamber 12. Oxygen and steam undergo intense heat exchange and chemical reactions in the lower space of the fluidized bed gasifier 13, and the generated gas carries small particles of coal and ash up to the upper space of the fluidized bed gasifier 13 with the air flow to continue the reaction. The reaction temperature is 800 In the range of ~2000°C, part of the ash is discharged out of the furnace through the slag discharge pipe 8 of the fluidized bed gasifier. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com